Optical resonator, method of manufacturing the optical resonator and applications thereof

An optical resonator, resonator technology, applied in the structure/shape of optical resonator, optics, lasers, etc., to achieve the effect of promoting compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

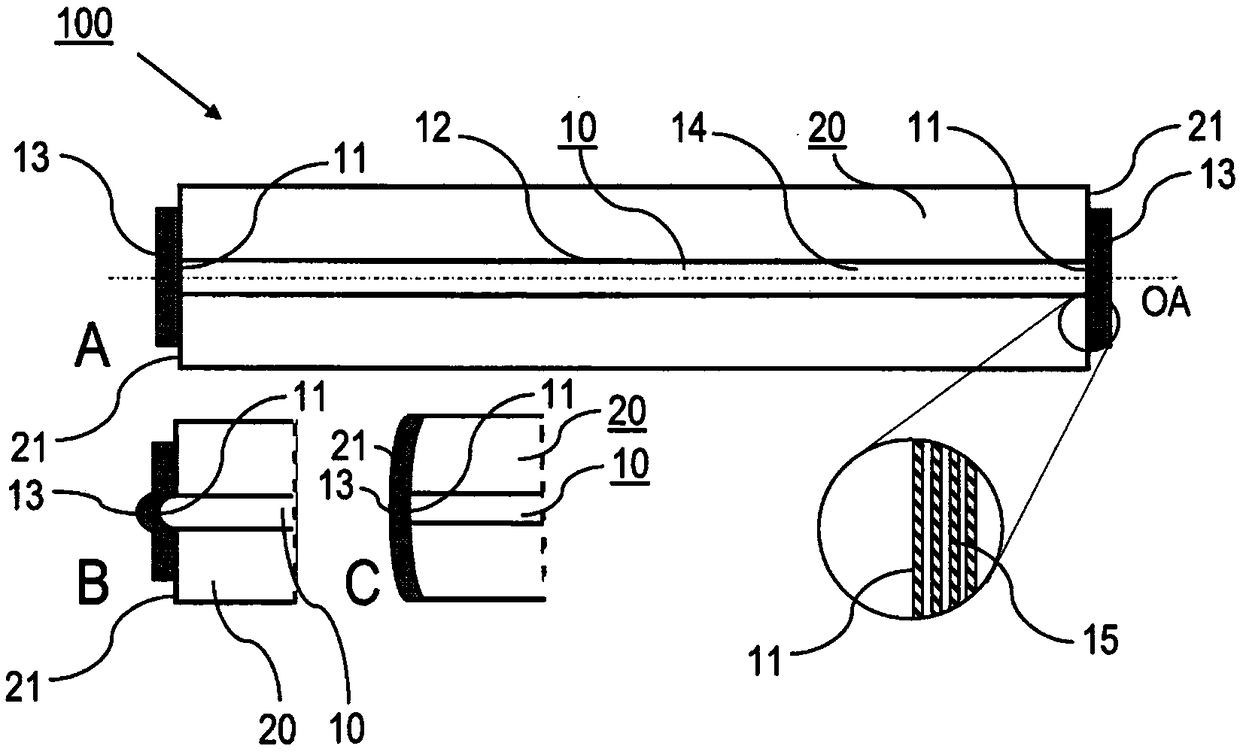

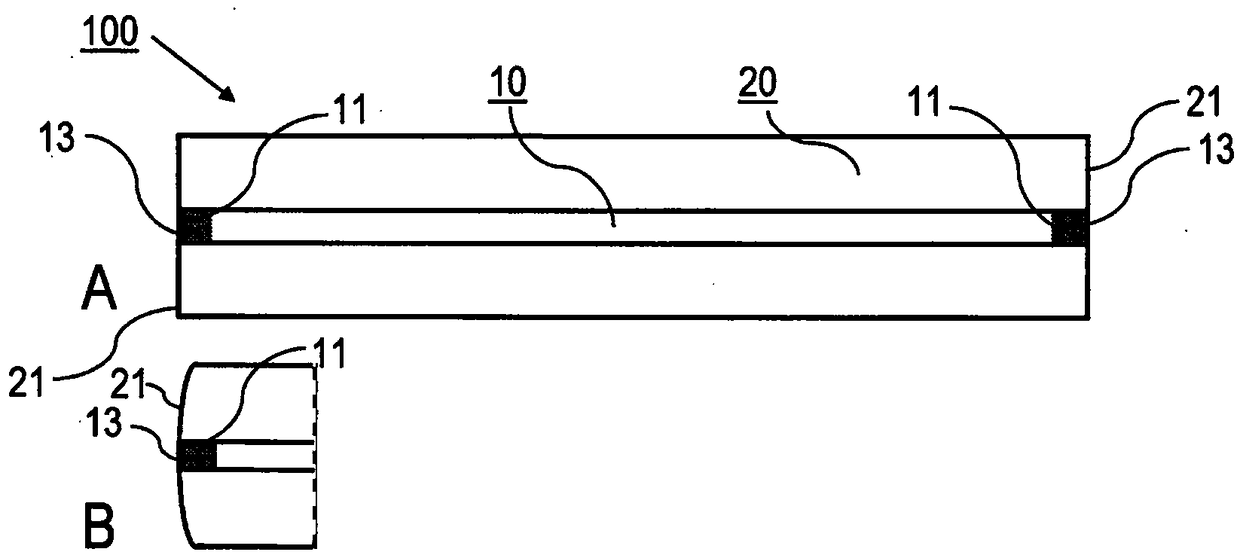

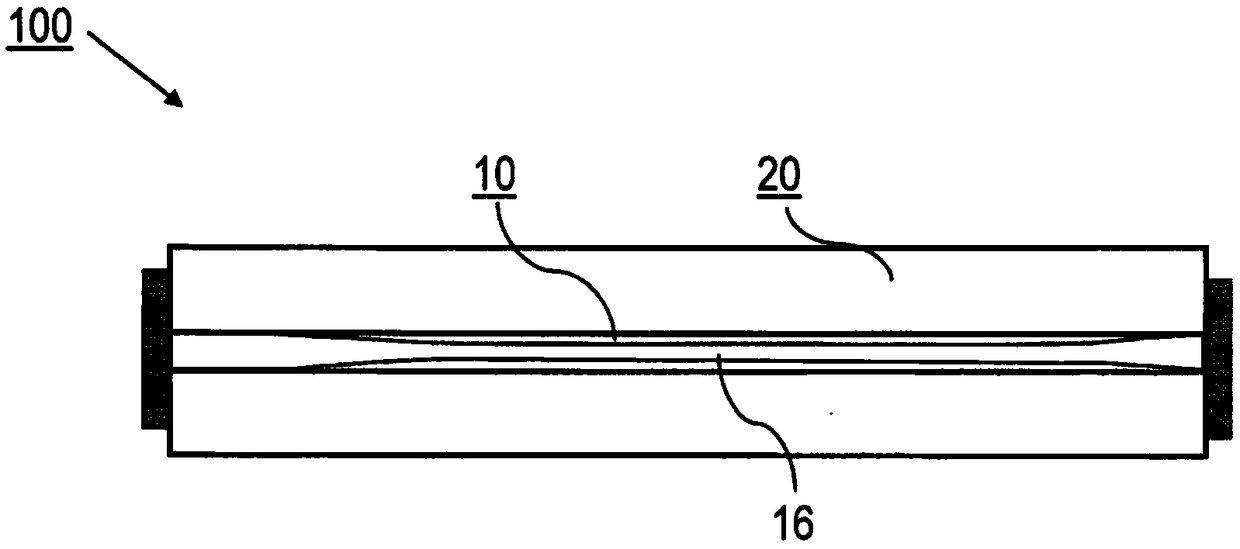

[0055]Embodiments of the invention are described below with reference to the example of an optical resonator comprising an optical fiber as an optical waveguide. It is emphasized that the invention is not limited to the use of optical fibers, but may be used for other types of optical waveguides, such as solid rods of (potentially doped) glass, crystals or semiconductor materials. Furthermore, the use of single-mode fibers as optical waveguides is specifically mentioned. Implementation of the invention is not limited to this example, but is possible for other types of optical fibers as described above.

[0056] The figures show an enlarged cross-sectional view of an optical resonator, wherein details of the resonator are schematically shown for illustrative purposes. In practice, especially the thickness of the resonator mirror and the diameter of the optical waveguide are much smaller compared to the dimensions of the ferrule.

[0057] Figure 1-5 An embodiment of an optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com