Fixed mold quick-changing mold structure of foam plastic automatic molding machine

A technology for automatic molding machines and foam plastics, which is applied in the field of quick-change mold structures for automatic foam plastic molding machines. Molding time, the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

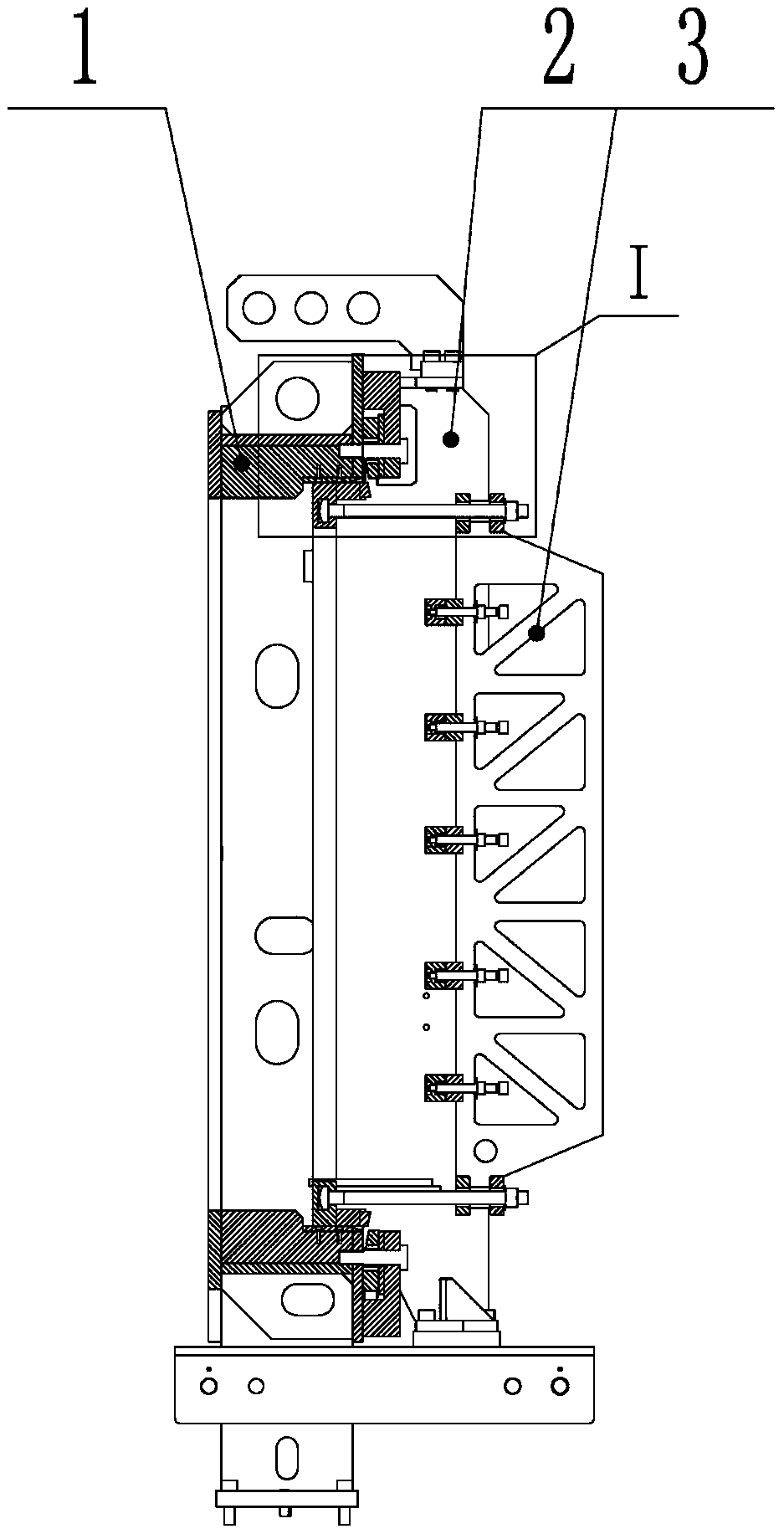

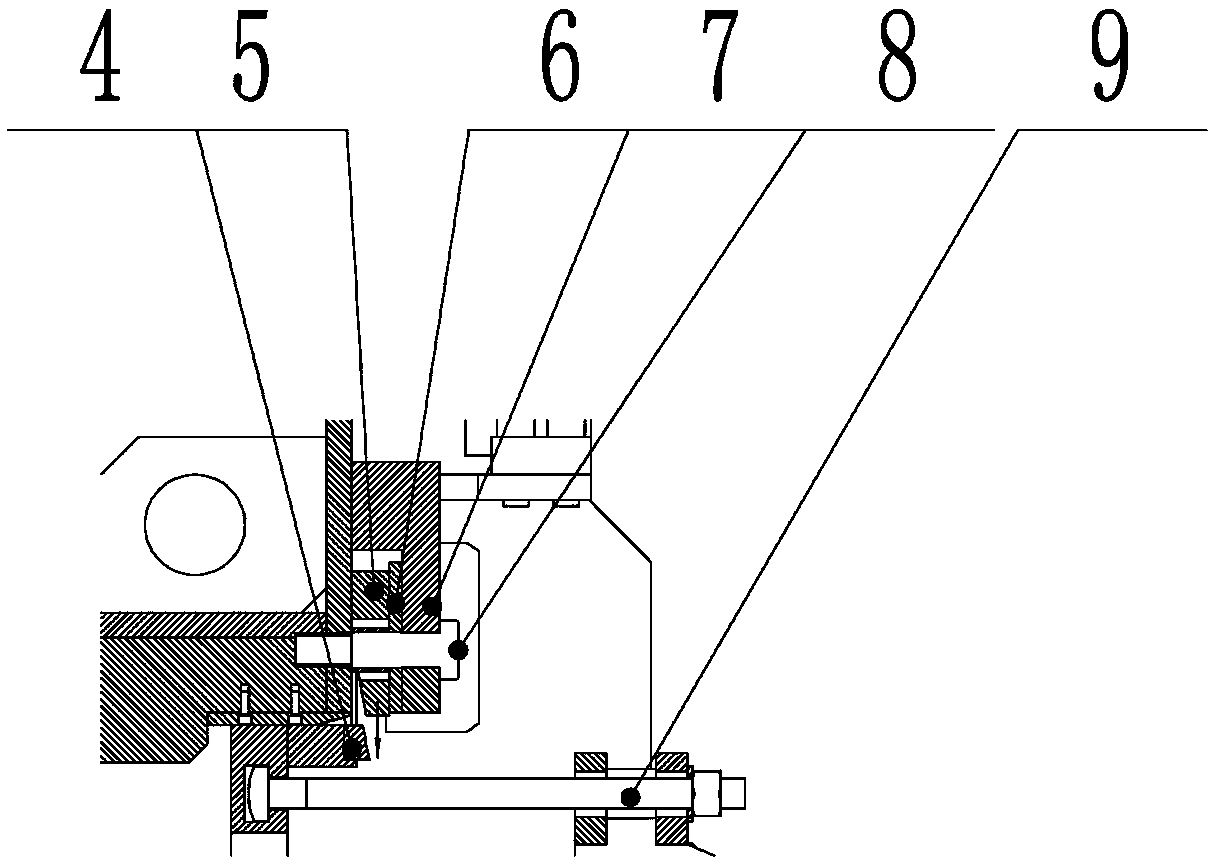

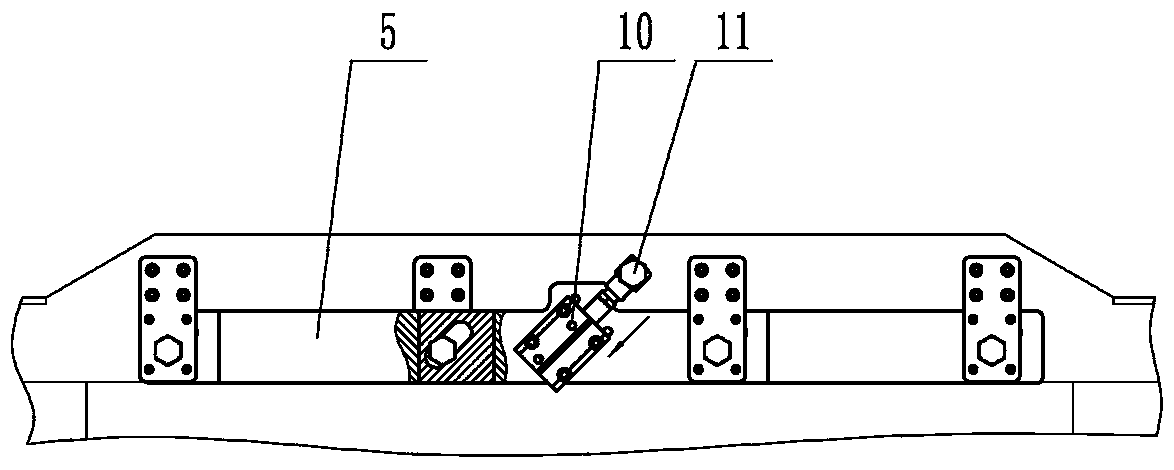

[0015] Such as figure 1 , figure 2 , Figure 3-Figure 7 Shown, the present invention has included solid formwork 1, formwork frame 2, baffle plate 3, clamping backing plate 4, clamping plate 5, backing plate 6, fixing block 7, fixing pin 8, adjusting screw rod 9. Such as figure 1 , figure 2 As shown, the clamping backing plate 4 is fixed on the mold frame 2, and the clamping plate 5 is connected to the solid plate 1 through the fixing block 7 and the fixing pin 8, wherein the clamping plate 5 and the fixing block 7 are equipped with Backing plate 6. Baffle plate 3 is installed on the formwork frame 2 by adjusting screw rod 9, and the distance can be adjusted back and forth. Such as image 3 As shown, the piston rod end of the clamping cylinder 10 is fixed on the solid plate 1 through the latch 11, and the cylinder body is connected with the clamping plate 5. When the mold frame 2 is pushed into place (the position shown in the figure), the mold clamping cylinder 9 pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com