Continuous material pulverizer

A pulverizer and material technology, applied in the field of mechanical transmission, can solve problems such as undiscovered patent documents, achieve the effects of saving manpower, intelligent and convenient operation process, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

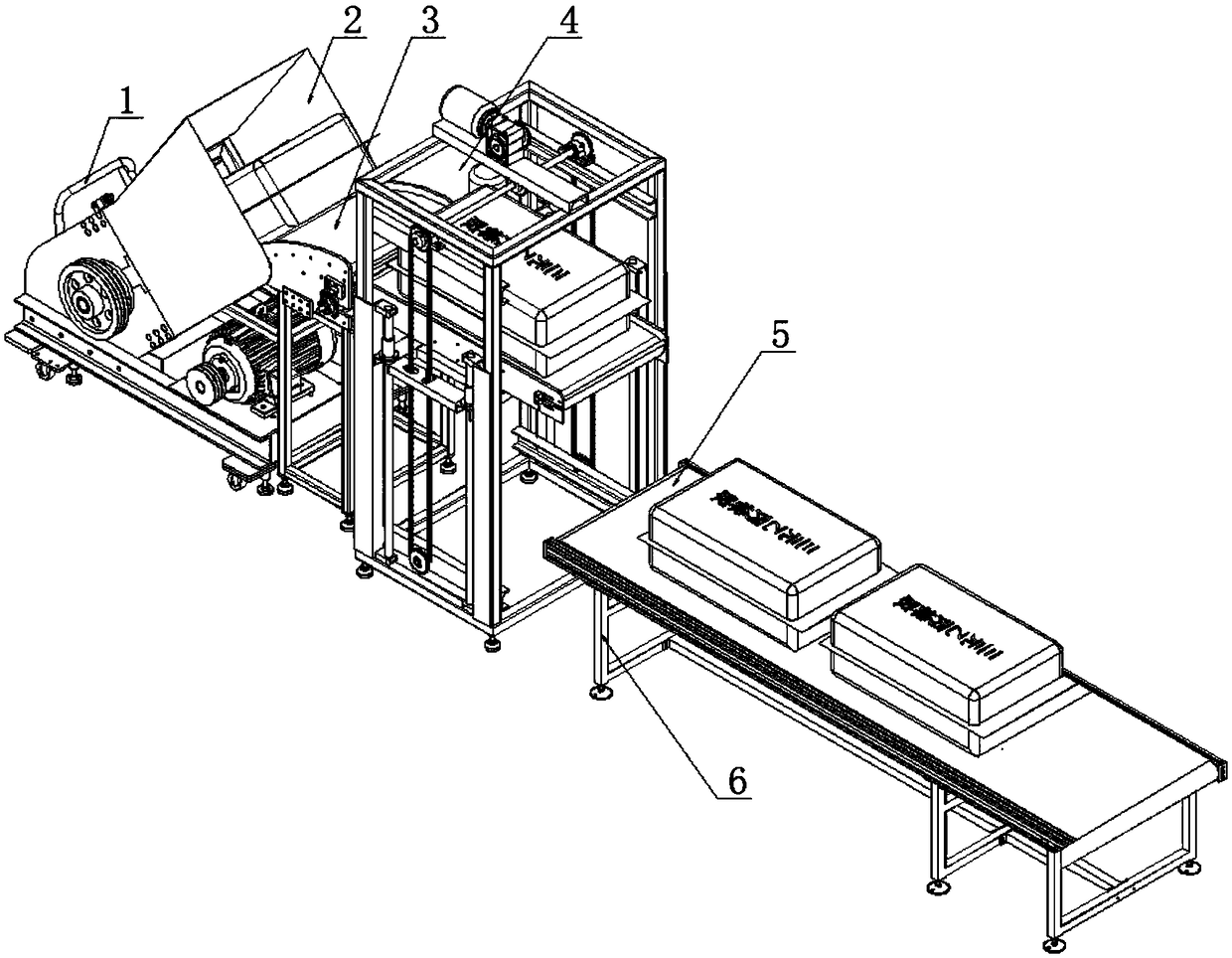

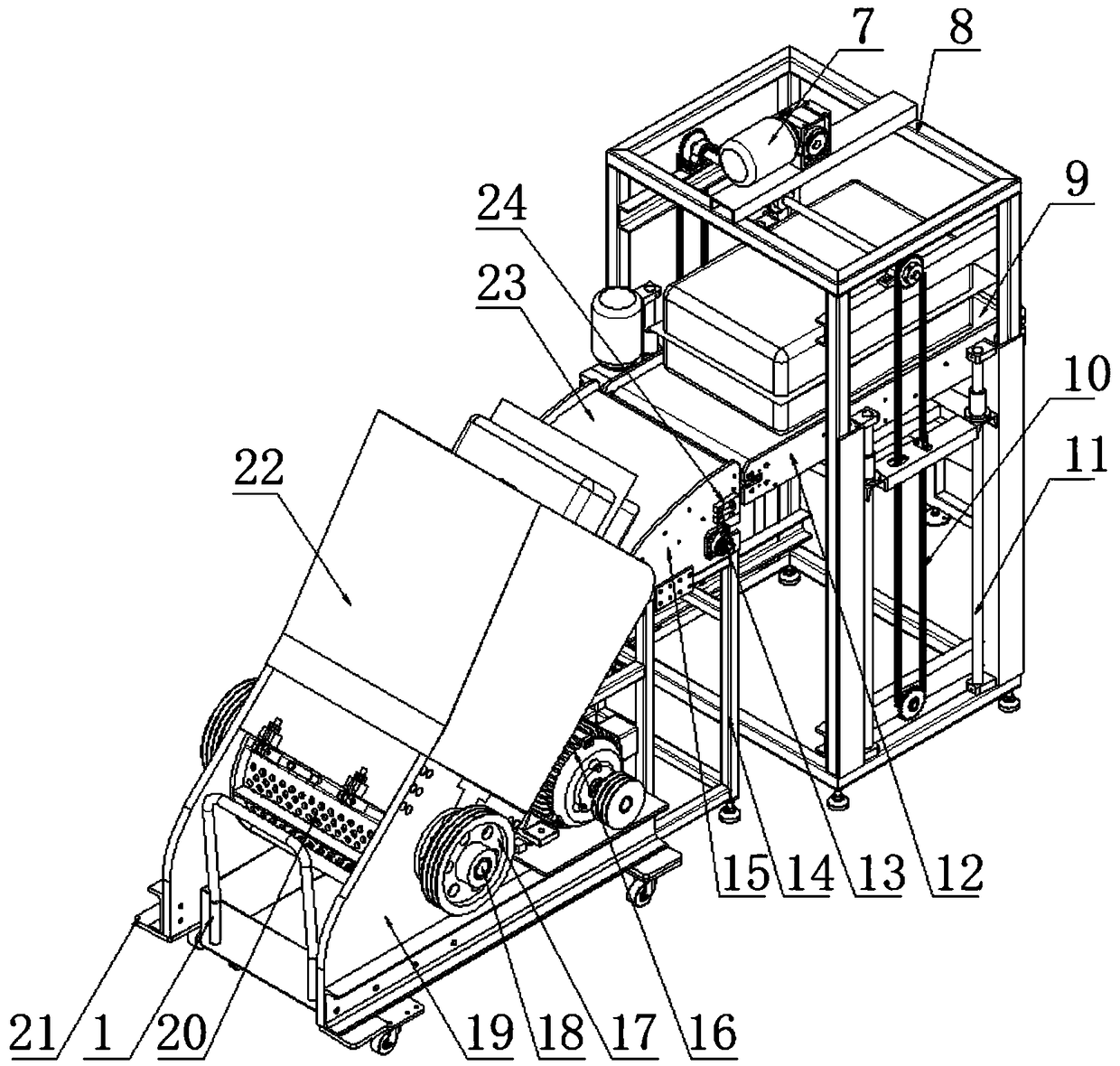

