Parallel leveling system for vehicles

A technology for vehicles and air springs, which is applied in the field of parallel leveling systems for vehicles, and can solve the problems of slowing down and not reducing back pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

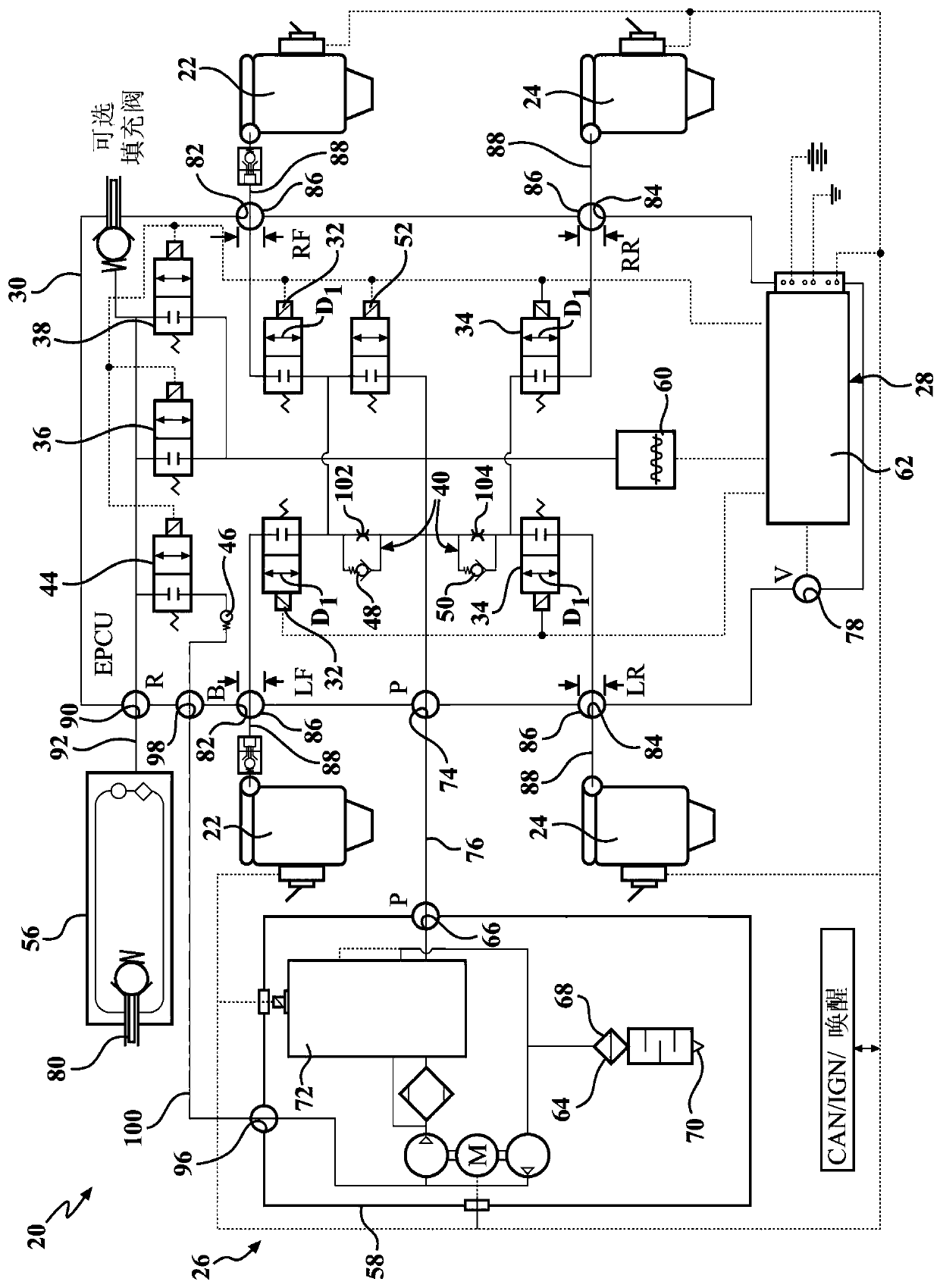

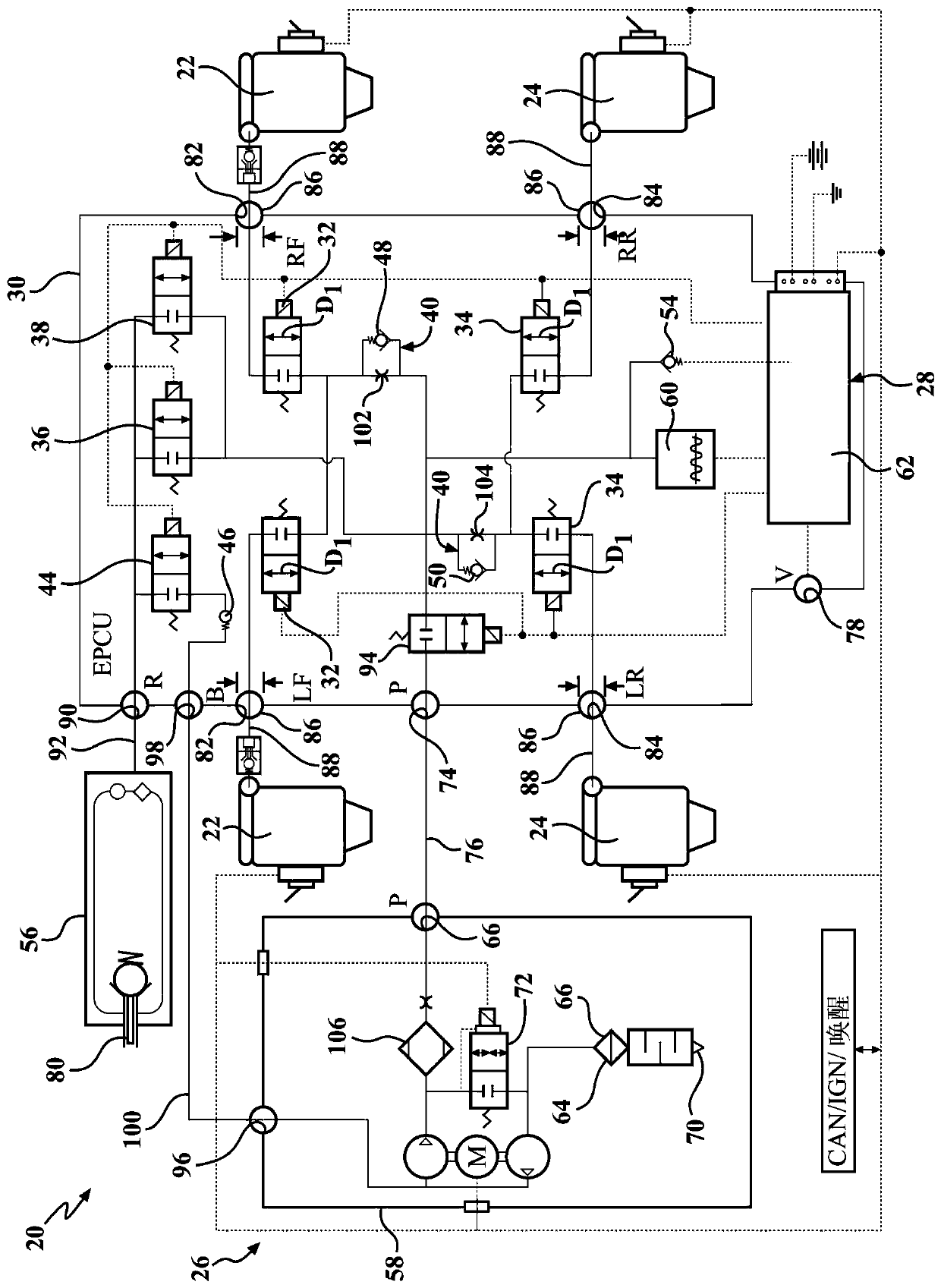

[0026] Referring to the drawings, wherein like numerals designate corresponding parts throughout the several views, in figure 1 A parallel leveling system 20 for a vehicle is shown generally in .

[0027]Parallel leveling refers to raising and lowering the vehicle pneumatically in a smooth manner without switching the air spring blocker valve. Typically, parallel leveling system 20 is implemented in a vehicle having a front end, a rear end, and a plurality of wheels (eg, four wheels) including a pair of front wheels and a pair of rear wheels. A plurality of air springs 22, 24 are connected to the vehicle. The plurality of air springs 22 , 24 includes a pair of front air springs 22 and a pair of rear air springs 24 . Front air springs 22 are spaced apart from each other and connect the vehicle to the front wheels of the vehicle for damping relative forces between the vehicle and the front wheels. Additionally, front air springs 22 raise and lower the front end of the vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com