Device for automatically sleeving pipe fitting plug with sealing ring

A sealing ring and plug technology, which is applied in the field of non-standard production mode of automatic sleeve sealing ring for pipe fittings, can solve the problems of unfavorable sealing ring product debugging flexibility, high process loss cost, unfavorable long-term stability of equipment, etc., and achieves environmental dependence. Minimal sex, easy installation and operation, novel design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

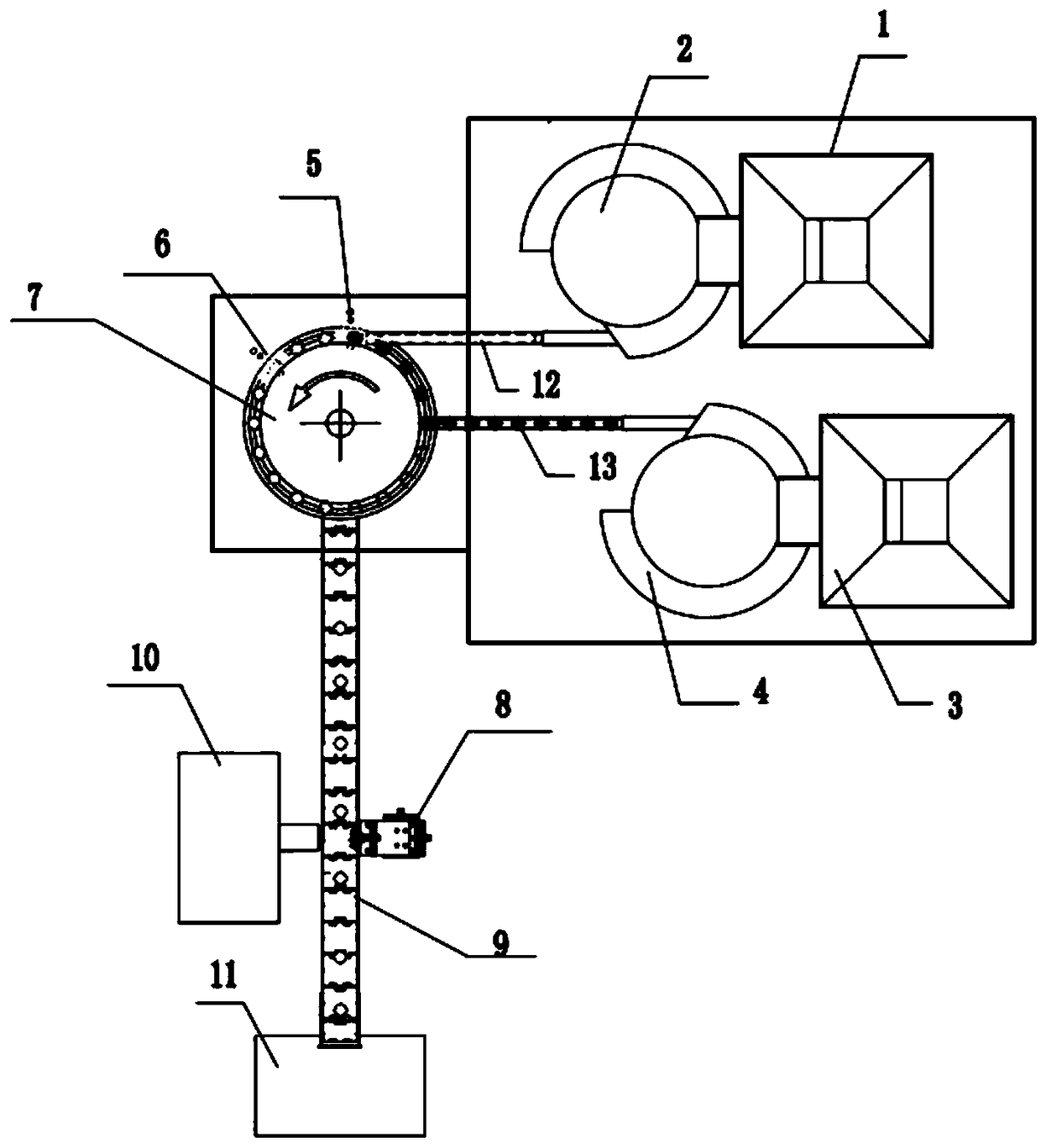

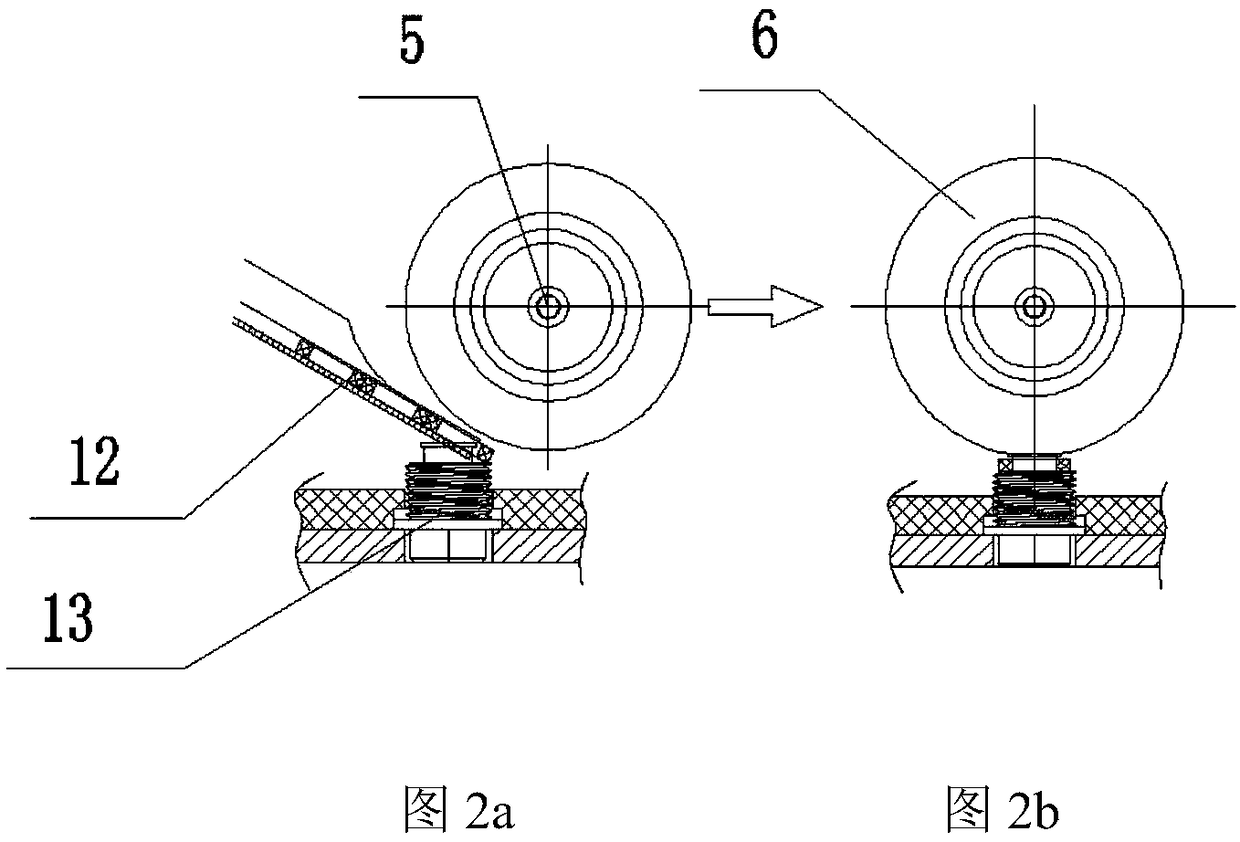

[0029] A sealing ring device for automatic plugging of pipe fittings, which includes a sealing ring vibrating bin, a sealing ring vibrating plate, a plug vibrating bin, a plug vibrating plate, an assembly wheel assembly, a leveling wheel assembly, a material receiving turntable, and a camera detection device , product conveyor belt, unqualified product material box, qualified product material box, sealing ring and plug;

[0030] Among them, the sealing ring vibrating hopper is connected with the sealing ring vibrating plate through the lifting belt, so that the sealing ring is lifted into the sealing ring vibrating plate, and the sealing ring vibrating plate is connected with the sealing ring trough behind the sealing ring vibrating plate, so that the sealing ring slides to the bottom of the assembly wheel; The vibrating silo is connected to the plug vibrating plate through the lifting belt, so that the plug is lifted into the plug vibrating plate, and the plug vibrating plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com