Intelligent tour inspection device for feeder cable channel

A transmission cable and intelligent inspection technology, which is applied in the field of intelligent inspection devices for transmission cable channels, can solve problems such as low efficiency of fault handling, difficulties in cable fault detection and fault location, and inability to accurately judge faults, so as to improve passability, Small size and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

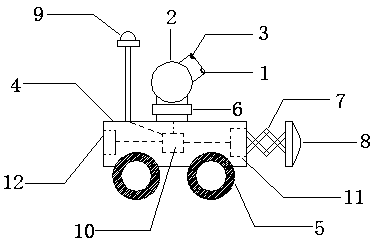

[0024] like figure 1 and figure 2 As shown, put the main body 1 into the cable channel that needs to be inspected after starting, the main body 1 raises the pan-tilt 6, at this time, the rotatable camera 2 installed on the pan-tilt 6, and the infrared measuring device installed at the camera end Temperature device 3 and searchlight 1 start working, and searchlight 1 provides light source for rotatable camera 2, and the imaging quality of rotatable camera 2 can be improved by using cloud platform 6; Internal rotation ensures that there is no dead point in the inspection process, and the collected video and temperature signals are sent to the control panel 10, and the control panel 10 remotely and wirelessly sends the data to the handheld console 14 through the built-in data transmission module. Relevant information is displayed on the 13, and faults can be found in time, which is convenient for research and analysis.

Embodiment 2

[0026] like figure 1 As shown, when the body 1 is moving forward, if there is an obstacle in front of it, if it is too late to avoid it, the telescopic plate 7 that is movable and arranged at the front end of the body 1 will first contact the obstacle to play a buffering role to prevent the body 1 from being hit. The front end is provided with a buffer pad 8, which can avoid damage to obstacles that may be formed by equipment. The telescopic plate 7 adopts a scissors structure, with small gaps, small space occupation, easy folding, and strong structure; when a small obstacle is found in front, The handheld console 10 remotely sends instructions to the control panel 10, and the control panel 10 controls the telescopic plate 7 through the telescopic drive device 11 to push away the small obstacles in front to continue moving forward.

Embodiment 3

[0028] like figure 1 As shown, when the environment is complex and the line of sight is blocked, the laser radar 9 can be activated to accurately obtain the three-dimensional information of the object, which can be used to analyze the fault and continue to travel, avoiding collisions with internal equipment. When encountering complex terrain, due to each drive The wheel 5 adopts an independent lifting structure, which can adapt to different complex terrains and greatly improve the passability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com