High-tension transmission line hot-line work insulation rope winding frame

A technology for high-voltage transmission lines and live work, applied in overhead lines/cable equipment, transportation and packaging, transportation of filamentous materials, etc., can solve the problems of inability to guarantee the insulation performance of insulating ropes in good condition, easy to sweat, time-consuming and labor-intensive, etc. Achieve the effect of smooth display or storage process, guarantee personal safety, and improve safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

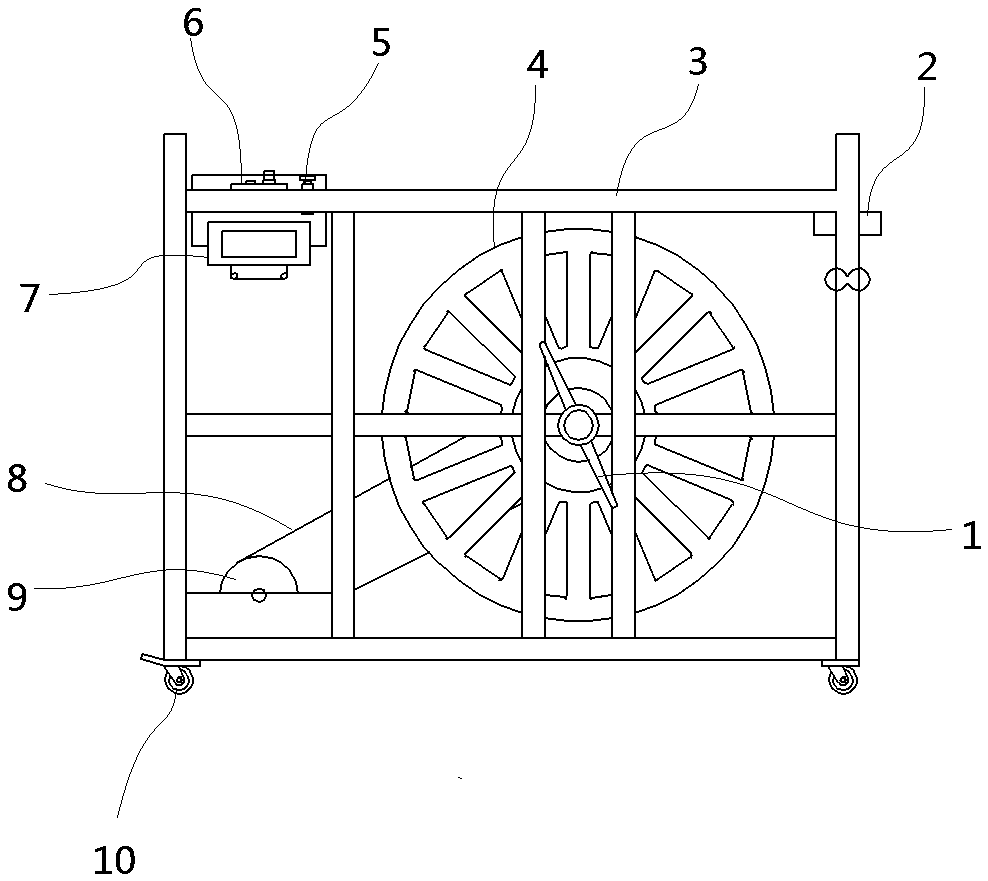

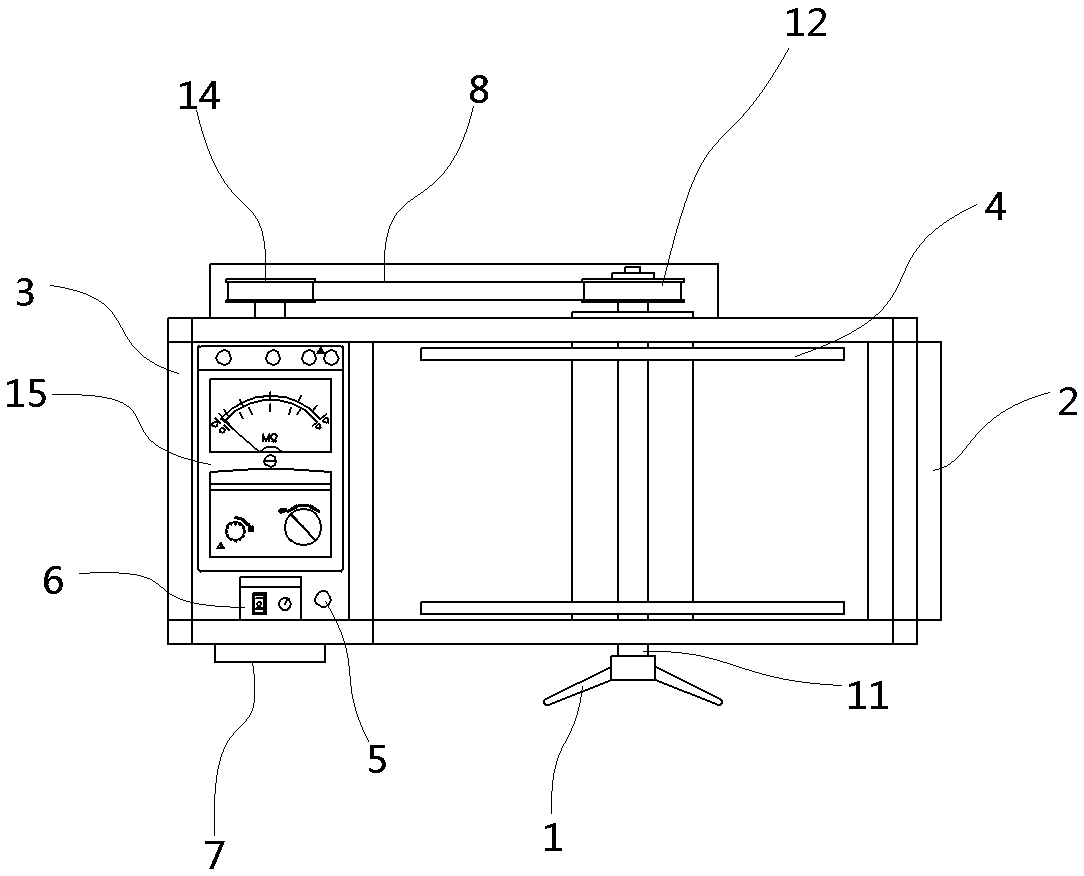

[0022] Such as figure 1 , figure 2 In the shown embodiment, a high-voltage transmission line live working insulating rope winding frame includes a frame 3 and a coil 4, and the center of the coil is provided with a rotating shaft 11, which rotates synchronously with the coil. The wire reel is arranged in the frame, the rotating shaft passes through the frame, one end of the rotating shaft is provided with a torque limiting wheel 12, the other end of the rotating shaft is provided with a threaded section, and the threaded section is provided with a nut 1 threadedly connected, and the nut connects the rotating shaft to the After the frame is positioned, the wire drum can rotate in the frame. An annular