Power distribution box

A power distribution box and cover plate technology, applied in electrical components, substation/switch layout details, busbar/line layout, etc., can solve the problems of low space utilization, long maintenance time, increased research and development, etc., and achieve high space utilization. , The installation and maintenance are simple and reliable, and the product volume is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described in detail in conjunction with the summary of the invention and the accompanying drawings.

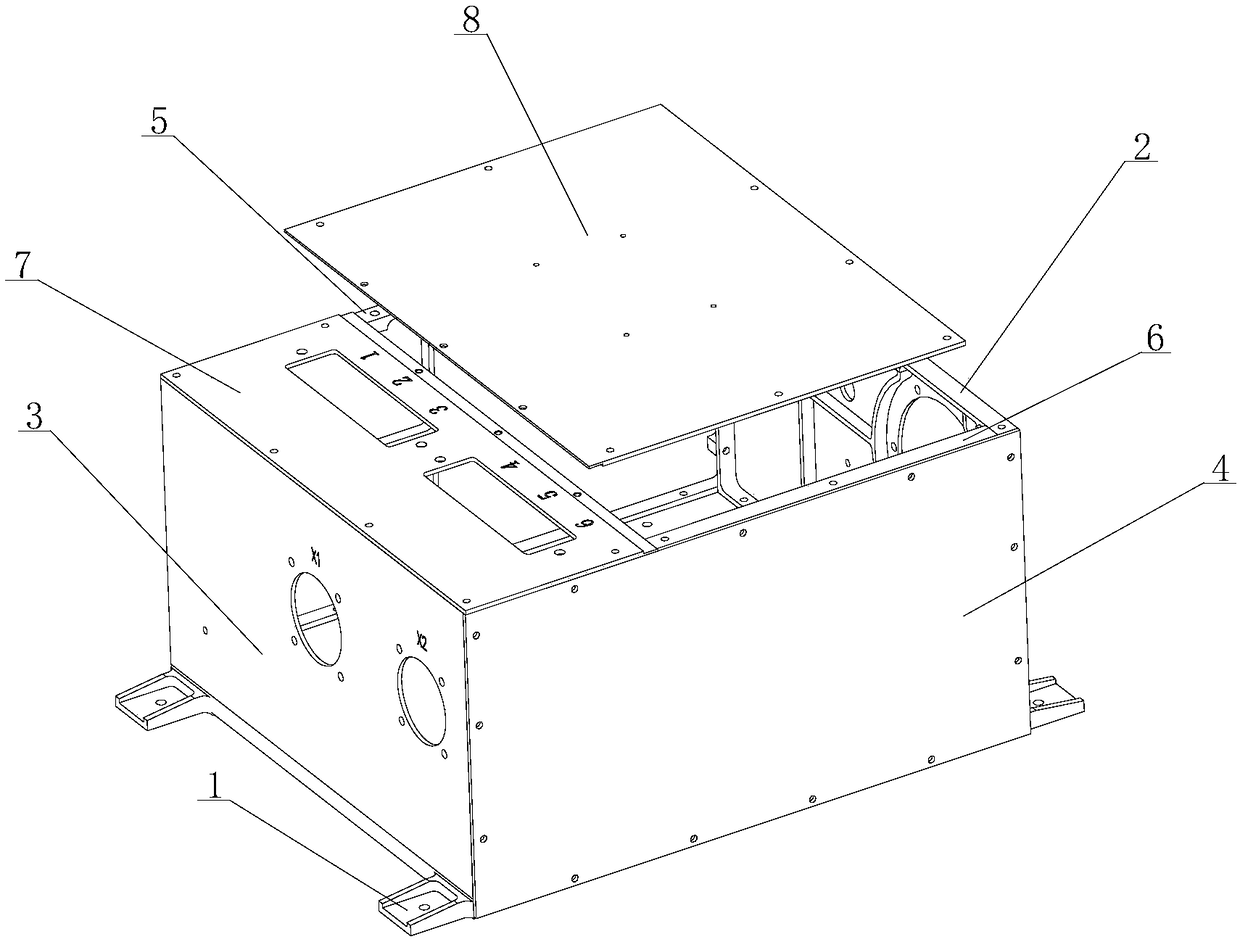

[0023] A power distribution box, including a base plate 1 at the bottom, a front panel 2, a rear side plate 3, a left side plate 4, and a right side plate 5 are arranged on the bottom plate 1, and a cover plate I7 and a cover plate II8 are arranged on the top, forming a Closed box shape, each board is detachably connected by screws, and each board is provided with a number of mounting holes. Four corners of the bottom plate 1 are provided with mounting ears.

[0024] The terminal assembly is installed on the cover plate 1 .

[0025] The outer surfaces of the bottom plate 1, the front panel 2, the rear side plate 3, the left side plate 4, the right side plate 5, the cover plate I7, and the cover plate II8 are all provided with reinforcing ribs.

[0026] The front panel 2 is provided with a mounting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com