Railway vehicle bogie and railway vehicle provided with the same

A railway vehicle and bogie technology, which is applied in the field of railway vehicle bogies, can solve the problem of difficult recovery of the wheel and axle, and achieve the effects of reducing lateral pressure and suppressing the change of wheel load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

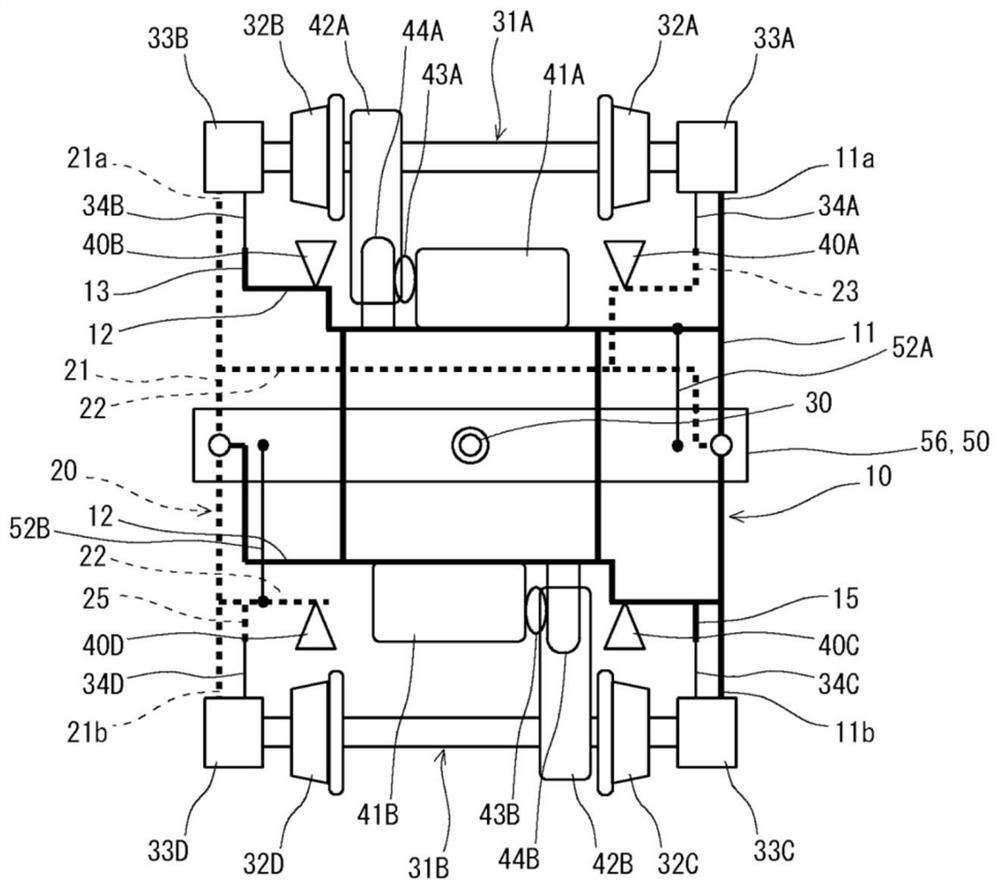

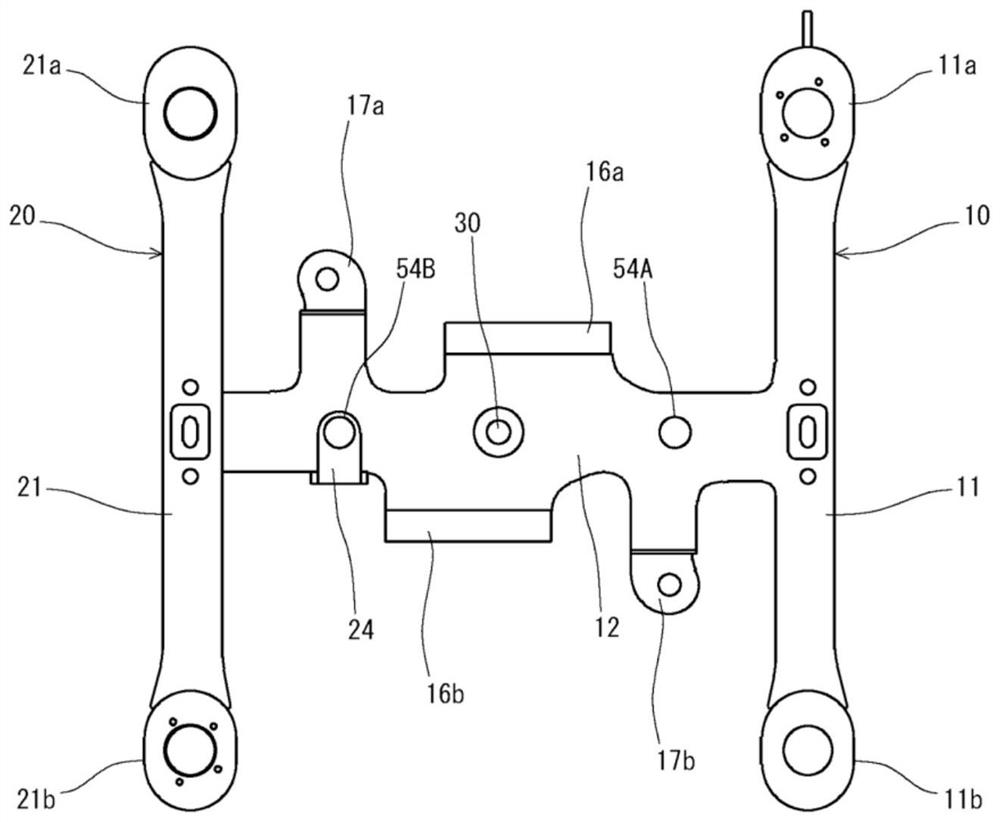

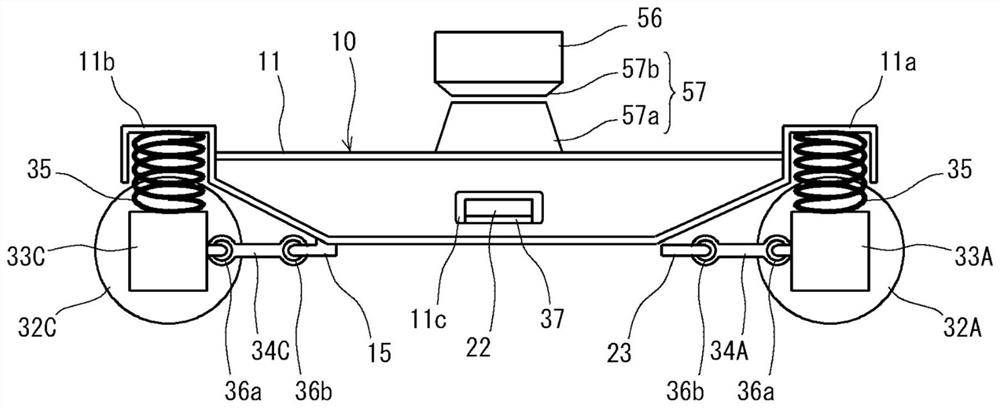

Method used

Image

Examples

Embodiment

[0087] In order to confirm the effects of the present invention, numerical simulation analysis was carried out. Specifically, various models of vehicles including one vehicle body and two steerable bogies were produced, and the conditions of traveling on a curved path were simulated by numerical analysis using the models. As the curved path, a curved path including five sections (A: entrance straight line section, B: entrance transitional curve section, C: stable curve section, D: exit transitional curve section, and E: exit straight line section) was employed. The radius of curvature of the stable curve section C is set to 200 m (curvature: 0.005). The main conditions of the model are shown in Table 1 below.

[0088] [Table 1]

[0089] distinguish Bolster support Connection of bolster to bogie frame Example Center bearing part (1 place) Shaft and hole (including rubber bushing) Past example side bearing (two places) heart plate Comparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com