An energy-saving commercial gas steamer

A steam box and gas technology, applied in the field of kitchen utensils, can solve the problems of large heat loss, waste of fuel, waste of energy, etc., and achieve the effect of improving energy utilization and avoiding heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

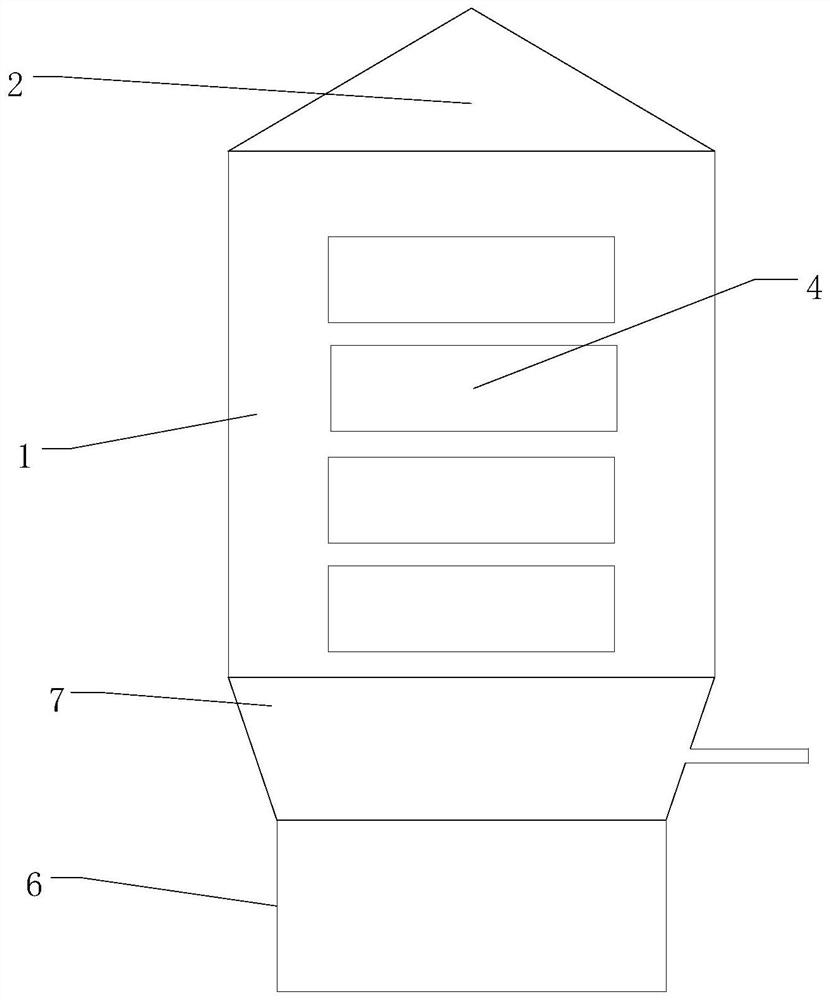

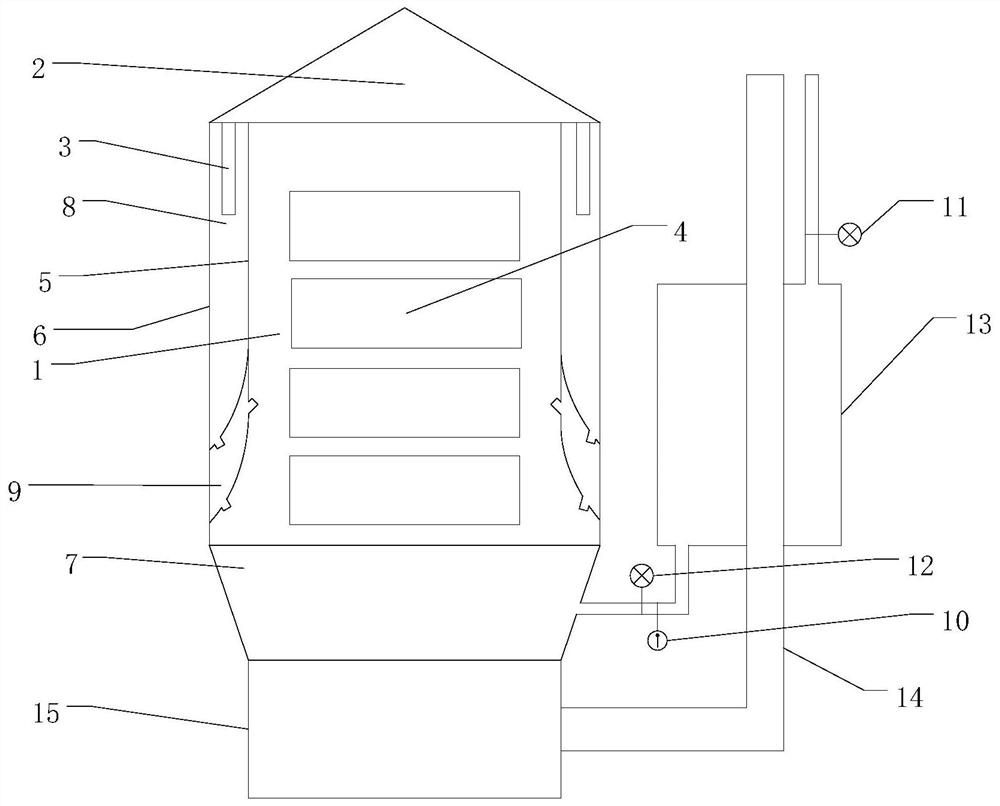

[0019] Such as figure 2 As shown, the gas steamer of the present invention includes a steamer main body 1 and a plurality of steaming drawers 4 located inside the steamer main body 1, a heating water tank 7 is provided under the steamer main body 1, and a gas heating