Blowing device

A technology of air supply device and air supply channel, which is applied in the direction of the device for coating liquid on the surface, the arrangement of drying gas, and the dryer, etc. Problems such as the influence of degree and the effect of plate coating, etc., to achieve the effect of reducing the amount of spillage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

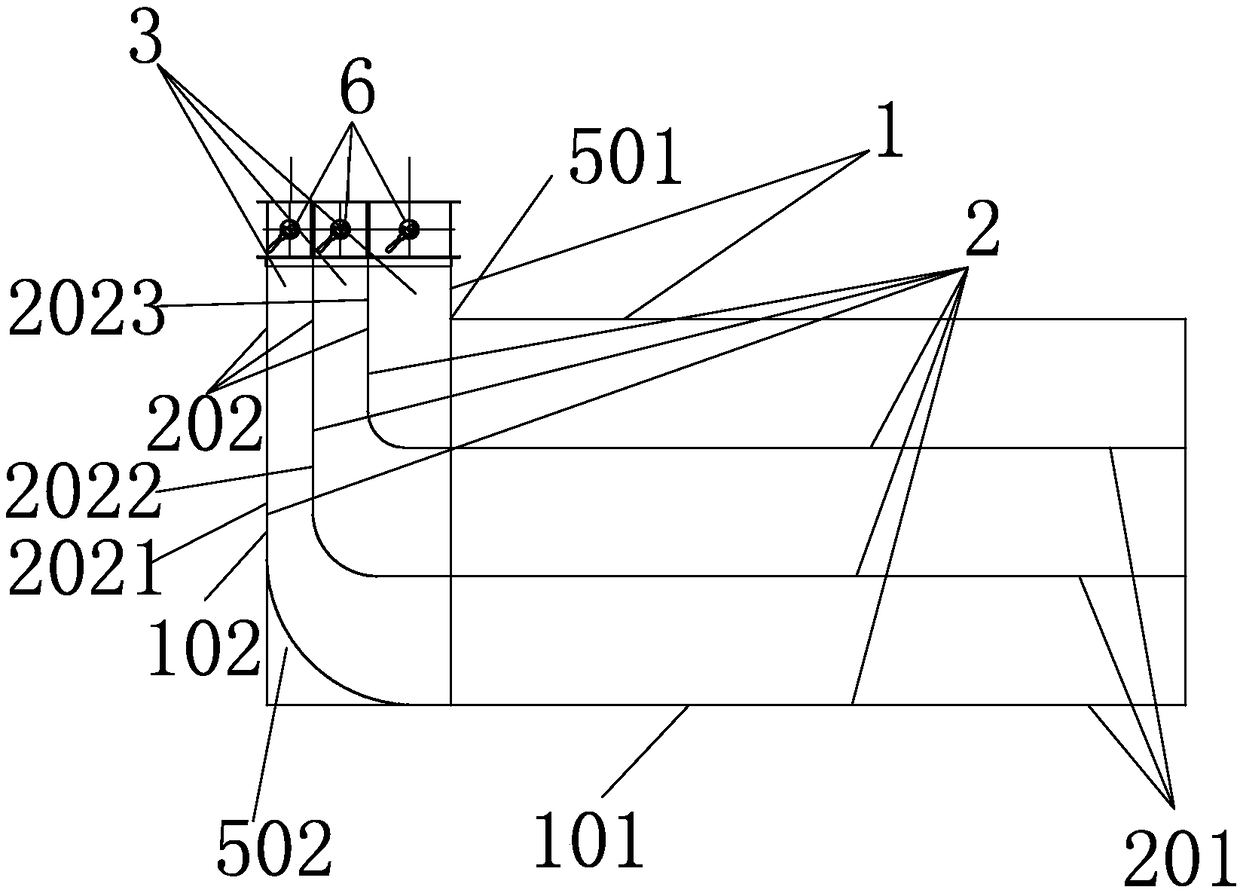

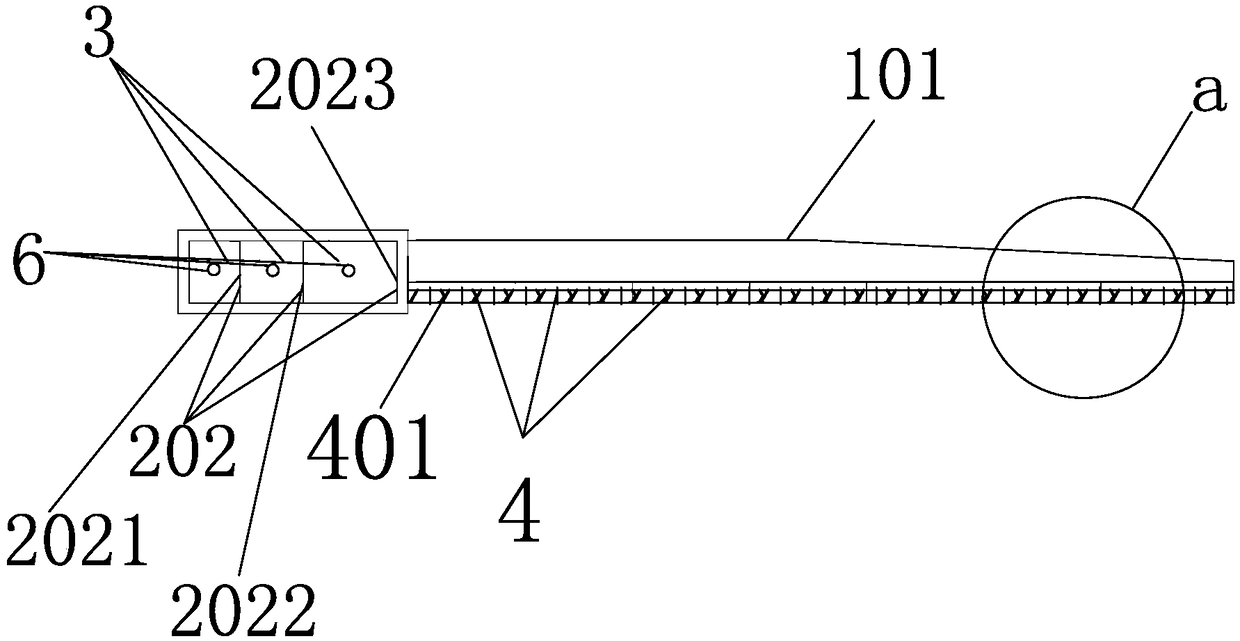

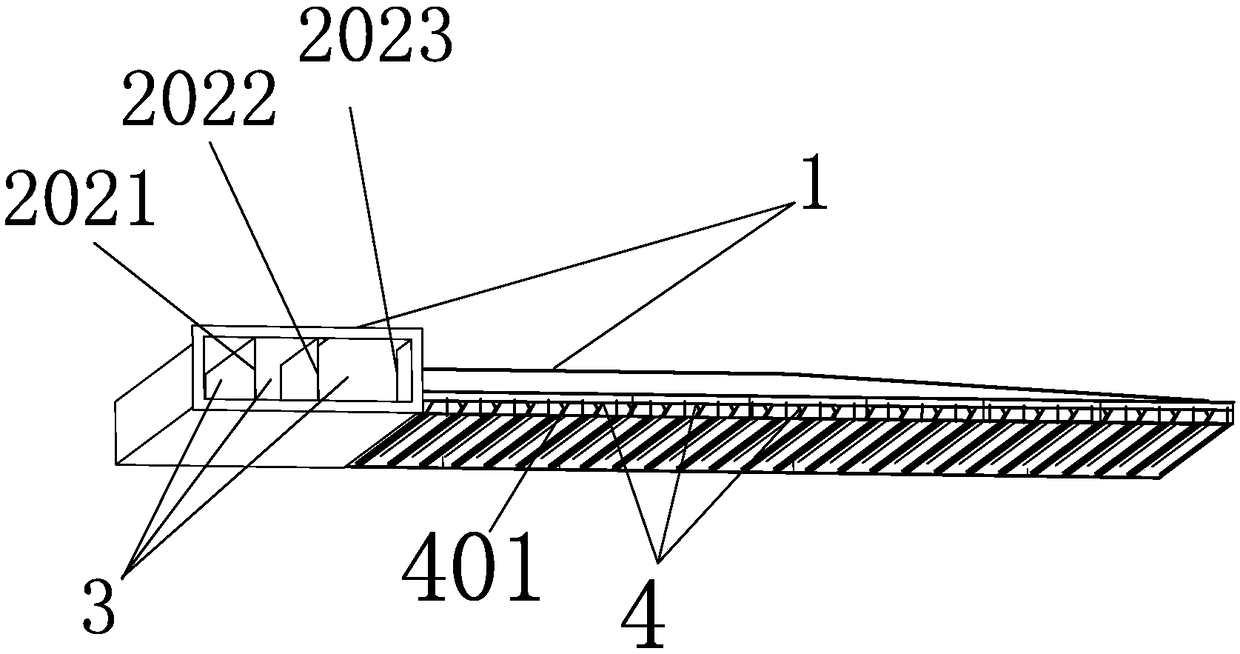

[0035] Such as Figures 1 to 4 An air supply device is shown, the air supply device is composed of a hollow L-shaped shell 1 and three L-shaped partitions 2 arranged vertically side by side in the shell, and the three L-shaped partitions 2 Divide the L-shaped shell 1 into three air inlet channels 3, the L-shaped shell 1 includes a vertical long shell 101 and a short shell 102, and the L-shaped partition 2 includes a vertical long plate 201 and a short plate 202. The lower part of the shell 101 is provided with a plurality of laterally spaced and side by side air supply knives 4, and an air supply channel 401 is formed between adjacent air supply knives 4; the bottom surface of the long shell 101 of the L-shaped shell 1 is open, and the front end of the short shell 102 is open. The remaining surfaces of the shell 1 are closed; a turn is formed between the long shell 101 and the short shell 102, the turn includes an inner turn 501 and an outer turn 502, and an arc transition is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com