Double-knife hot-cutting machine for safety rope

A technology of eager cutting machine and safety rope, which is applied in metal processing and other directions, can solve the problems of slow cutting speed, low working smoothness and low working efficiency, and achieve the effect of ensuring cutting speed, ensuring smooth working and increasing working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

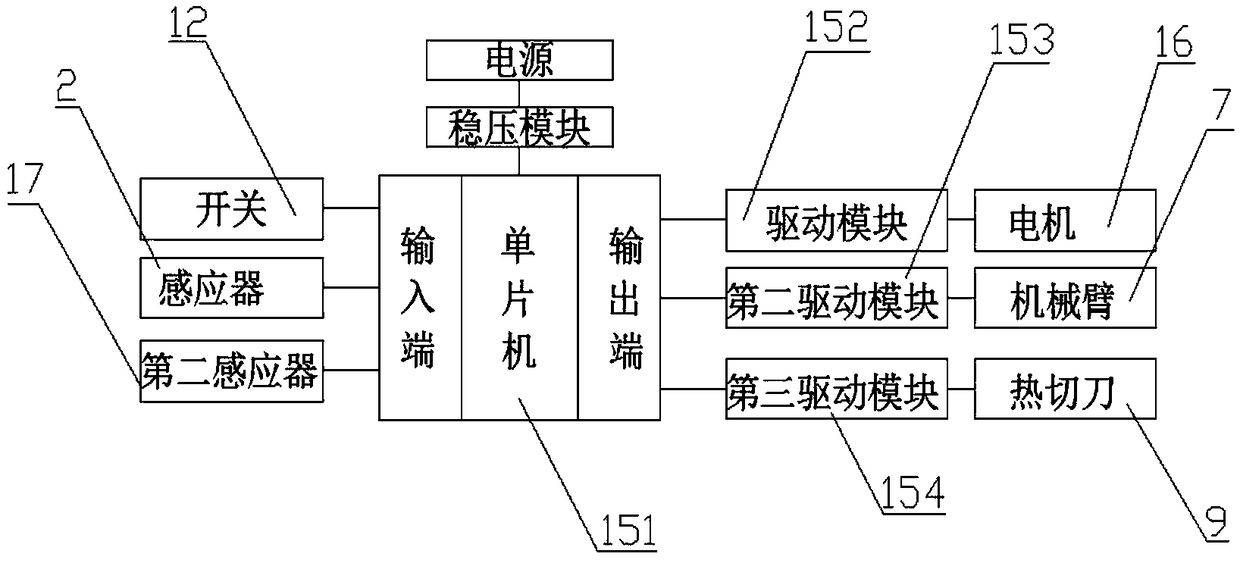

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

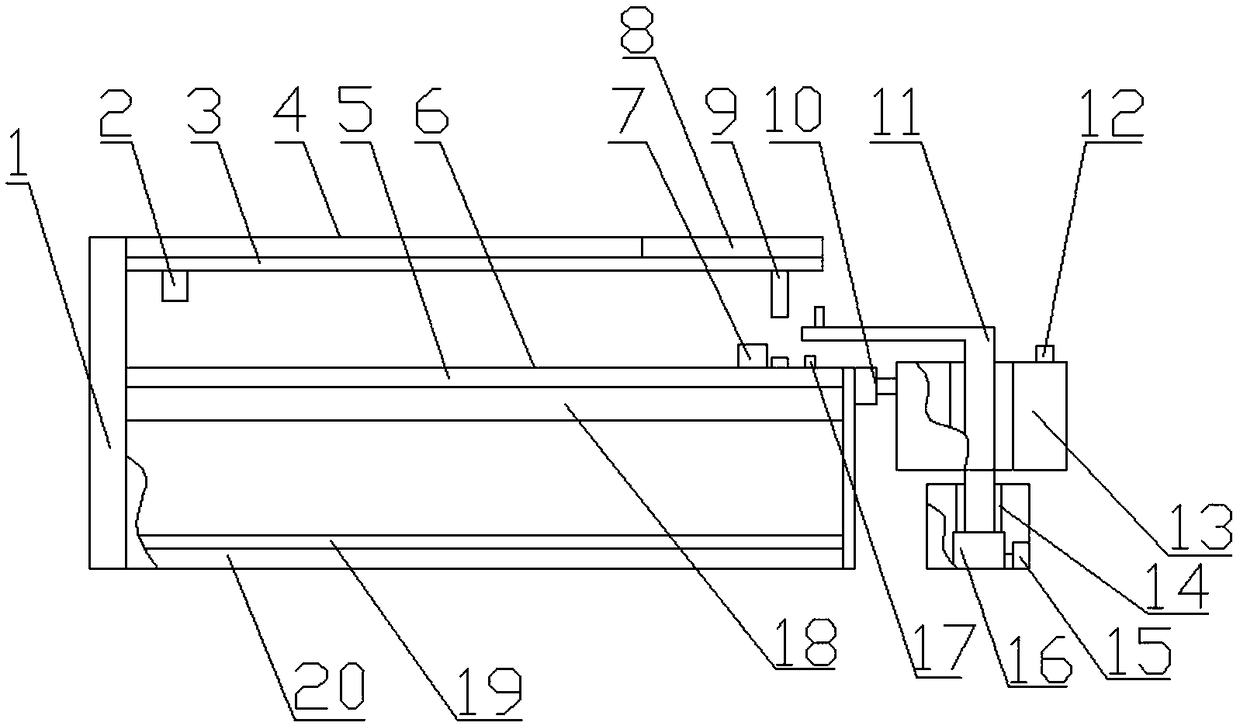

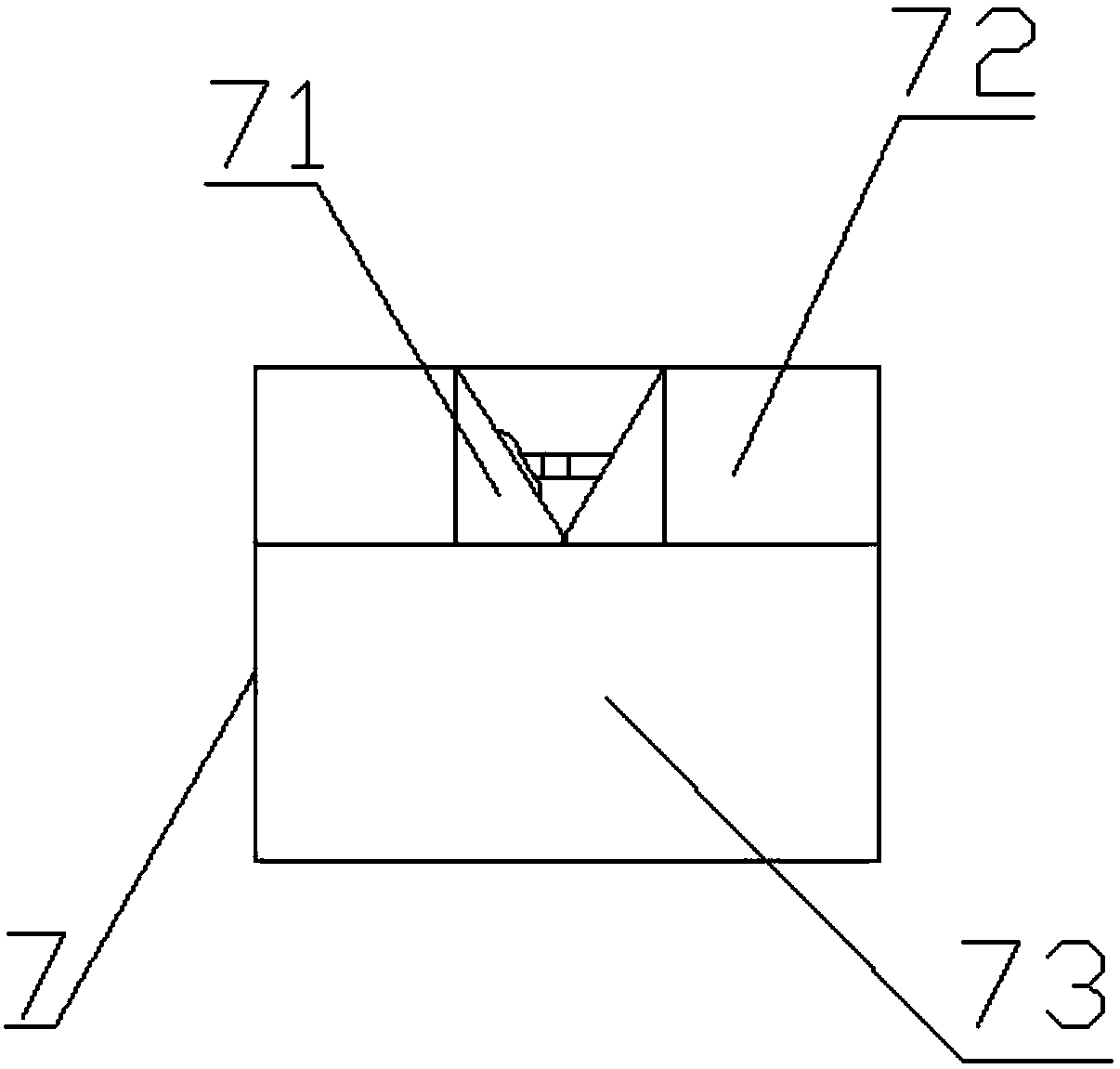

[0023] as attached figure 1 to attach image 3 shown

[0024] The invention provides a safety rope double-knife hot cutting machine, including a side column 1, an inductor 2, a sliding groove 3, an upper stable column 4, an arm sliding area 5, a working area 6, a mechanical arm 7, an electric heating plate 8, and a hot cutting knife 9 , connecting the shrinking rod 10, the rope screw 11, the switch 12, the screw base area 13, the rope setting area 14, the controller 15, the motor 16, the second inductor 17, the transition chamber 18, the drop chamber 19 and the base 20, so The lower end of one side of the side column 1 is connected to the drop chamber 19 through the base 20, and a transition chamber 18 is provided above the drop chamber 19, and an arm sliding area 5 is arranged above the transition chamber 18; The surface is provided with a working area 6, and the rear end of the arm sliding area 5 is provided with a mechanical arm 7, and the rear of the mechanical arm 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com