Automatic tiling machine for floor tiles

An automatic, brick machine technology, applied in the direction of construction, building construction, etc., can solve the problems of large structure, difficulty for workers to use, complex structure of brick tiling machine, etc., and achieve the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

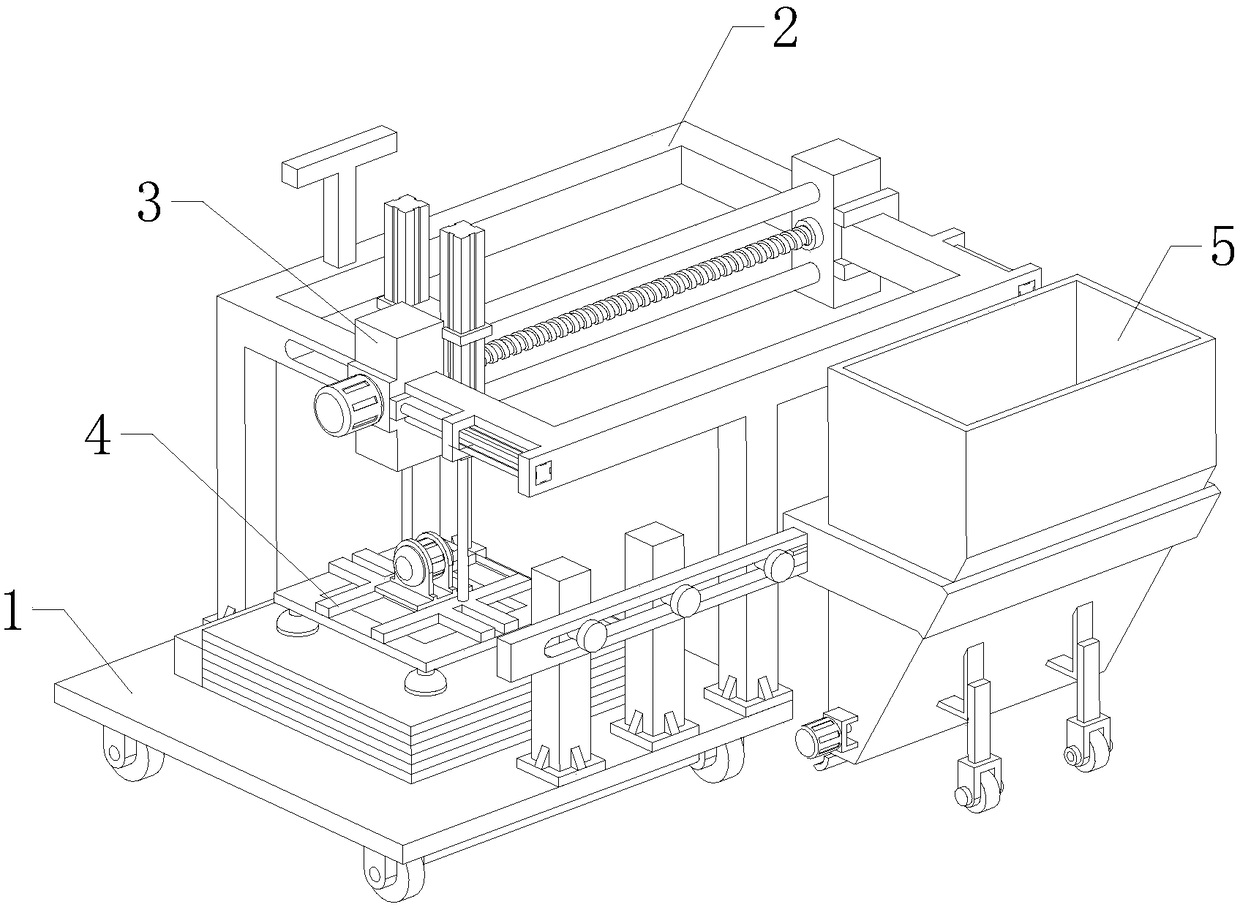

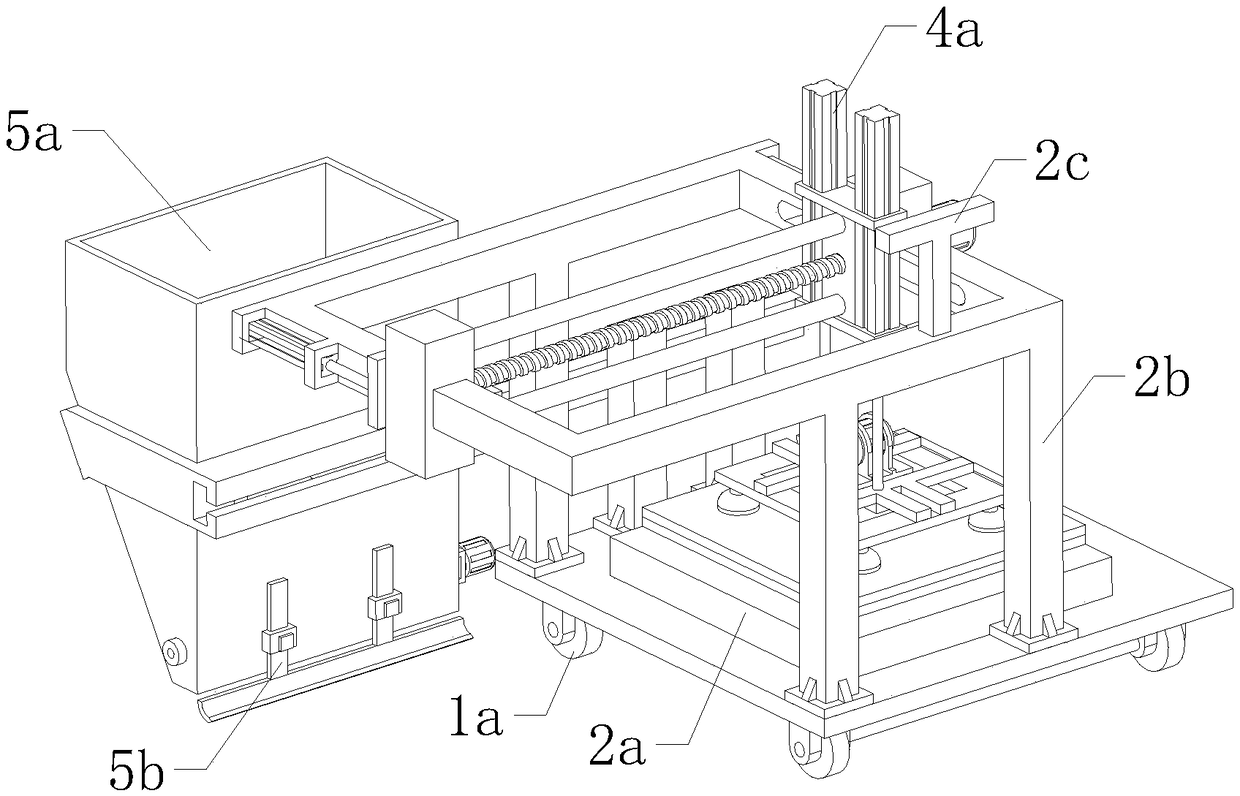

