A vibrating liquid crystal screen dismantling tool structure

A liquid crystal screen and vibrating technology, which is applied in the field of liquid crystal screen dismantling tool structure, can solve the problems of glass plate damage due to force, high scrap rate, high price, etc., achieve the goals of reducing lateral pressure, preventing damage, and improving dismantling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

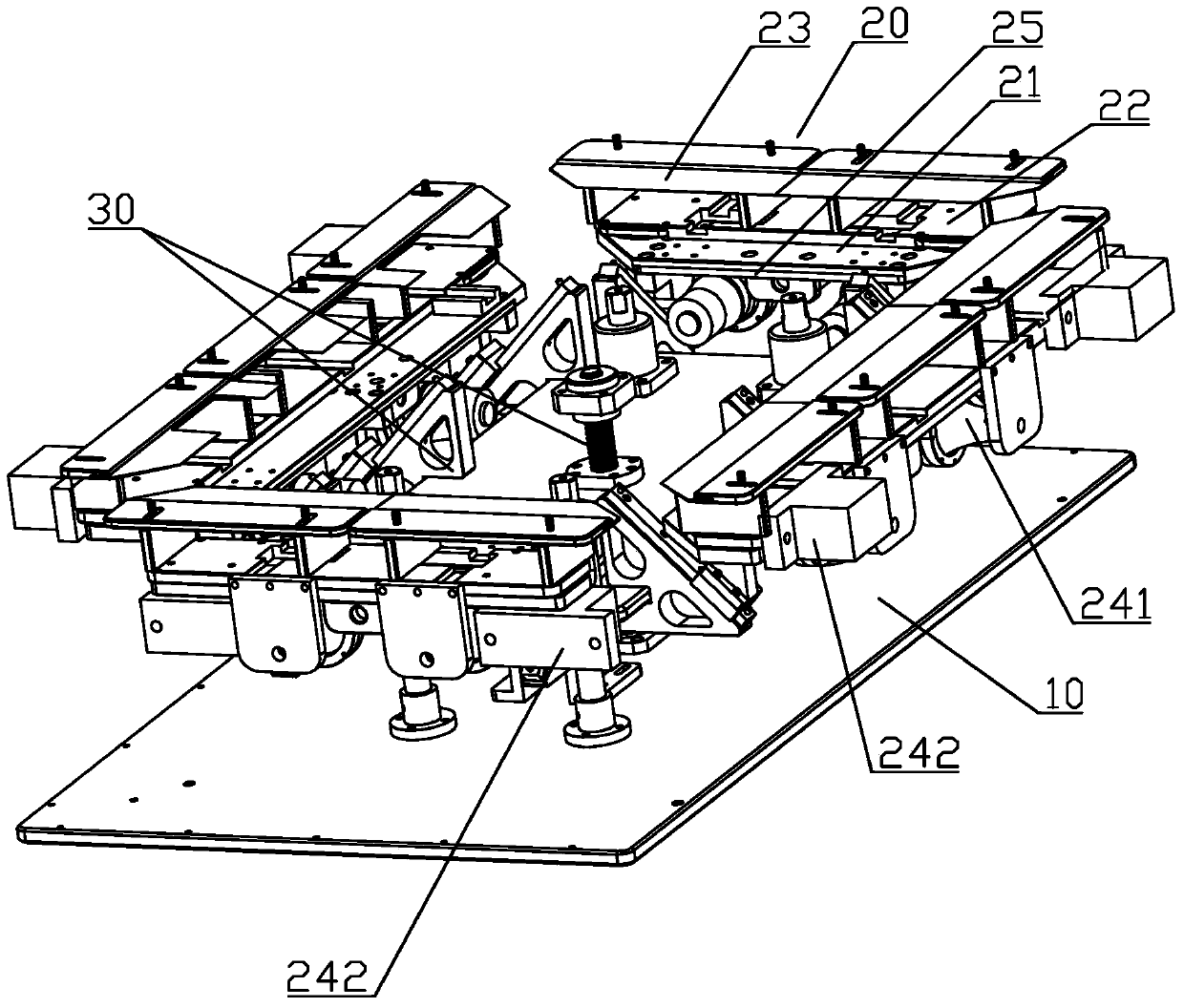

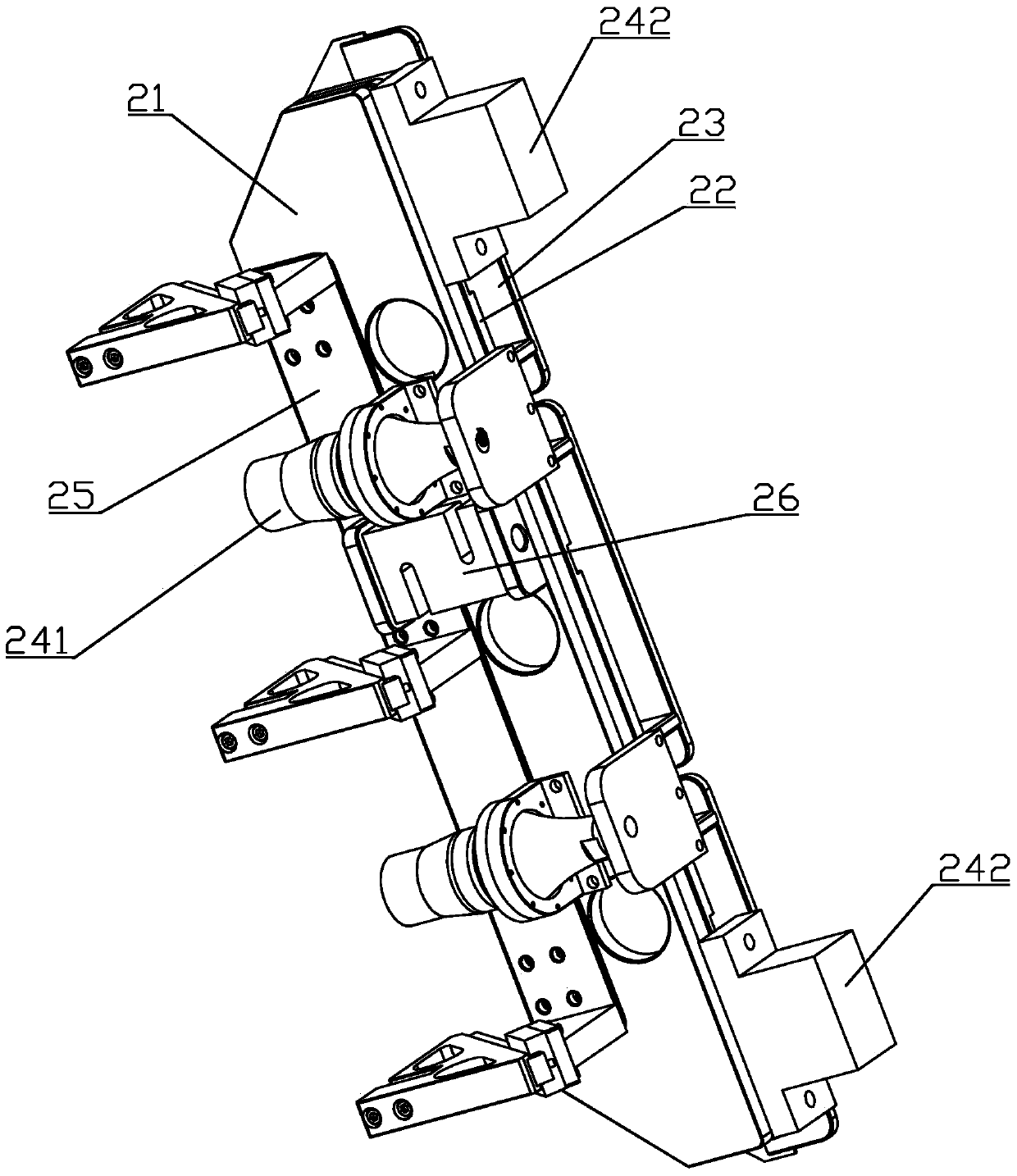

