Safe breaking-preventing screw tap chuck

A tap chuck and tap technology, applied in metal processing equipment, tangent devices, manufacturing tools, etc., can solve the problems of quality accident taps, high cost, and the tap cannot be disengaged, and achieve the effect of preventing scrap and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

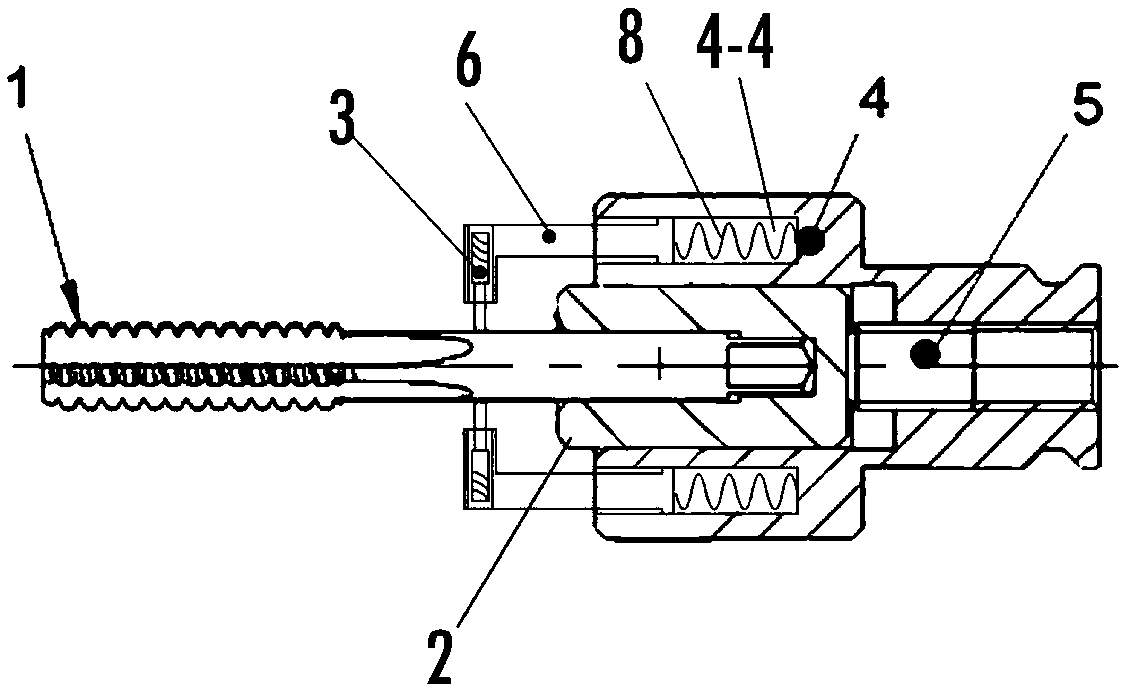

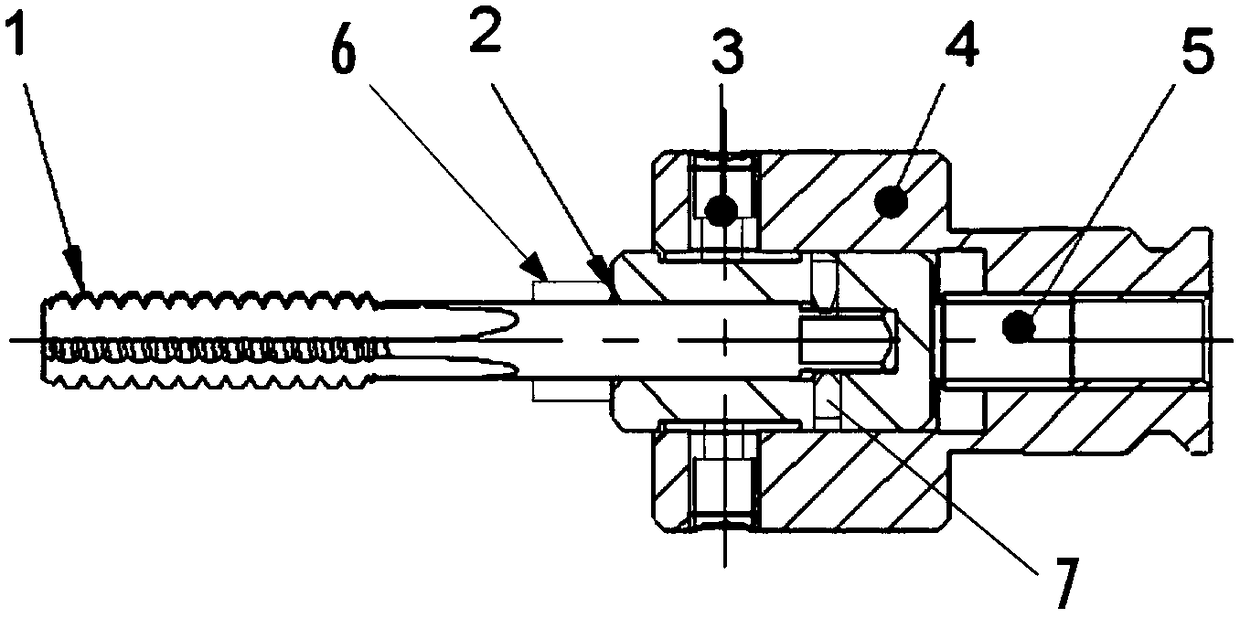

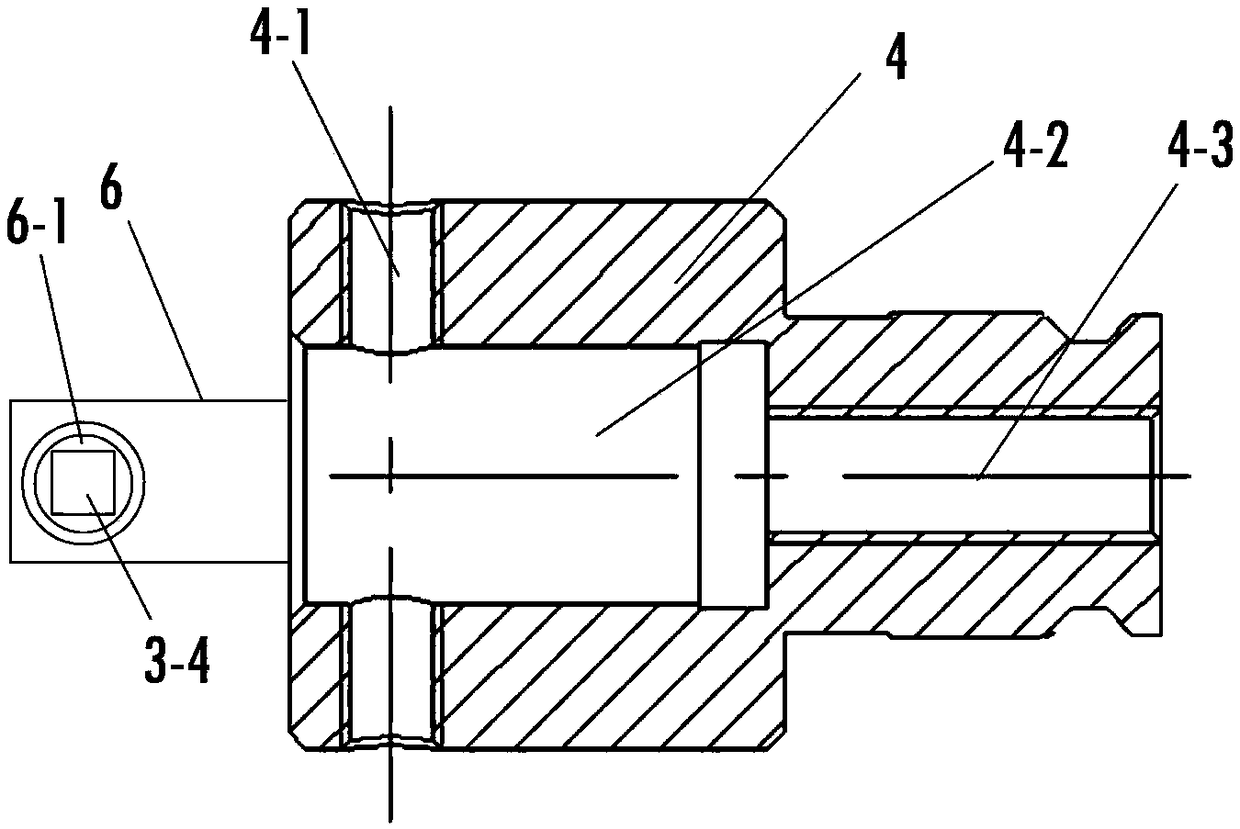

[0020] Such as Figure 1~6 As shown, a safety anti-breaking tap chuck includes a chuck body 4, and also includes a tap sleeve 2, a support arm 6, and a telescopic tightening screw 3. The front center axis of the chuck body 4 is provided with a taper sleeve The fixing groove 4-2 is provided with a longitudinal tightening threaded hole 4-1 on the upper and lower side walls of the taper sleeve fixing groove 4-2; the telescopic tightening screw 3 includes a screw body, and the outer wall of the screw body is provided with The thread 3-1 has a telescopic head groove 3-2 inside; a spring 3-3 and a telescopic head 3-4 are distributed in the telescopic head groove 3-2; the spring 3-3 is distributed in the telescopic head 3-4, and has been pressing outward on the telescopic head 3-4, the telescopic head 3-4 is in the shape of a rectangle, and the telescopic head slot 3-2 matches the telescopic head to ensure that the The telescoping head 3-4 does not rotate during the tightening proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com