A three-station polishing machine for mechanical parts

A mechanical accessories, three-station technology, used in grinding/polishing equipment, grinding/polishing safety devices, manufacturing tools, etc., can solve problems such as unrealizable, affecting the processing quality of mechanical accessories, and achieve reasonable structural design and protection. Good effect and easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

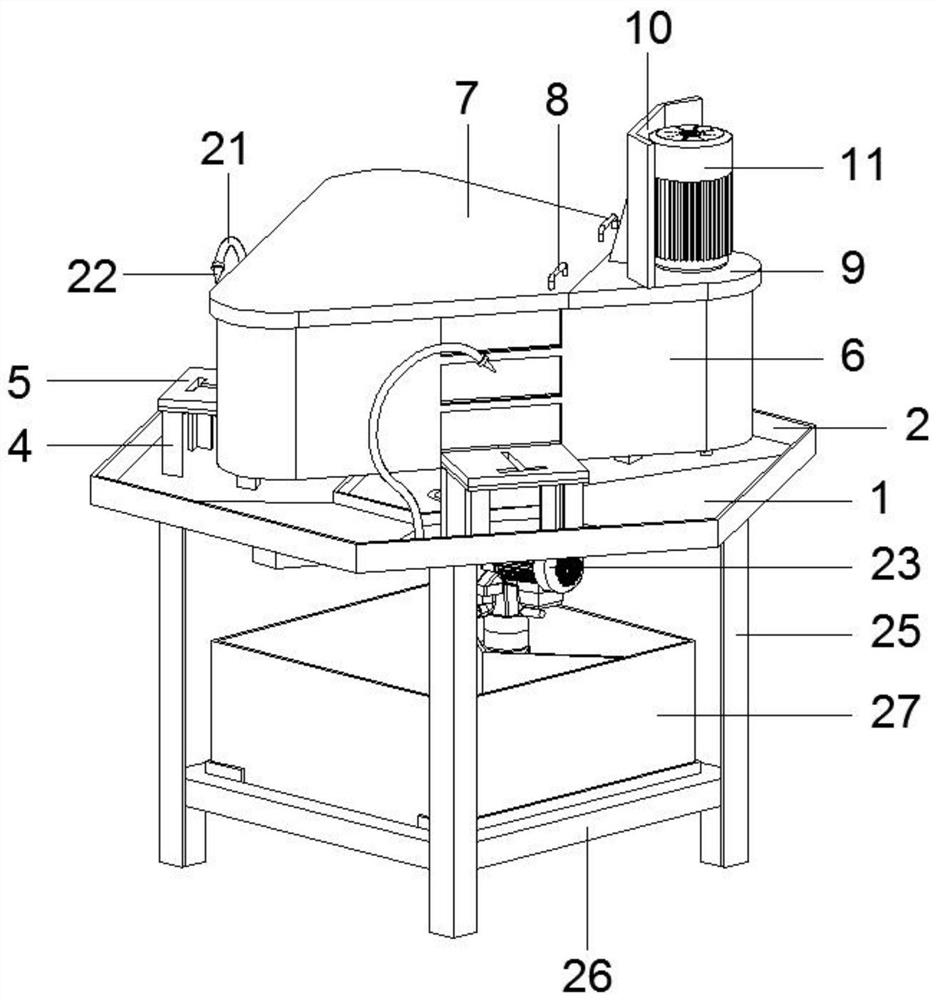

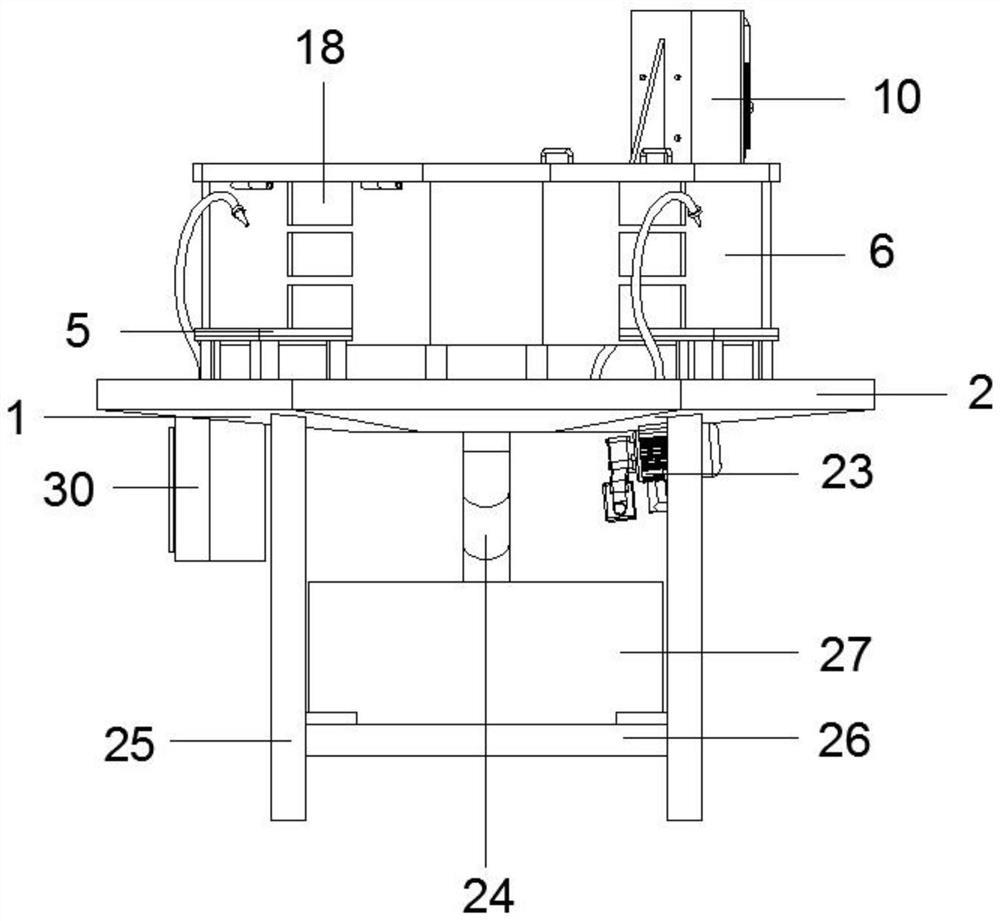

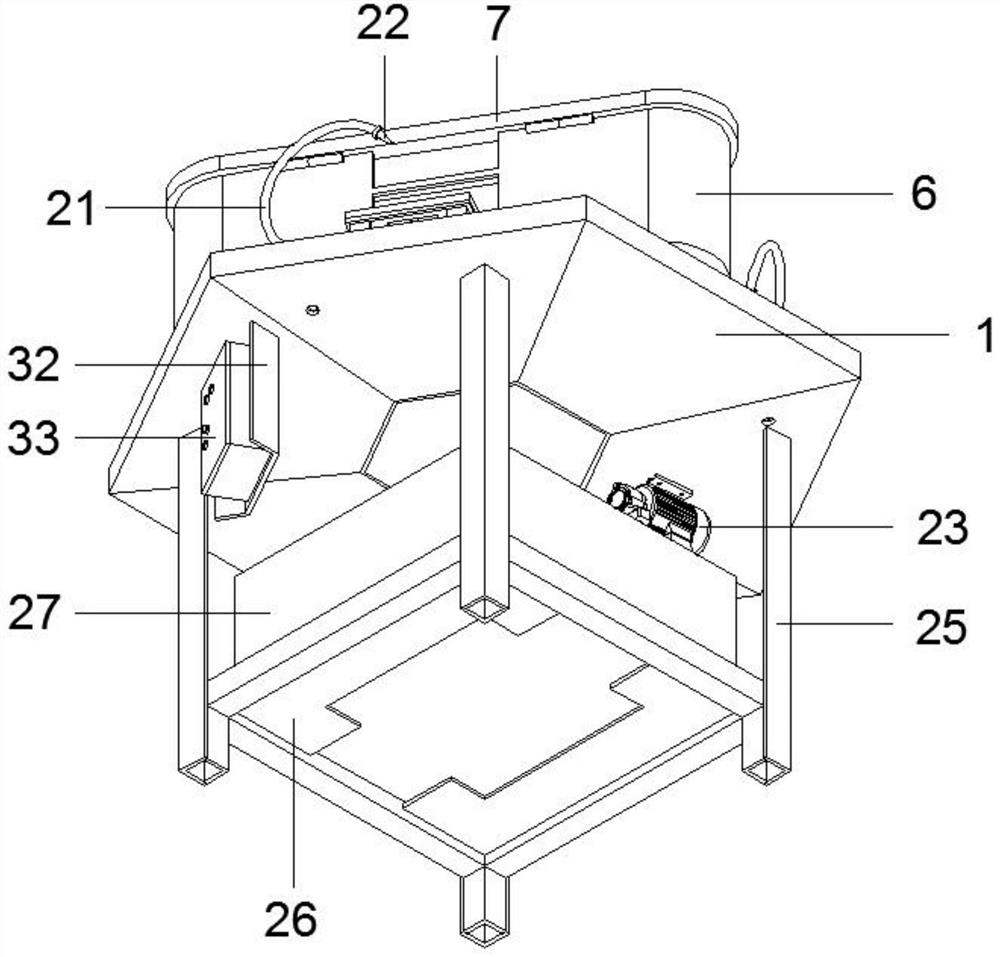

[0036] A three-station polishing machine for mechanical accessories, including: base plate 1, outer baffle plate 2, inner baffle plate 3, support column 4, workbench 5, base 6, cover plate 7, handle 8, end cover 9, motor seat 10 , driving motor 11, transmission shaft 12, driving wheel 13, driven wheel 14, tensioning wheel mount 15, tensioning wheel mounting bracket 16, tensioning wheel 17, abrasive belt 18, base 19, jacking bolt 20, water supply Pipe 21, nozzle 22, water pump 23, drain pipe 24, support leg 25, water tank mount 26, water collection tank 27, partition 28, filter screen mount 29, sedimentation tank 30, clear water tank 31, main control box mount 32 , the main control box 33; the outer baffle 2 is arranged on the edge of the outer side of the bottom plate 1 by welding, and the inner baffle 3 is arranged on the middle position of the bottom plate 1 by welding; the support column 4 is arranged on the top of the bottom plate 1 by welding , and the workbench 5 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com