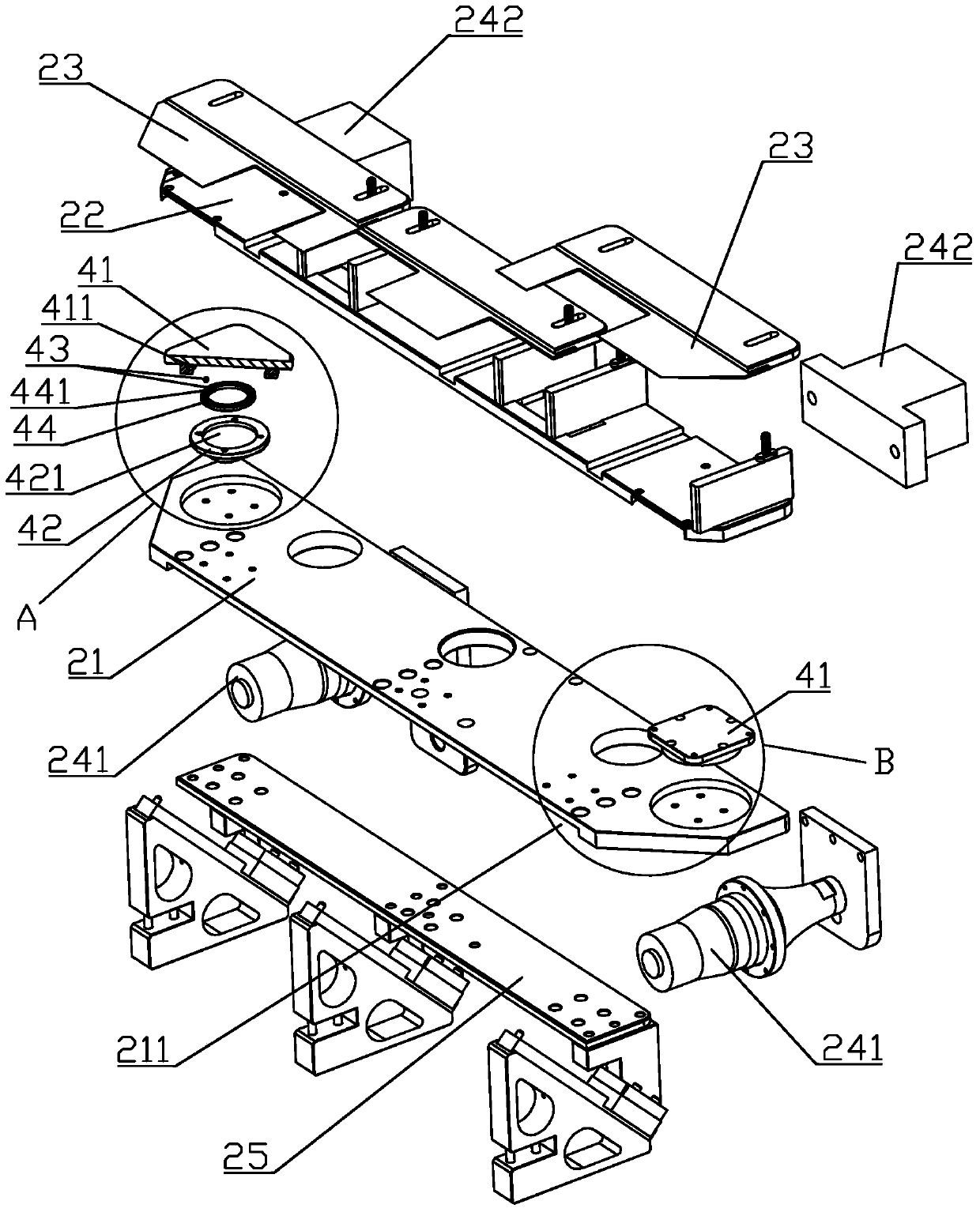

[0022] refer to Figure 1 to Figure 7 , a vibrating liquid crystal screen dismantling cutter structure, comprising a frame 10, at least one blade assembly 20 slidably arranged on the frame 10 and a driving device 30 for driving the blade assembly 20 to work forward, the blade assembly 20 includes A base 21, a blade holder 22 slidably arranged on the base 21 and at least one dismantling blade 23 arranged on the blade holder 22, the blade assembly 20 is provided with at least one vibrating device, which is used to drive the blade The seat 22 makes it vibrate back and forth relative to the base 21, so that the dismantling blade 23 on the blade seat 22 can vibrate to grind and cut the colloid, so that the dismantling blade 23 is easier to cut the colloid, improves the dismantling efficiency, and can effectively Reduce the lateral pressure on the glass plate and prevent the glass plate from being damaged due to excessive force. The dismantling blade 23 in this embodiment is in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com