Temperature isostatic press furnace temperature uniformity optimization device and optimization method thereof

A warm isostatic press and furnace temperature technology, which is applied in the direction of furnace control devices, presses, furnaces, etc., can solve problems such as uneven furnace temperature, and achieve the effect of achieving temperature uniformity and ensuring temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

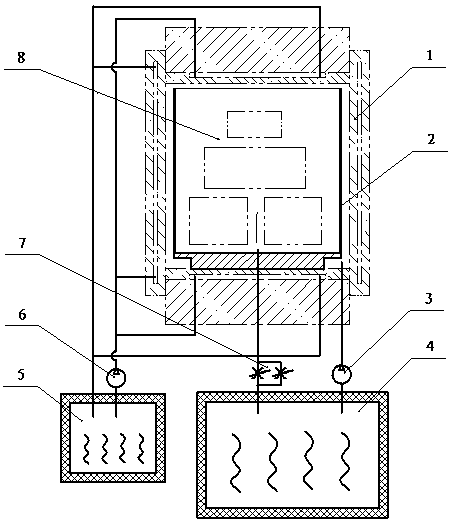

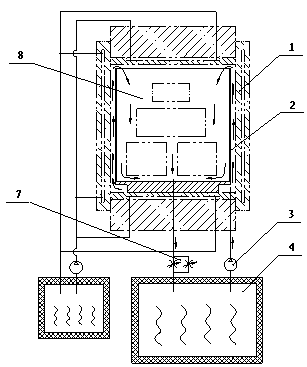

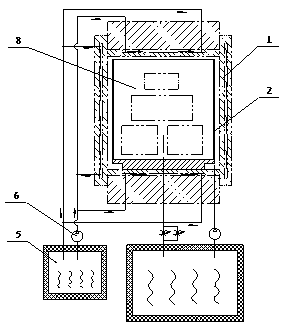

[0016] see figure 1 , the device for optimizing the temperature uniformity of the furnace chamber of a warm isostatic press of the present invention includes a pressure vessel 1, and is characterized in that: a heater 4 for heating the working medium is arranged outside the pressure vessel 1, and a working medium is arranged at the bottom of the pressure vessel 1 The inlet and outlet of the heater 4 communicate with the inlet and outlet of the working medium provided at the bottom of the pressure vessel 1, and a supercharger 3 is arranged between the heater 4 and the inlet of the working medium of the pressure vessel 1 A combined pressure relief valve 7 is provided between the heater 4 and the outlet of the working medium of the pressure vessel 1 .

[0017] Further, in the pressure vessel 1 of the warm isostatic press, a draft tube 2 surrounding the workpiece is arranged.

[0018] Further, a tracer 5 for heating the heat-insulation medium is arranged outside the pressure vess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com