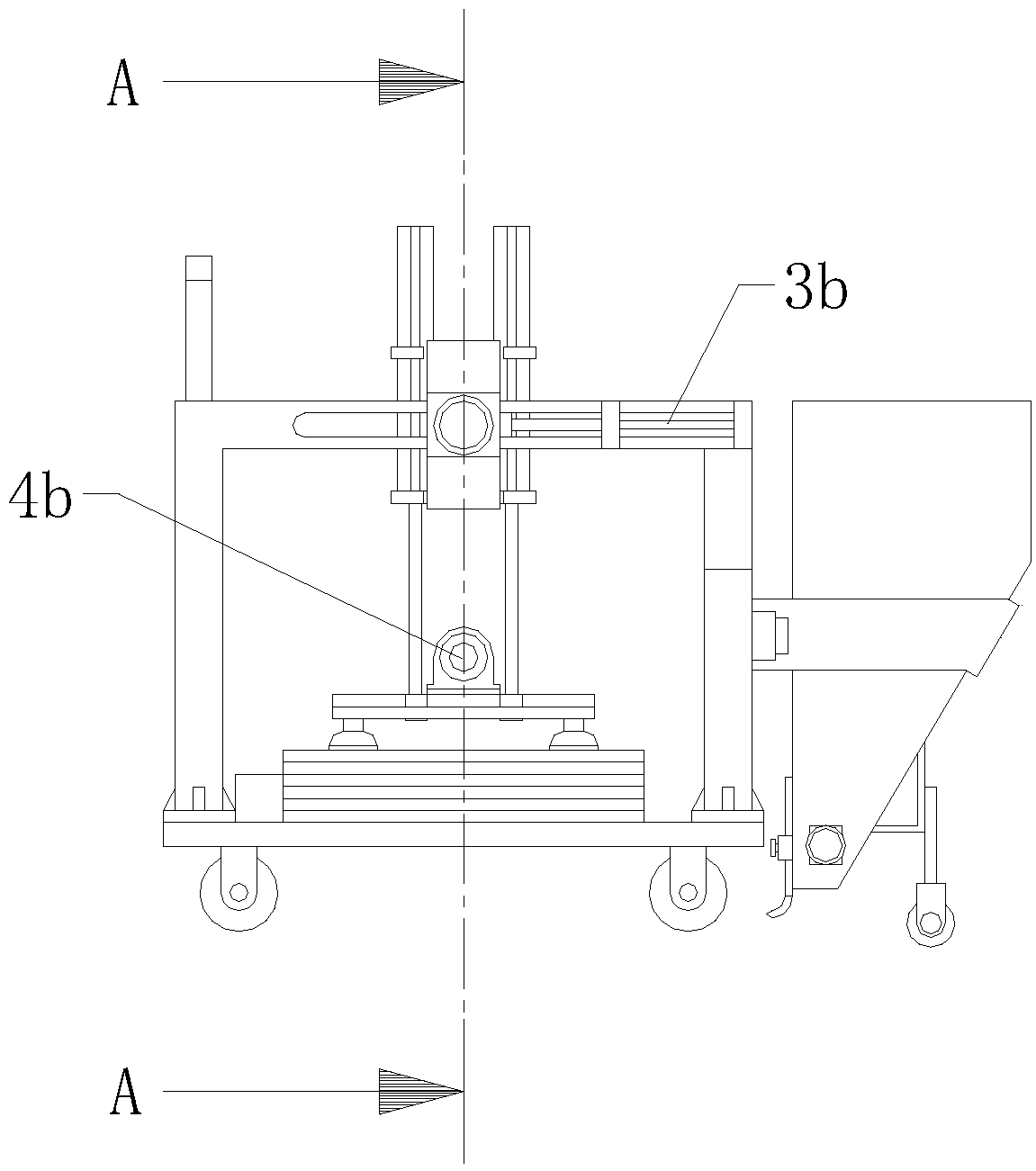

[0029] refer to Figure 1 to Figure 10 An automatic tile tiling machine for laying floor tiles is shown, including a chassis 1, a supporting device 2 arranged on the chassis 1, a moving device 3 arranged on the supporting device 2, and a tile tiling device arranged on the supporting device 2 4 and the unloading device 5 arranged on the support device 2, the bottom of the chassis 1 is provided with a number of rollers 1a to facilitate the movement of the chassis 1, the support device 2 includes a limit assembly 2a, a support assembly 2b and a hand-held assembly 2c, the support assembly 2b is fixed on the top of the chassis 1, the hand-held assembly 2c is fixed on the support assembly 2b, the limit assembly 2a is fixed on the top of the chassis 1, and the moving device 3 includes a lateral The moving assembly 3a and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com