Efficient steering method for ship

It is a high-efficiency technology for ships, which can solve the problems of low rudder turning efficiency and achieve high rudder turning efficiency, improve efficiency, and increase output torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

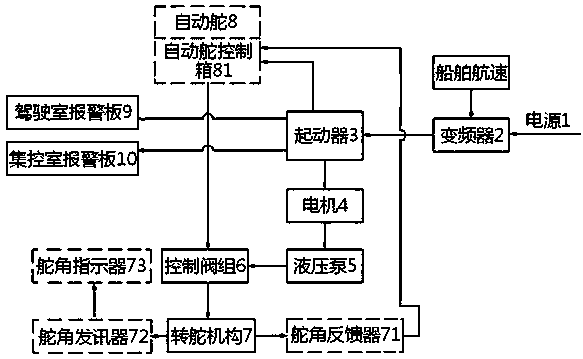

[0041] see figure 1 , a high-efficiency ship steering method, the ship steering method includes the following steps: first set a frequency converter 2 between the starter 3 and a power supply 1, and then according to the predetermined steering speed requirements of the steering mechanism 7, through the frequency converter 2 Adjust the output frequency of the power source 1 flowing to the starter 3 to adjust the rotation speed of the motor 4, then adjust the rotation speed of the hydraulic pump 5 by the motor 4, and then adjust the steering speed of the steering mechanism 7 by the hydraulic pump 5 to achieve the predetermined rotation speed The steering speed of the rudder mechanism 7, and then the direction of the rudder blades is adjusted by the steering mechanism 7 to adjust the navigation direction of the ship; the output frequency adjusted by the frequency converter 2 and the steering speed of the steering mechanism 7 are one by one Correspondingly, the rudder turning spee...

Embodiment 2

[0043] Basic content is the same as embodiment 1, the difference is:

[0044] The steering speeds corresponding to the high, middle and low gears are 65° / 28s, 65° / 20s, and 65° / 14s respectively. Said high, middle and low speeds correspond to the following: above 11 knots is the high speed, between 11-7 knots is the middle speed, and below 7 knots is the low speed.

Embodiment 3

[0046] Basic content is the same as embodiment 1, the difference is:

[0047] The starter 3 is provided with a PLC, the input end of the PLC is connected to the speed signal, and the input end of the PLC is connected to the frequency converter 2 to control the frequency converter 2 according to the speed signal received by the PLC. , so as to adjust the output frequency of the power supply 1 flowing to the starter 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com