A method for distributing mold slag in a single-point unbalanced casting special-shaped billet mold

A mold powder and mold powder technology, which is applied in the field of continuous casting mold, can solve the problems of excessive temperature difference, unstable mold powder layer, and uneven dissolution of mold powder, so as to reduce melting point and reduce billet drawing resistance. , The effect of preventing steel leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for distributing mold slag in a single-point unbalanced casting shaped billet crystallizer according to the present invention mainly includes the following steps:

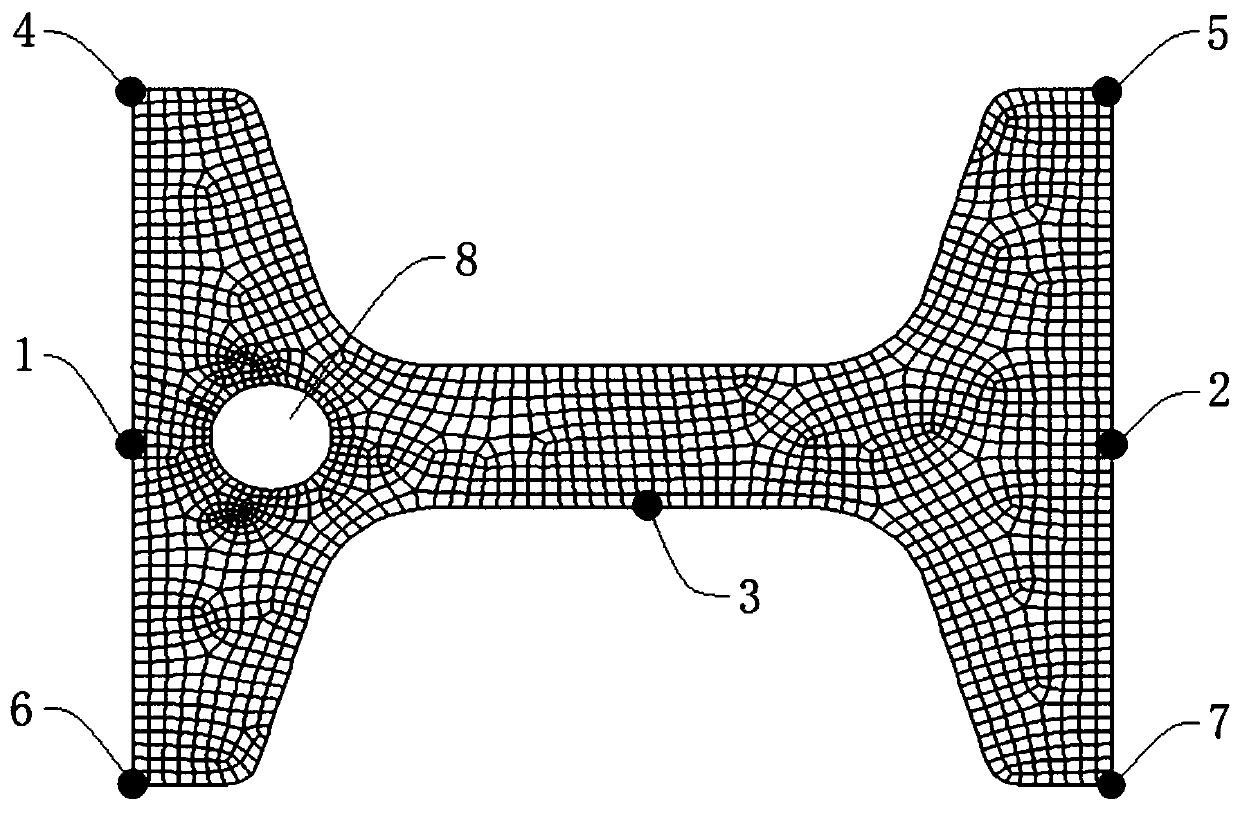

