Linear motor with flange edge structure

A linear motor and coil technology, applied in the field of motors, can solve the problems affecting the overall performance of the motor, poor motor vibration effect, unreasonable design, etc., to improve the service life and application range, improve the vibration amount, high safety and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

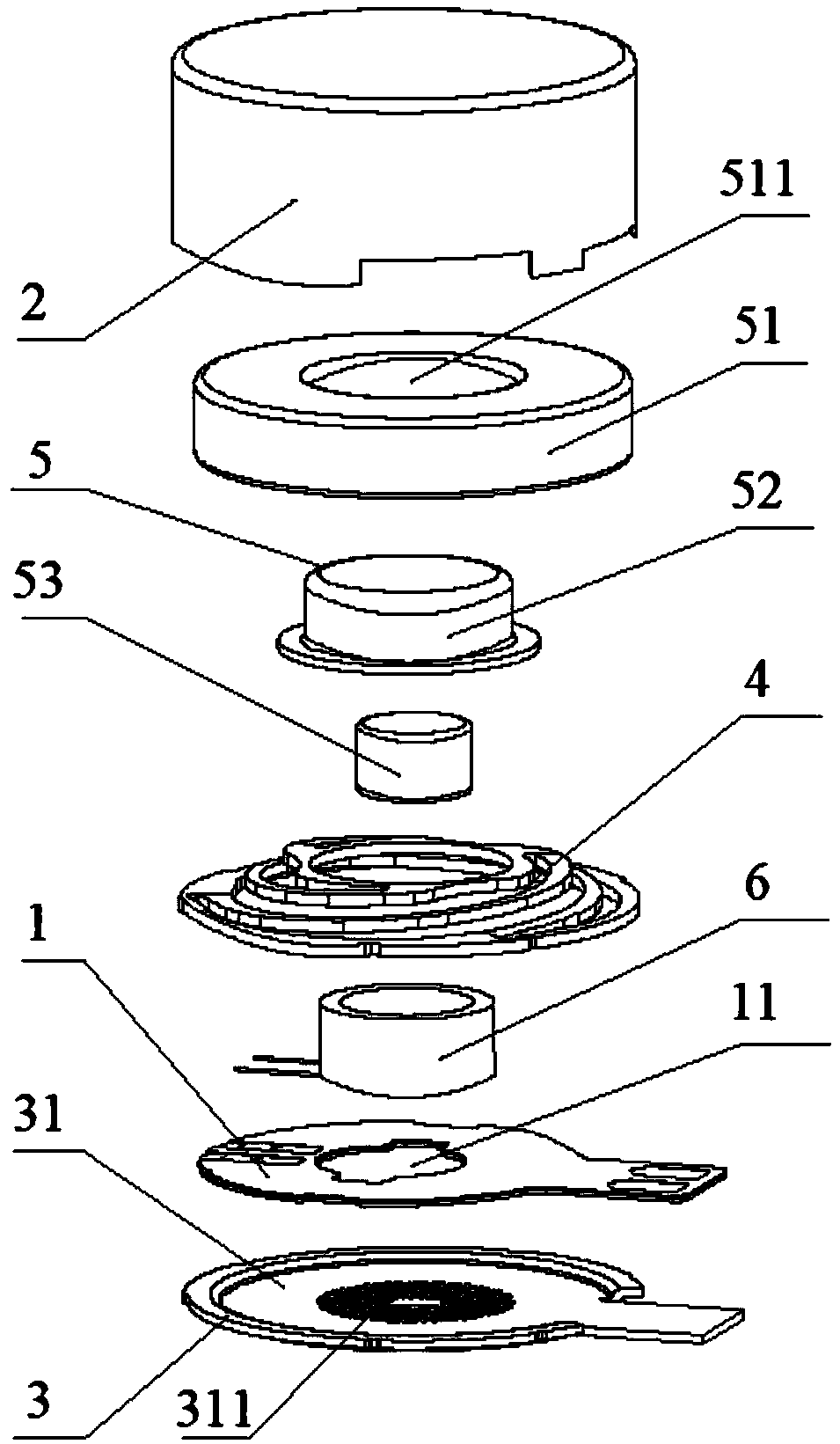

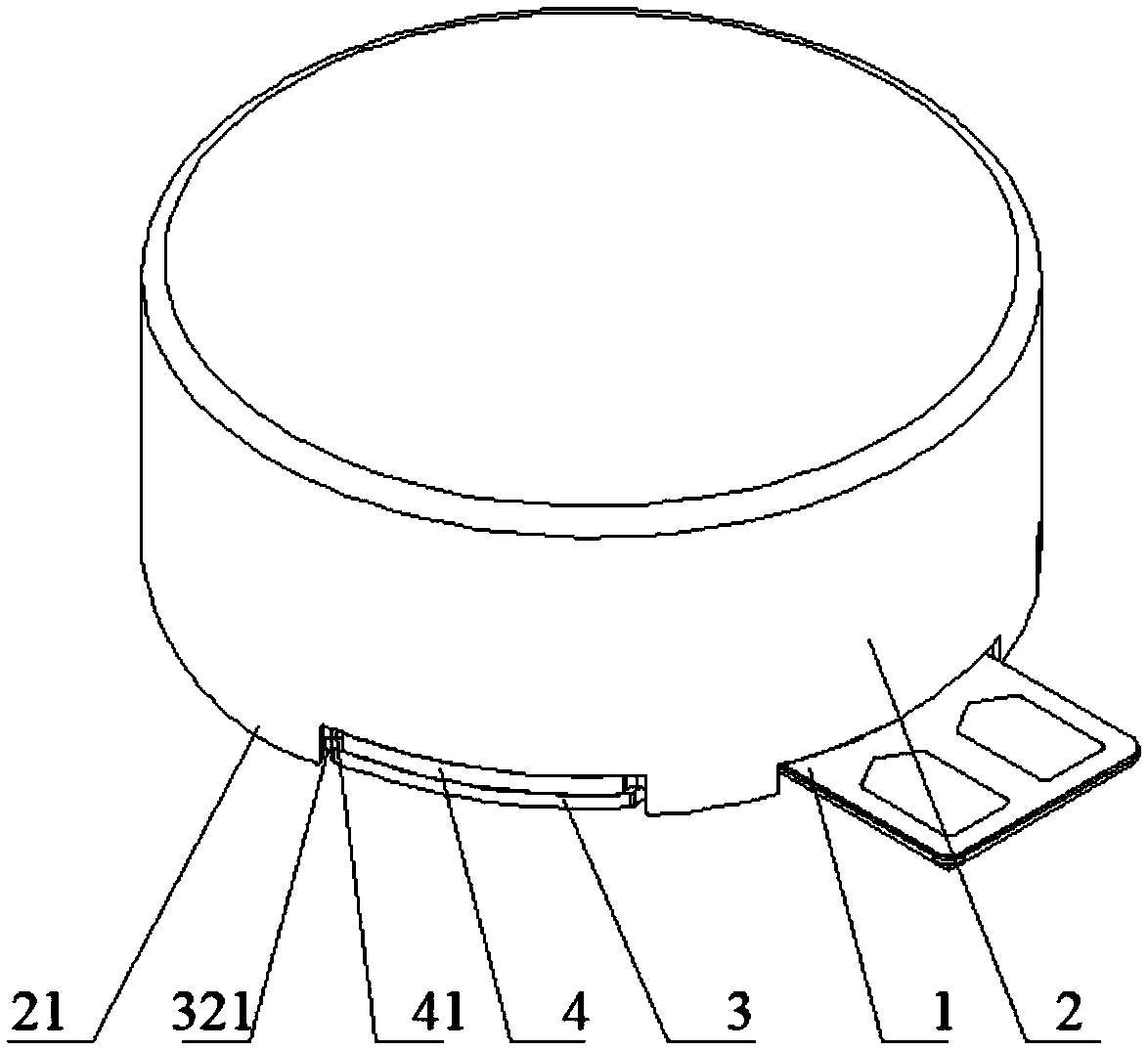

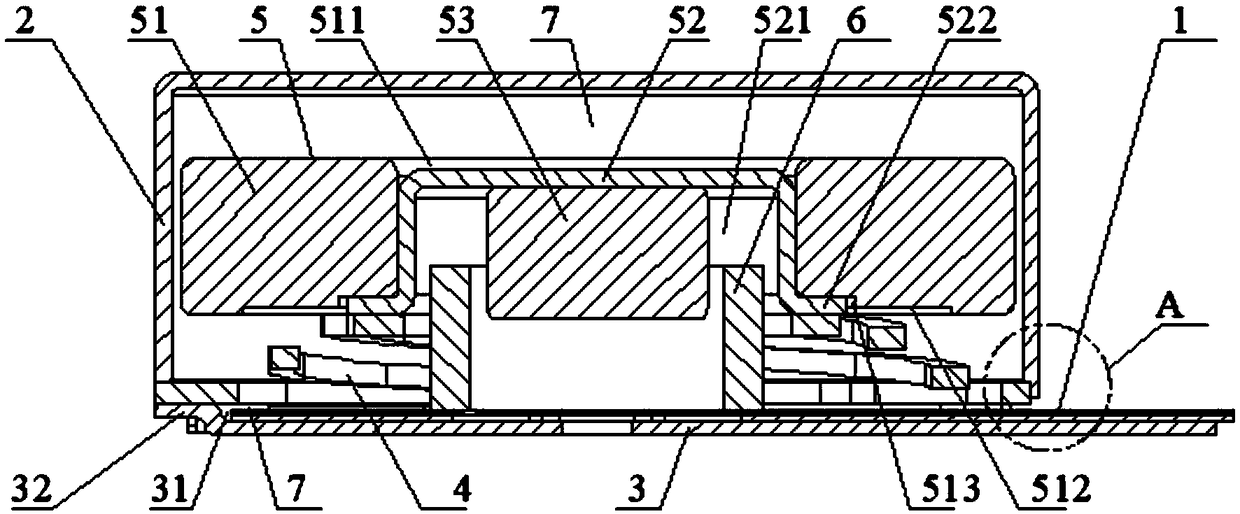

[0031] A linear motor with a flanged side structure such as Figure 1~6 , Figure 8 As shown, it includes an upper casing 2 and a lower casing 3, and the upper casing 2 and the lower casing 3 are provided with a spring 4, a moving subassembly 5, a coil 6 and an FPC board 1, and the spring 4 is located between the lower casing 3 and the moving Between the subassemblies 5, the upper end of the spring 4 is welded to the moving subassembly 5, and the lower cover 3 is provided with a first groove 31 for placing the FPC board 1, usually the FPC board 1 is glued to the lower cover 3, The upper end of the lower machine cover 3 is formed with a first flange 32 matching the spring 4 and the upper casing 2, the lower end of the spring 4 is welded to the first flange 32, and the outer side of the first flange 32 is provided with Several second grooves 321, the outside of the spring 4 is provided with some third grooves 41 corresponding to the second grooves 321, and the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com