Column-hanging type multifunctional heat conducting fort

A multi-functional, column-mounted technology, used in thermal storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of failure to meet national environmental protection requirements, excessive nitrogen oxide emissions, and large boiler footprint. To solve the problem of excessive nitrogen oxide emissions, reduce the generation of nitrogen oxides, and reduce the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

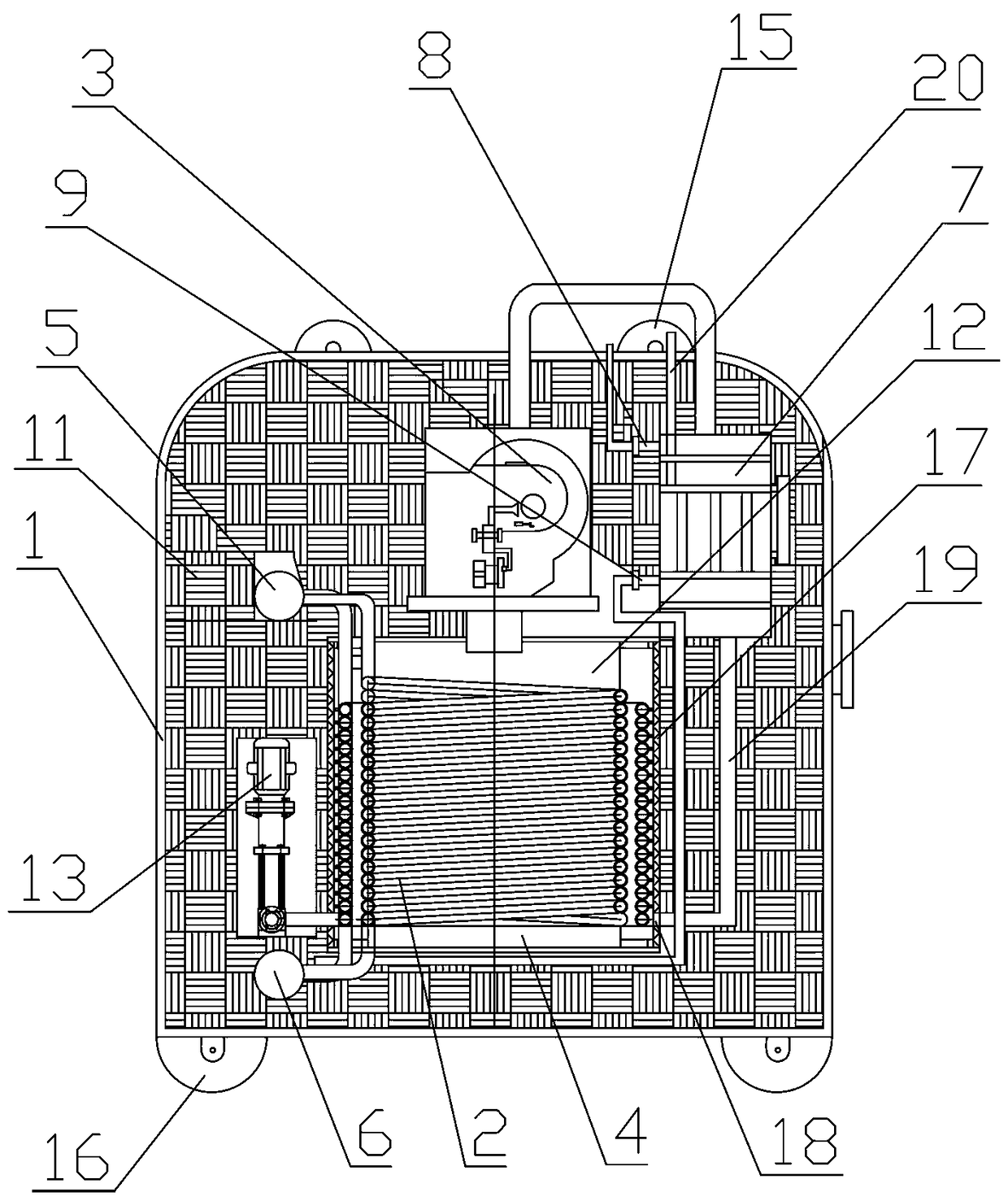

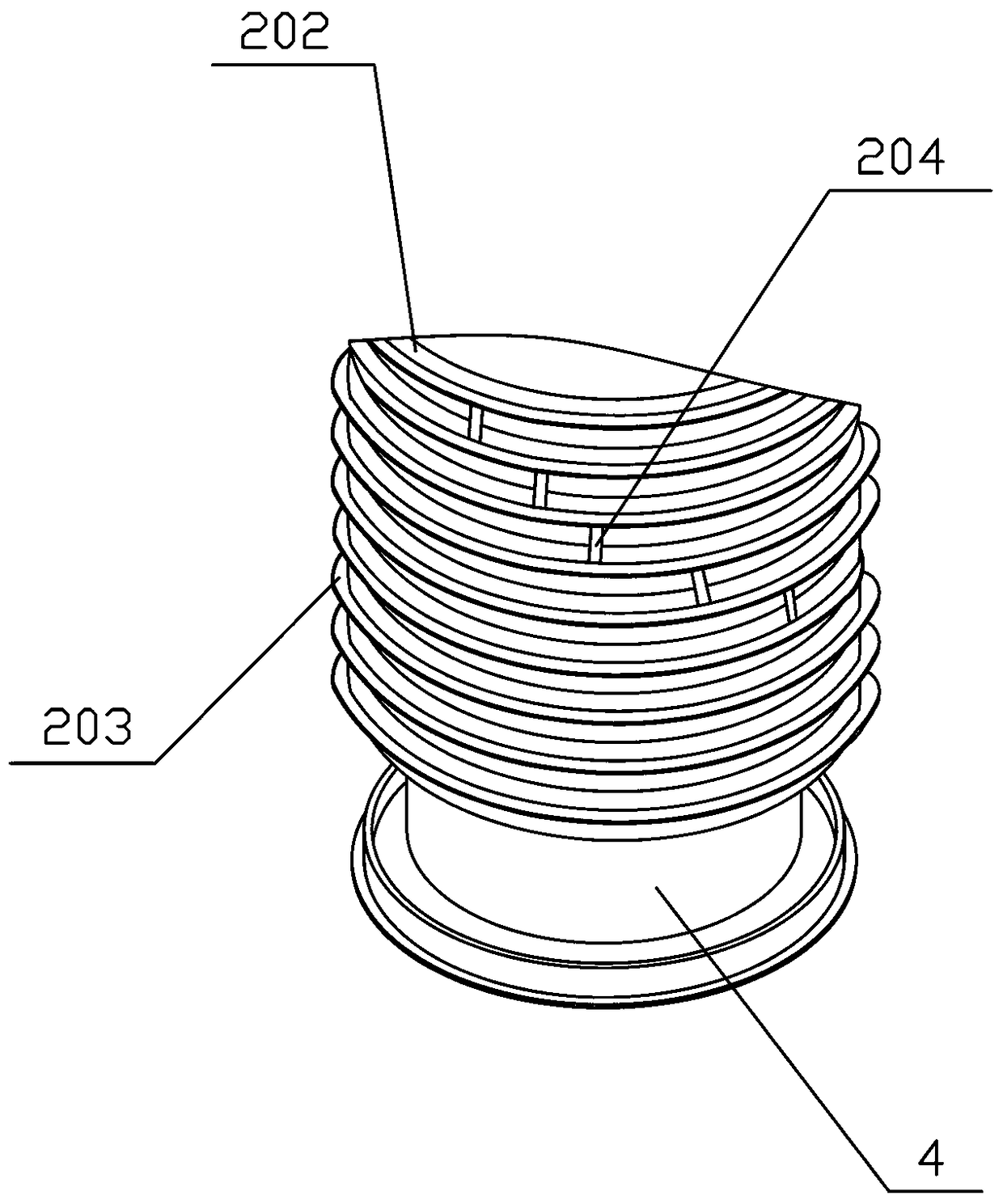

[0031] Such as Figure 1 to Figure 6 As shown, the column-mounted multifunctional heat conduction castle includes a heat conduction castle shell 1 and a burner 3 arranged in the upper middle of the inner cavity of the heat conduction castle shell 1, and a double-layer heat pipe is vertically arranged in the middle of the inner cavity of the heat conduction castle shell 1, The double-layer heat pipe is composed of an inner heat pipe 201 and an outer heat pipe 202. Both the inner heat pipe 201 and the outer heat pipe 202 are in the shape of a spiral coil, and the middle part of the inner heat pipe 201 forms a first gas channel. 21. The inner layer heat pipe 201 is fixed to the middle of the outer layer heat pipe 202 with a space between them to form the second gas passage 22, and the double layer heat pipe forms the heat conduction fortress 2. In this embodiment, the inner layer heat pipe 201 The top of the top exceeds the top of the outer heat pipe 202, so that the height of th...

