Three-connecting-rod turnover mechanism

A flip mechanism and three-link technology, applied in the field of sheet metal welding, can solve the problems of difficult balance, large cylinder loss, complicated design, etc., and achieve the effect of smooth opening and locking, reducing buffer amount, and easy installation and fixation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

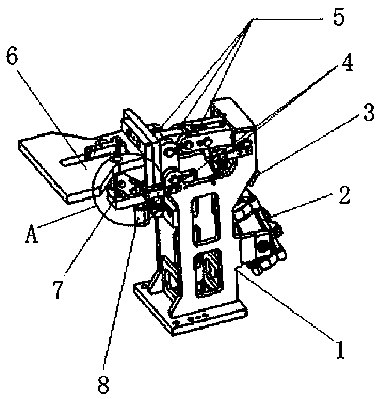

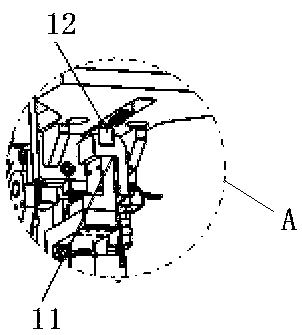

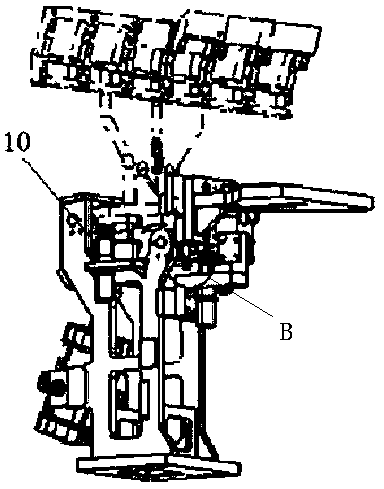

[0025] refer to Figure 1-6 In this embodiment, a three-link turning mechanism is proposed, including a base 1, and a cylinder and its component 2 are installed on one side of the base 1, and the cylinder and its component 2 include the cylinder and the cylinder component. Position device 3 and two sensing devices 4, the two sensing devices 4 are respectively sensing device A and sensing device B, the two sensing devices 4 are located on one side of the retracting limit device 3, and the top of the base 1 is provided with three connecting rods Mechanism 5, one side of the three-link mechanism 5 is provided with an overturning assembly 6, the bottom of the overturning assembly 6 is provided with a clamping and limiting device 7, and the clamping and limiting device 7 includes a limiting pressure block 12 and a limiting bracket 11, One side of the base 1 is provided with a cylinder retraction limit device 9 and a cylinder retraction buffer device 10, a limit bolt 13 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com