A Mechanical Correction Method for Installation Errors of Air Data System Sensors

A technology of atmospheric data and installation error, applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve the problems of the reference offset of the whole machine, inoperability, and the installation state is not stable enough, and achieve the effect of solving the installation out of tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

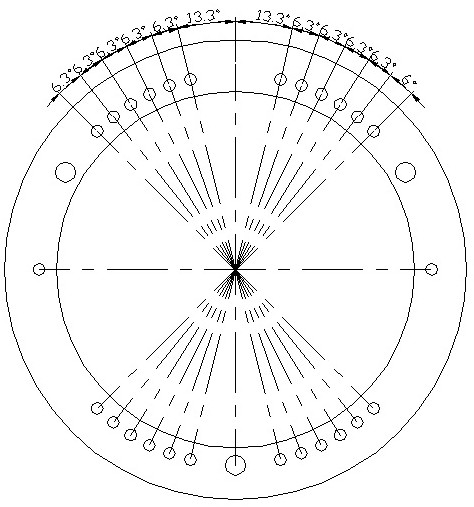

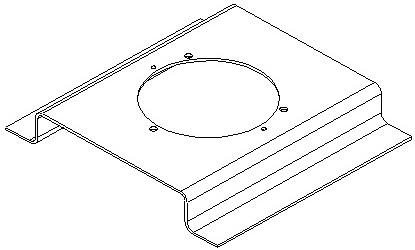

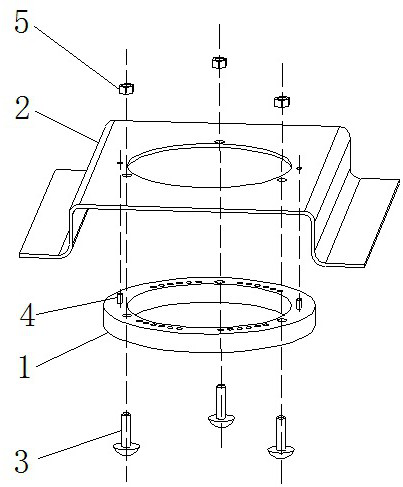

[0027] Attached below Figure 1~8 The present invention is described in detail: a kind of installation error mechanical correction method for air data system sensor:

[0028] The correction method consists of datum transfer and repositioning;

[0029] A. The reference transfer includes the design and manufacture of the reference transfer mold, using the reference transfer mold to realize the transfer of the positioning pin hole reference on the bracket;

[0030] B. The positioning holes on the benchmark transfer mold are set based on the position of the positioning pin holes on the bracket;

[0031] C. The reference transfer makes full use of the original positioning holes of the bracket parts. Based on the original positioning holes of the bracket parts, compare the measured error value δ, and select the corrected positioning pin hole with the reverse value on the reference transfer mold nearby;

[0032] D. Repositioning includes the design and manufacture of the reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com