Embodiment 2

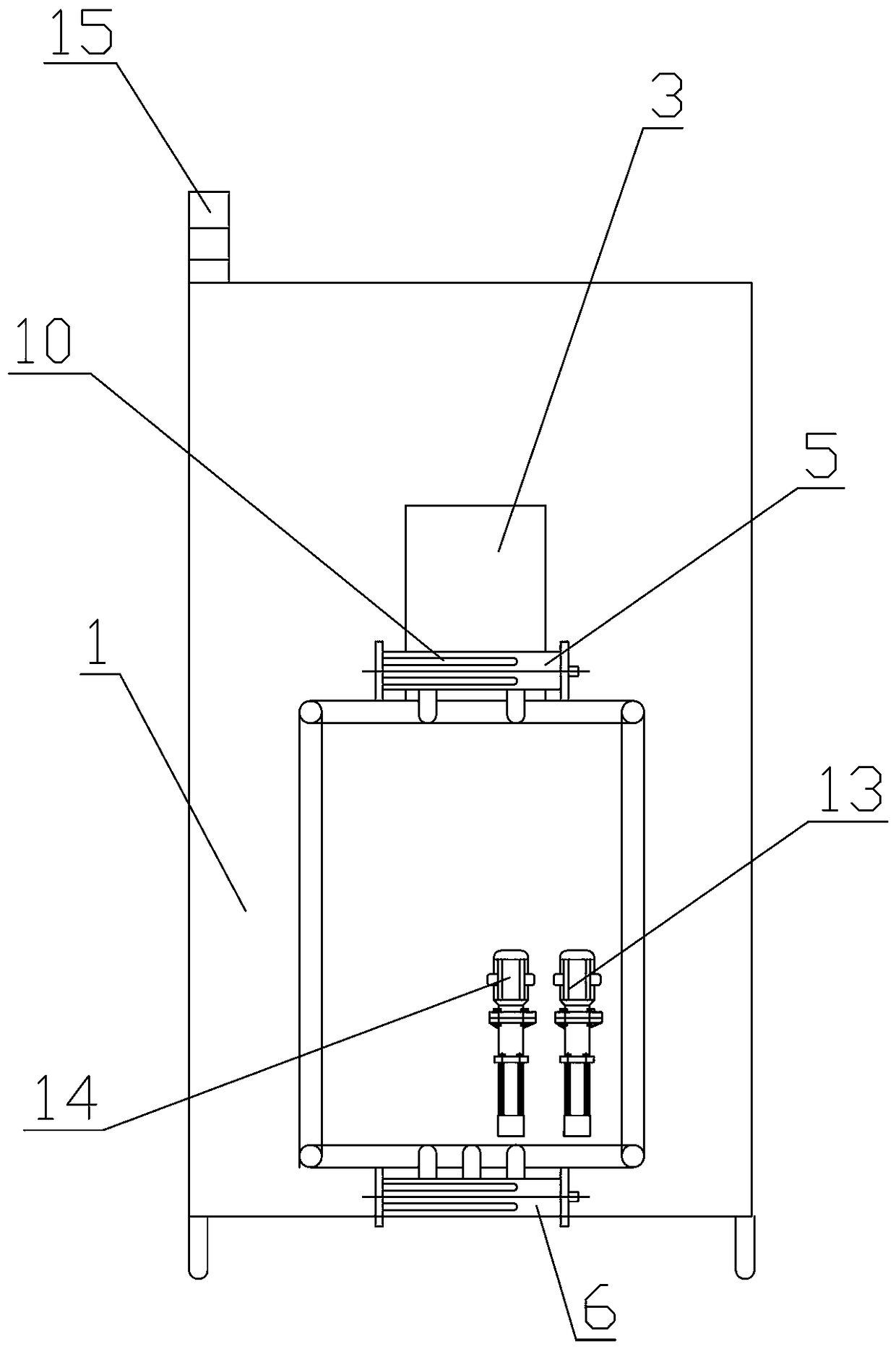

[0046] This embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is: the column-hanging multifunctional heat conduction castle, the upper header 5 and the lower header 6 are both hollow structures, and the upper header A heating element 10 is provided in the middle of the inner cavity of the tank 5 and the lower header 6. Specifically, the heating element 10 in this embodiment is an electric heating tube. When the burner 3 is damaged, the oil or water is heated through the heating element 10. Then through the outlet provided on the upper header 5, heat is provided for the user. The setting of the heating element 10 enables the present invention to achieve the purpose of interoperability of oil, gas and electricity, and realize multi-functional operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com