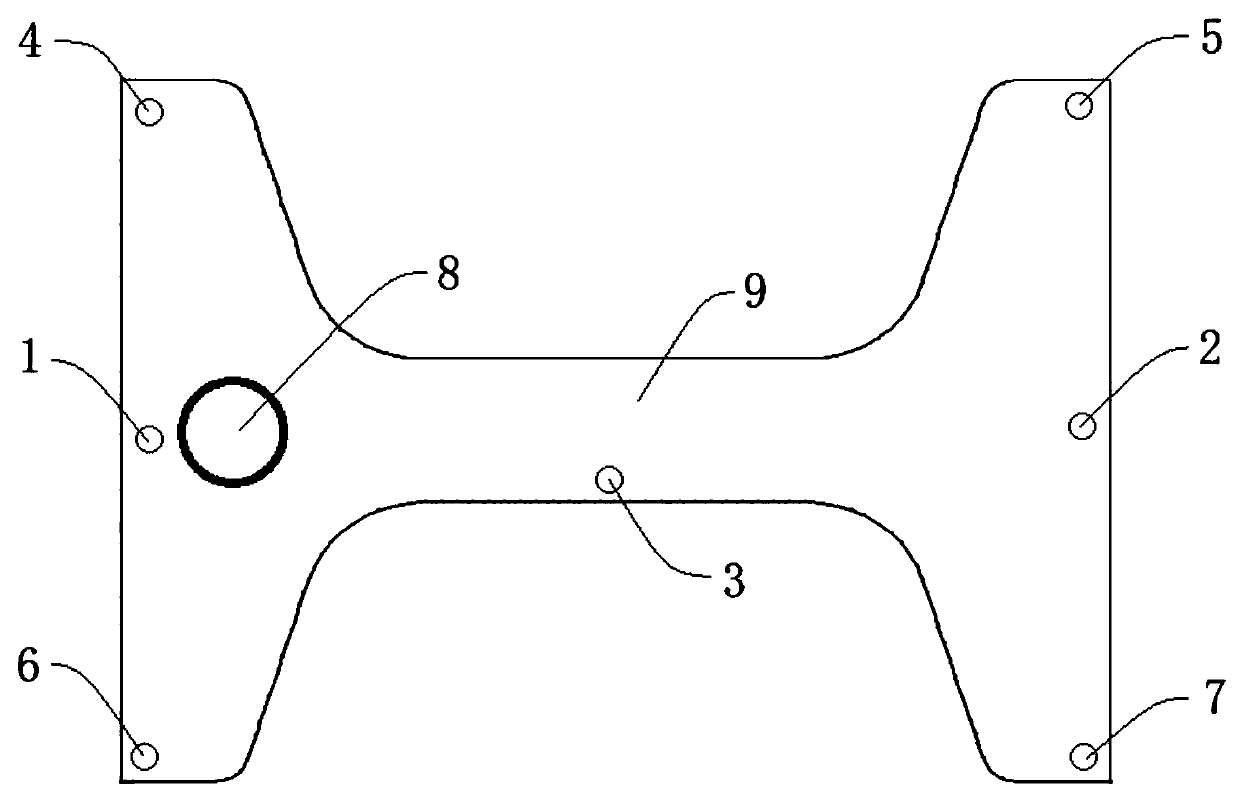

[0046] A. Obtain the model of crystallizer single-point casting through mathematical modeling; figure 1 As shown, it is a top view of the working area of the crystallizer for mathematical modeling. Mathematical modeling does not need to enter the site to measure the production, and in the continuous casting process, it is dangerous and expensive to use instruments to detect the condition of molten steel. It is beneficial to reduce production costs. After the numerical simulation analyzes the on-site production, it conducts mathematical modeling. The simulation results are close to the actual situation, which has certain guiding significance for actual production.

