Rice-flavored wine flavor improving and aging promoting method

A rice-flavored and flavored technology, which is applied in the field of liquor brewing, can solve problems such as chaffy smell and burnt bitterness, floc precipitation, loss of light and turbidity, etc., and achieve the effects of promoting production, easy operation, and promoting aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A production method for improving the flavor of rice-flavored liquor and promoting its aging, comprising the following steps:

[0029] Seal 100 tons of 23-degree rice wine in a stainless steel tank with heat-insulating material on the outer layer, add 80 kg of 20 angstrom activated carbon powder, and feed clean compressed air for 30 minutes at the same time; To 2 ℃, maintain 12h.

[0030] The temperature was lowered to 1°C by the refrigerating unit again, and at the same time, clean compressed air was introduced for 30 minutes, and the maintenance time was 48 hours.

[0031] Clean compressed air was passed again for 30 minutes, and the temperature was maintained at 1° C. for 5 days.

[0032] Use a diatomaceous earth filter to filter the liquor at 1°C until it becomes clear and translucent, then pass through clean compressed air for 30 minutes, and return the liquor to normal temperature, seal and age for 5 days to obtain the processed liquor.

Embodiment 2

[0034] A production method for improving the flavor of rice-flavored liquor and promoting its aging, comprising the following steps:

[0035] Seal 100 tons of 40-degree rice wine in a stainless steel tank with heat-insulating material on the outer layer, add 30 kg of 14 angm activated carbon powder, and feed clean compressed air for 40 minutes at the same time; To 4 ℃, maintain 12h.

[0036] The temperature was lowered to -2°C by the refrigerating unit again, and at the same time, clean compressed air was introduced for 45 minutes, and the maintenance time was 24 hours.

[0037] Clean compressed air was passed again for 40 minutes, and the temperature was maintained at -2°C for 4 days.

[0038] Use a diatomaceous earth filter to filter the wine at -2°C until it is clear and translucent, then pass it through clean compressed air for 45 minutes, and return the wine to normal temperature, seal and age for 7 days to obtain the processed wine.

Embodiment 3

[0040] A production method for improving the flavor of rice-flavored liquor and promoting its aging, comprising the following steps:

[0041] Seal 100 tons of 52-degree rice wine in a stainless steel tank with heat-insulating material on the outer layer, add 40 kg of 18 angstrom activated carbon powder, and feed clean compressed air for 45 minutes at the same time; To 3 ℃, maintain 12h.

[0042] The temperature was lowered to -8°C by the refrigerating unit again, and at the same time, clean compressed air was introduced for 40 minutes, and the maintenance time was 36 hours.

[0043] Clean compressed air was passed again for 45 minutes, and the temperature at -8°C was maintained for 2 days.

[0044] Use a diatomaceous earth filter to filter the wine at -8°C until it is clear and translucent, then pass in clean compressed air for 40 minutes, and return the wine to normal temperature, seal and age for 10 days to obtain the processed wine.

