Prestress truss structure

A truss structure and prestressing technology, which is applied to truss structures, truss beams, building structures, etc., can solve the problems of reduced overall rigidity, increased steel consumption, and structural deformation, achieving small structural heights and enlarged structures Span, the effect of increasing the span range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

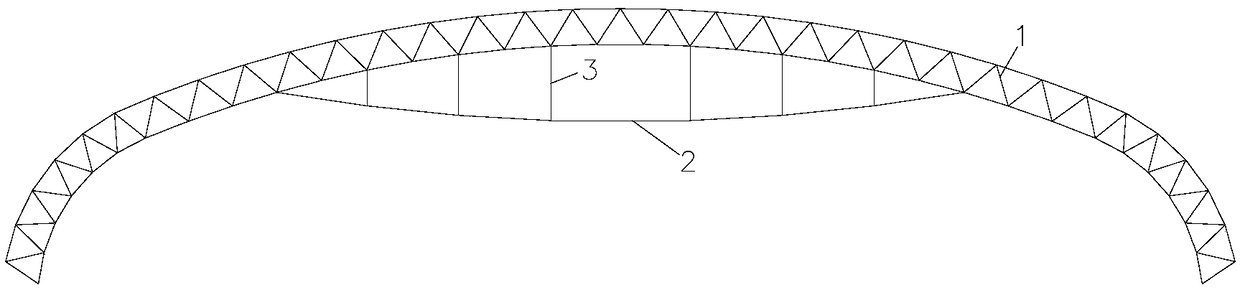

[0024] figure 1 A schematic diagram of an existing arched string tension truss structure is shown, and the existing arch string tension truss structure includes an arch truss 1, a lower string cable 2, and a lower string strut 3, from figure 1 It can be seen that the existing arched string tension truss has only one lower string cable, the two ends of the lower string cable 2 are fixed with the arch truss 1, the upper end of the lower string strut 3 is connected with the arch truss 1, and the lower end of the lower string strut 3 Connect with bottom string 2.

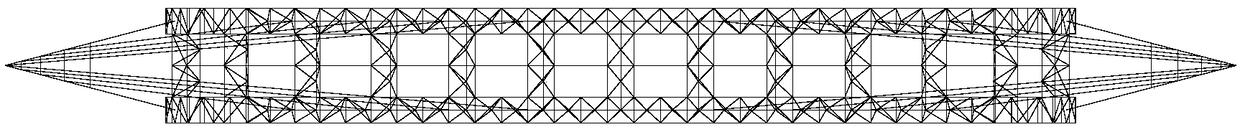

[0025] Figure 2~4 As shown, a prestressed truss structure includes an arched truss 1, lower chord cables 2, lower chord cable braces 3, concrete slanted columns 4, stay cables 5, and secondary trusses 6. Figure 2~4 It can be seen that in this scheme, both ends of the lower string 2 are fixed to the arch truss 1 , the upper end of the lower string strut 3 is connected to the arch truss 1 , and the lower end of the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com