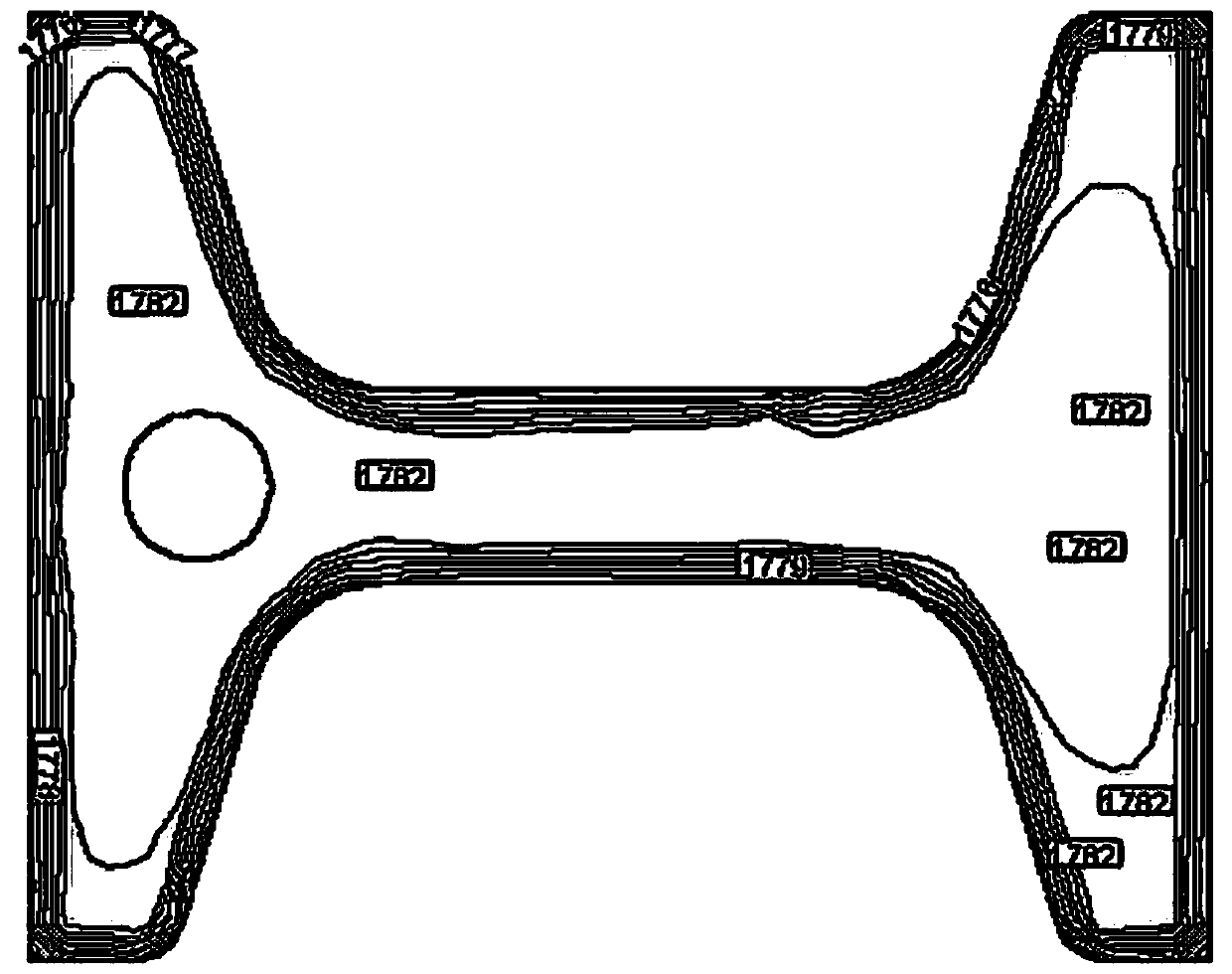

[0047] B. Simulate the mathematical model that has been modeled to obtain the temperature distribution of molten steel on the cross-se...

Embodiment 2

[0057] The steps of this embodiment are the same as that of Embodiment 1, the difference lies in further explaining the present invention and providing support for the present invention.

[0058] The mold flux of the present invention is composed of acidic oxides, basic oxides and fluorides, and carbon black is added to the mold flux as a covering agent. Since the melting point of carbon black is too high, it does not participate in the melting during the whole process, so it can be ignored Into the range of mold flux components, when adding mold flux initially, it can be added according to the proportion, and then it can be added according to the content of carbon black in the crystallizer as the case may be. Fluoride can be CaF 2 , for effectively lowering the melting point, adding CaF to No. ① mold flux and No. ② mold flux 2 The content is the same or similar, which is convenient for the calculation of the melting point of the two mold fluxes.

[0059] In order to facilit...

Embodiment 3

[0070] The procedure of this embodiment is the same as that of Example 2, the difference is that in step D, two compositions of mold flux with different contents and basicity of mold flux are provided.

[0071] Step D. Select two kinds of mold fluxes with different melting points, which are recorded as No. ① mold flux and No. ② mold flux. The melting point of No. ① mold flux is not lower than the melting point of No. ② mold flux; The number is SiO 2 : 32.3 parts, Al 2 o 3 : 18.6 parts, Fe 2 o 3 : 2.0 parts, CaO: 40.8 parts, MgO: 3.4 parts, R 2 O: 2.9 parts; The main component of No. ② mold flux is SiO in parts by weight 2 : 32.3 parts, Al 2 o 3 : 15.9 parts, Fe 2 o 3 : 2.0 parts, CaO: 40.8 parts, MgO: 3.4 parts, R 2 O: 5.6 parts. Add 1.8 parts of CaF to No. ① mold flux and No. ② mold flux according to the weight of the main components 2 and 14.8 parts of carbon black; the basicity R of No. ① mold slag is 0.89, and the basicity R of No. ② mold slag is 0.99.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com