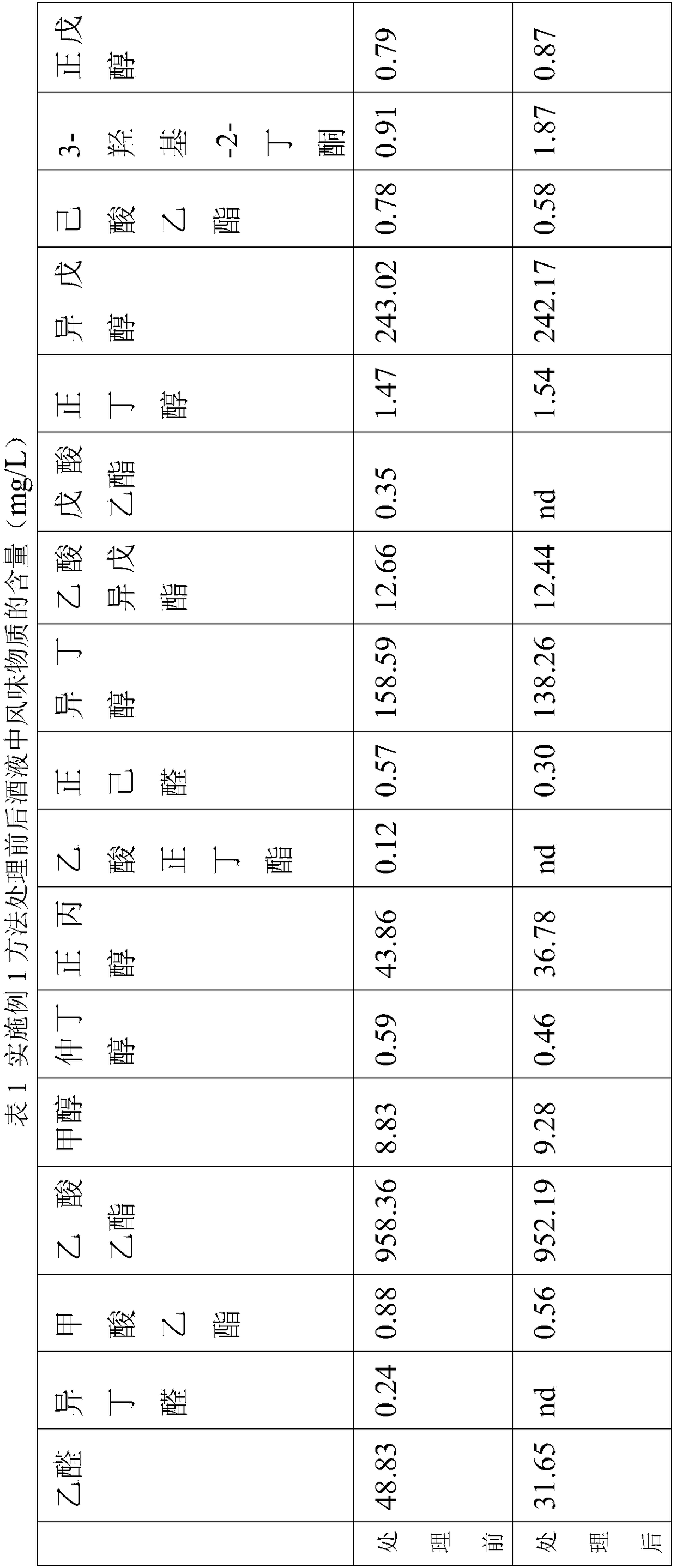

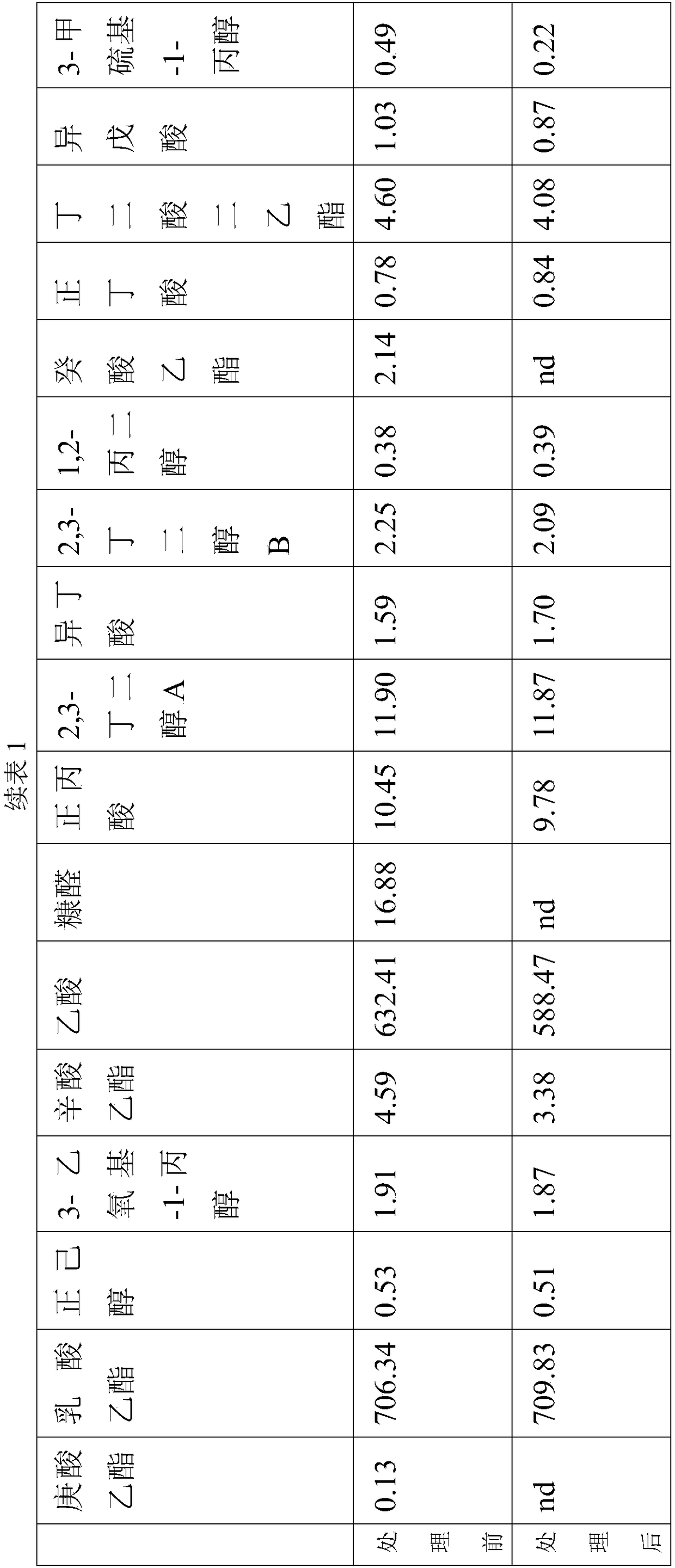

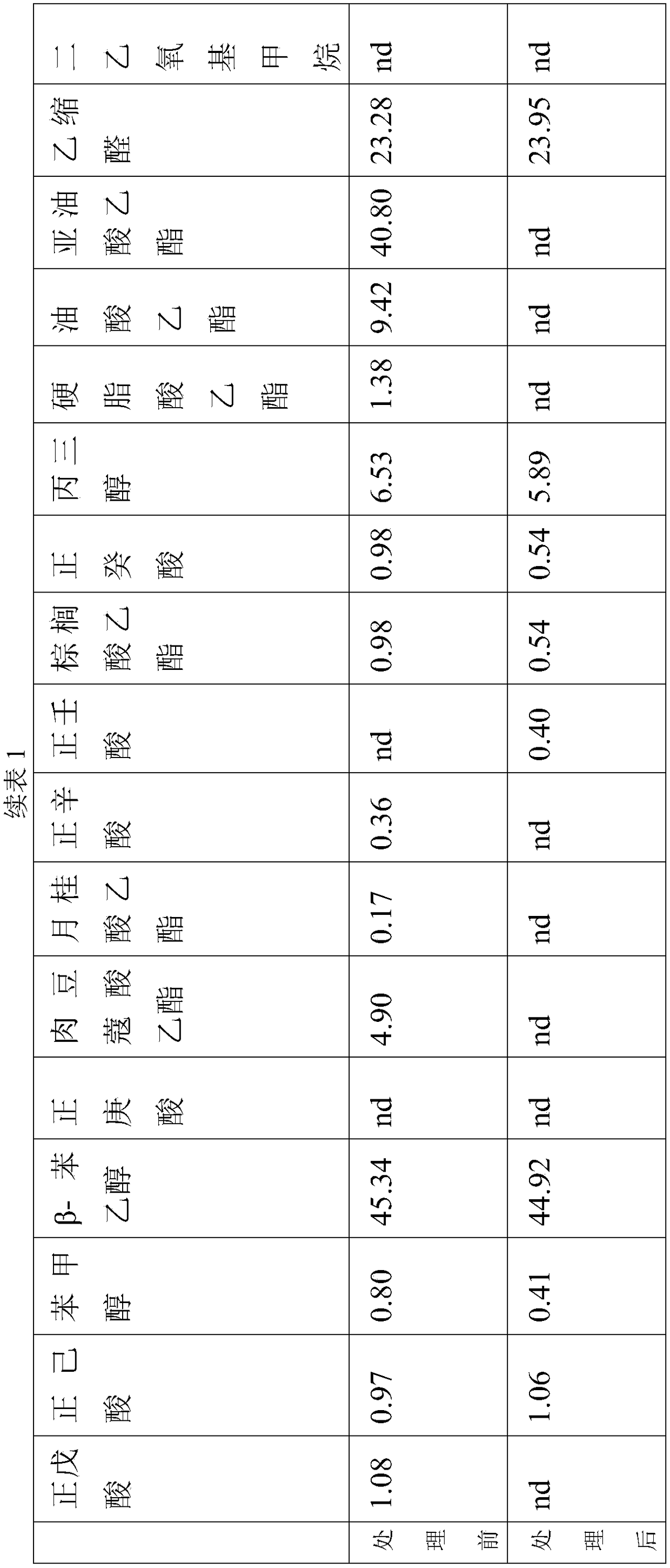

[0045]See Table 1-3 for the content c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com