wire groove is arranged on the wire reel, and the wire groove is coaxially arranged with the wire reel, and the insulating rope is wound in the wire groove of the wire reel. The four corners of the frame bottom are provided with universal wheels 10 respectively.

[0023] A mot...

Embodiment 2

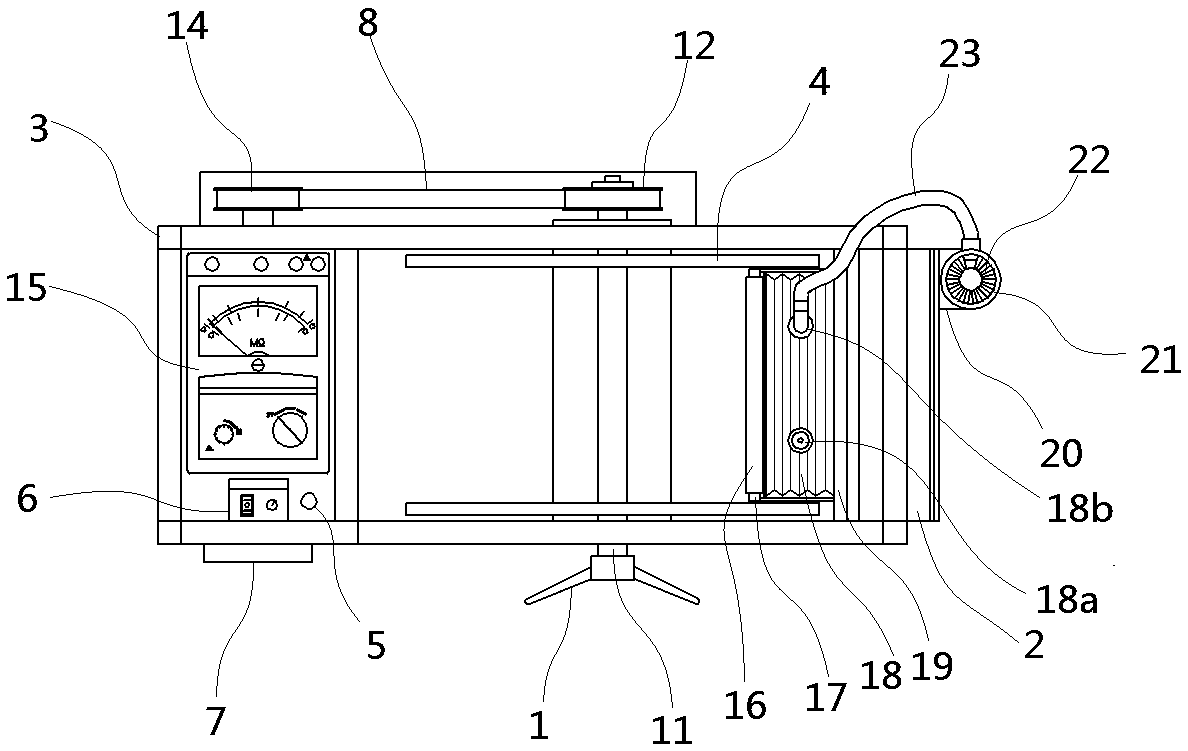

[0028] The difference between embodiment 2 and embodiment 1 is that, as image 3 As shown, the frame is provided with a slide block 20 moving along the width direction of the wire groove outside the wire outlet. The slide block is provided with an outer frame 21 for insulating ropes to pass through. The outer frame is provided with a brush 22, and the frame is provided with a There is a translation bracket 17 that moves in the wire groove and a positioning bracket 19 parallel to the bracket. The side of the translation bracket facing the wire groove is provided with a pressure roller 16 that is in contact with the insulating rope. Connected telescopic rods, an air bag 18 is provided between the translation bracket and the positioning bracket, the air bag is provided with an air intake check valve 18a and an air outlet check valve 18b, the outer frame is provided with an inwardly open air outlet, and the air outlet check valve A flexible pipe 23 is connected with the gas outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com