furnace 15 is arranged below the heating water tank 7, The gas heating furnace 15 heats the heating water tank 7, and the steam generated in the heating water tank 7 enters the inside of the main body of the steamer to realize heating and cooking of the staple food in the steamer 4.

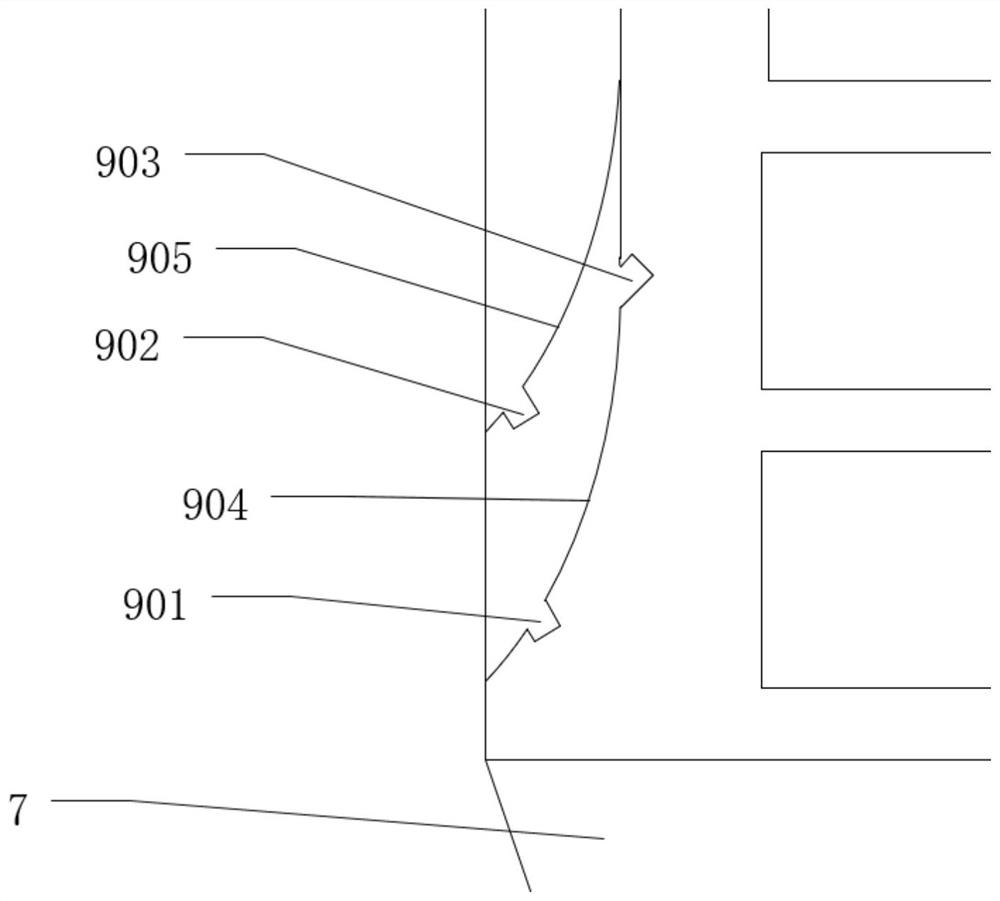

[0020] Such as figure 2 As shown, in one embodiment, the steam box main body 1 is cylindrical, the steam box main body 1 has an outer layer 6, and the inside of the steam box main body also has an annular inner layer 5, and the inner layer There is a backflow room 8 between the outer wall of 5 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com