Concentric double-pipe injection-production horizontal well physical simulation device for thermal recovery of heavy oil

A technology of heavy oil thermal recovery and double-pipe injection production, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc., can solve the problem of short steam migration distance, simplify the experimental installation steps, and improve recovery rate, improve the effect of steam injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

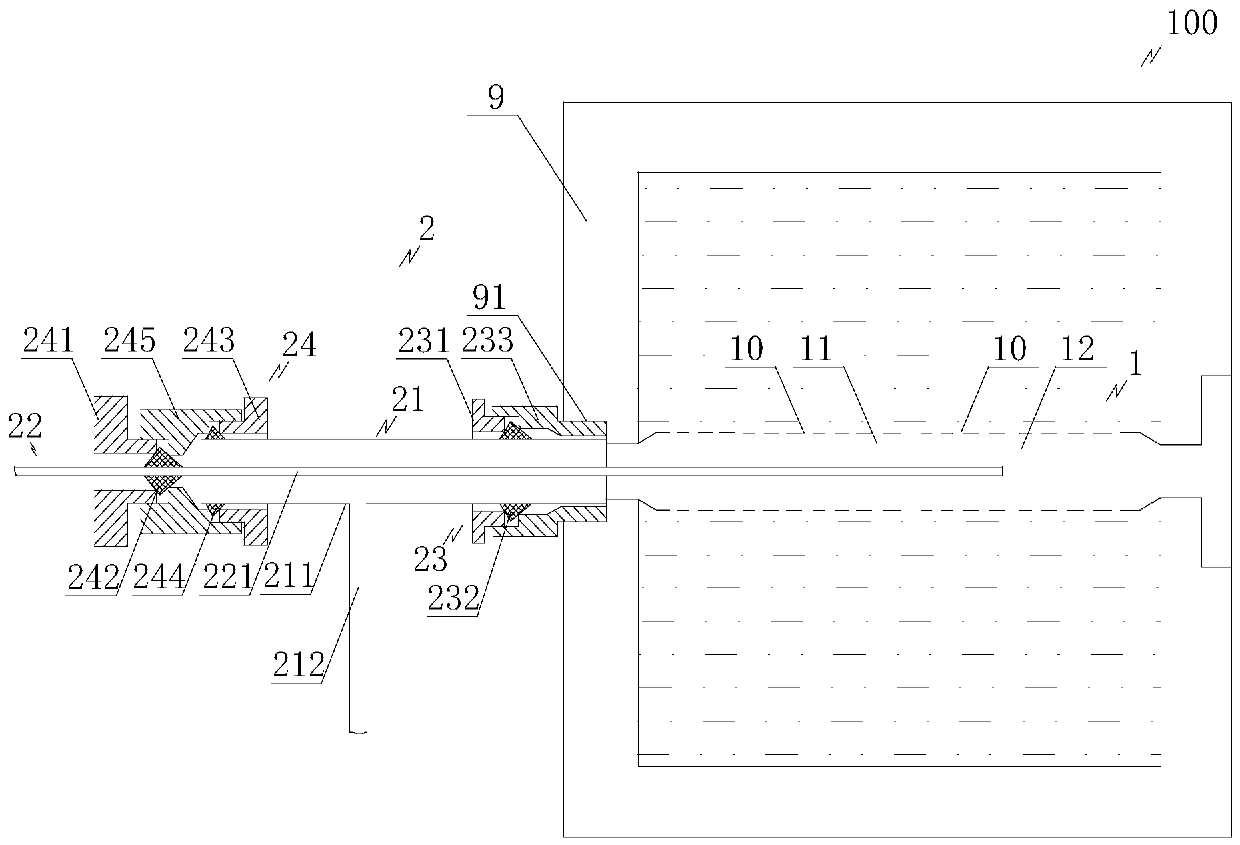

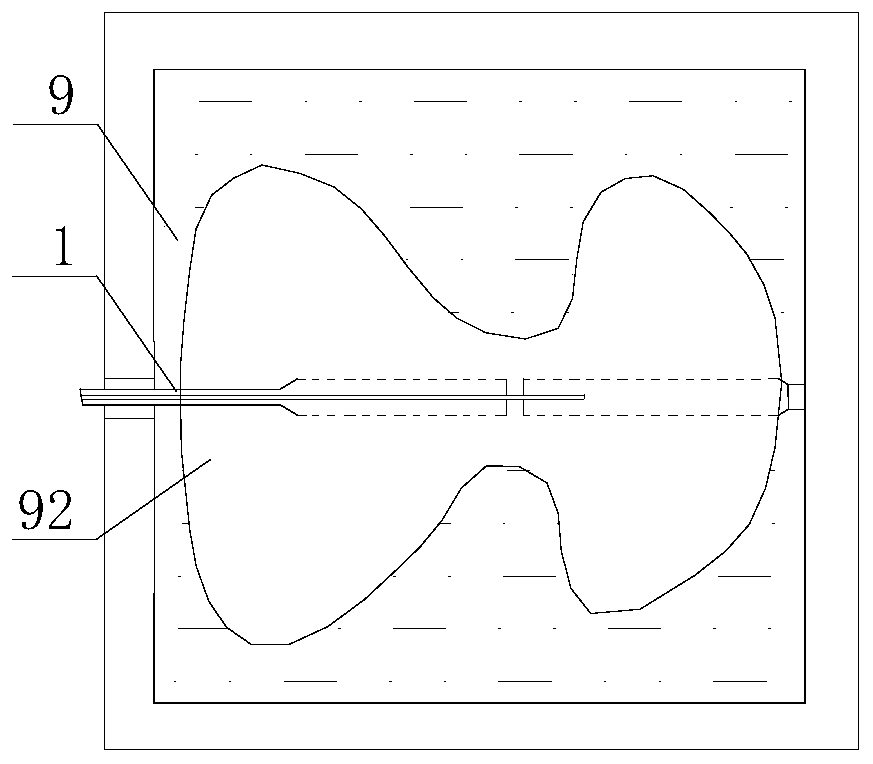

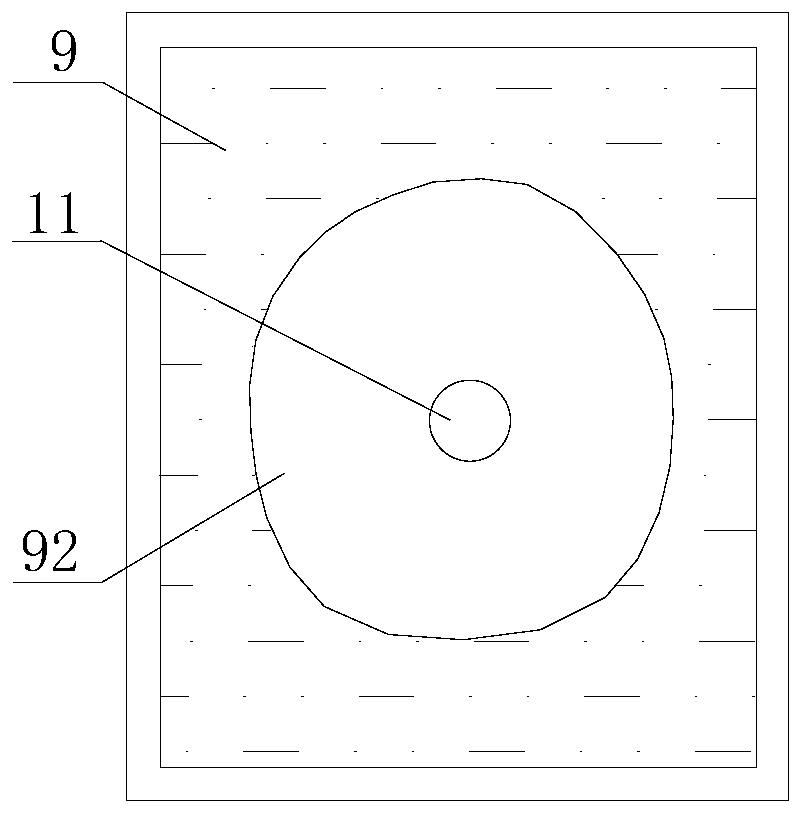

[0035] like figure 1 As shown, the present invention provides a physical simulation device 100 for concentric double-tube injection-production horizontal wells for thermal recovery of heavy oil, comprising a heavy oil reservoir model 9, and a dual horizontal well combination structure 1 is set in the heavy oil reservoir model 9, The dual-horizontal well combination structure 1 includes a first horizontal well 11 and a second horizontal well 12 which are coaxially and have equal diameters and are axially sealed and spaced. The end of the first horizontal well 11 away from the second horizontal well 12 constitutes a steam injection inlet. One end of the horizontal well 11 close to the second horizontal well 12 is sealed, and both ends of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com