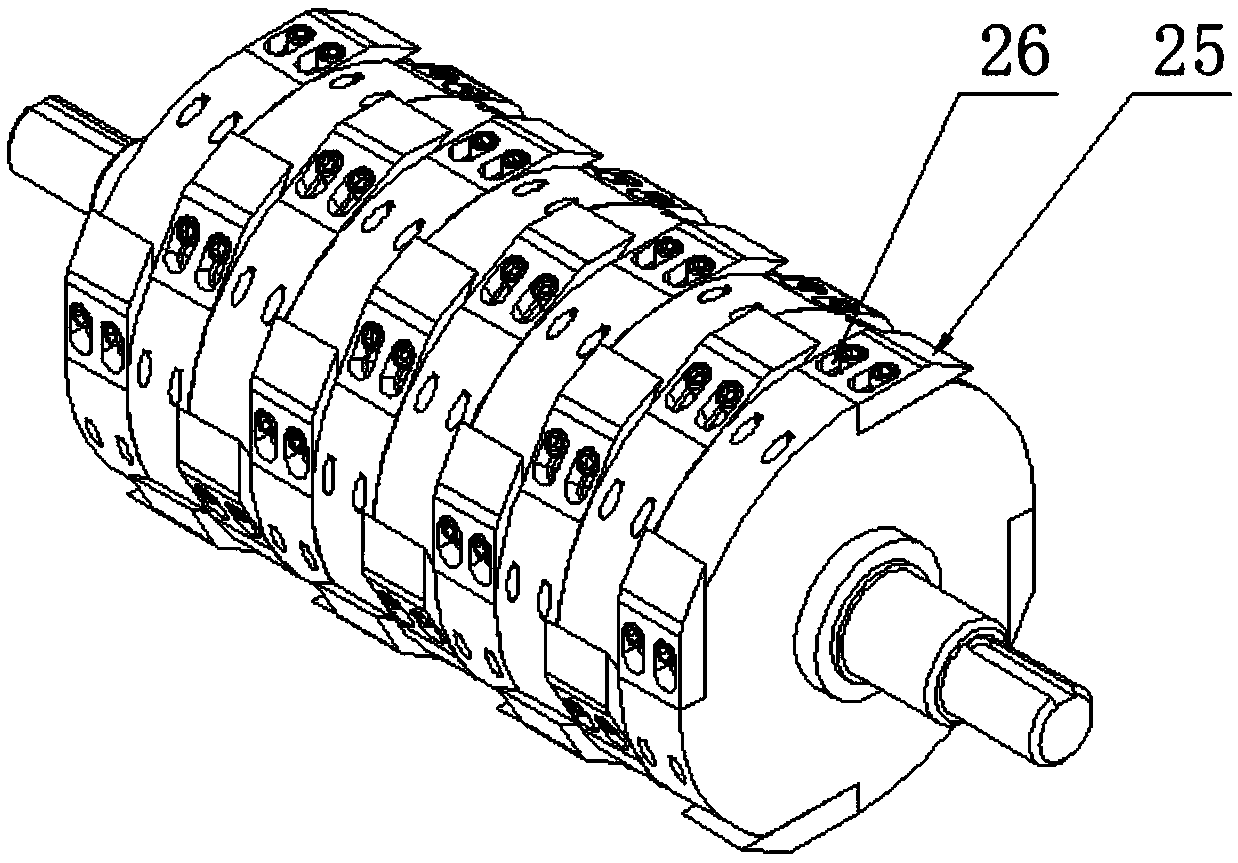

[0031] A continuous material pulverizer, which is innovative in that it includes a material lifting mechanism 4, a material conveying mechanism 3, a material pulverizing mechanism 2, and a mobile receiving vehicle 1. The material lifting mechanism includes a lifting bracket 8, a material lifting platform 12, a lifting Chain wheel and lifting deceleration motor 7, lifting sprocket 10 is installed on the lifting bracket, and the lifting sprocket is connected to the material lifting platform, and the material lifting platform is provided with a feeding belt conveyor 9, and the lifting sprocket is driven by the lifting reducing motor to do linear lifting motion; The conveying mechanism includes a conveying bracket 14, a driving motor 13 and an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com