Clothes treatment equipment

A clothing treatment equipment and technology for clothing treatment, applied in other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of inconvenient user operation, high control panel, inconvenient washing tub control, etc., and achieve convenient washing additives, enhanced The effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

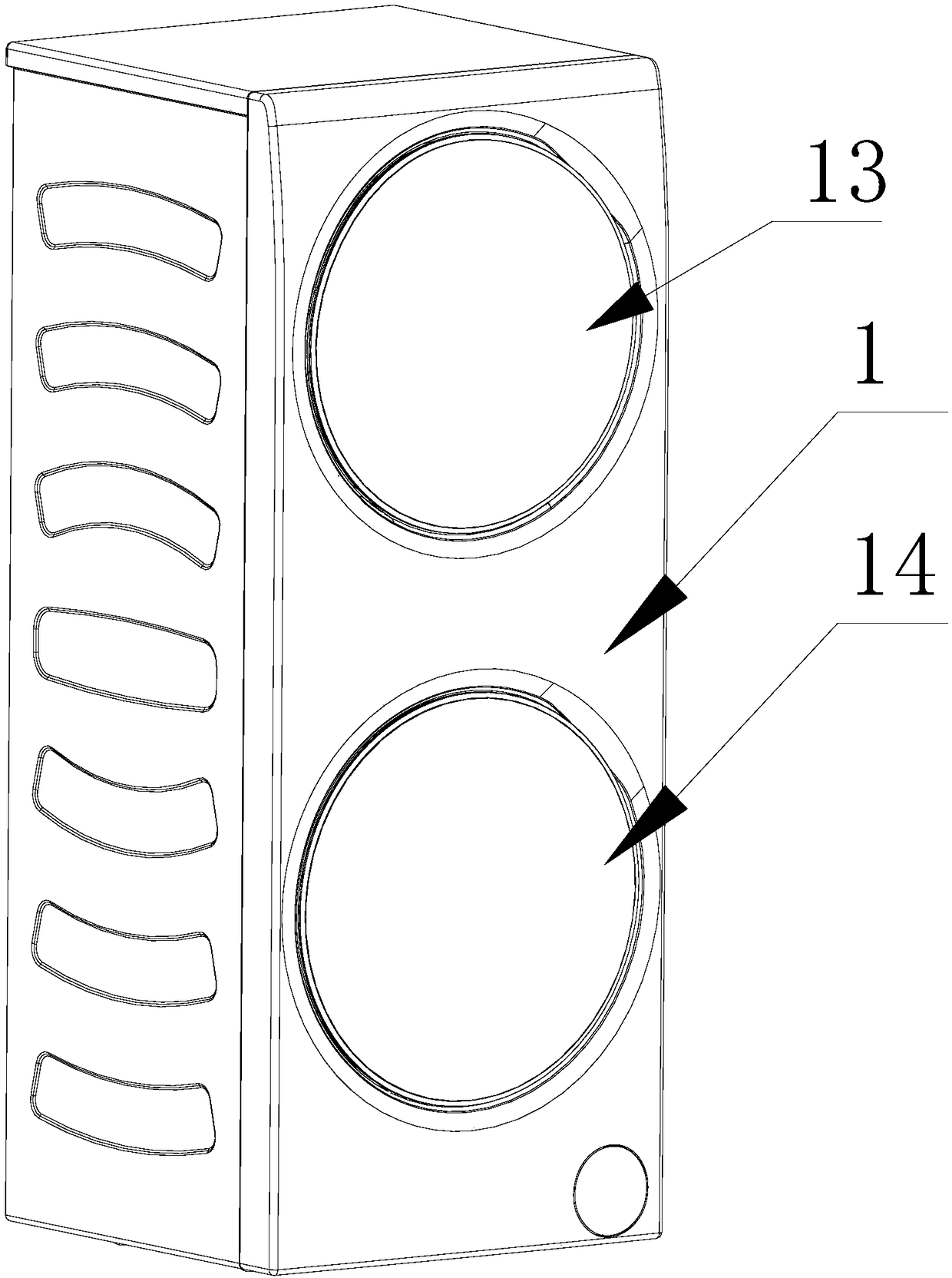

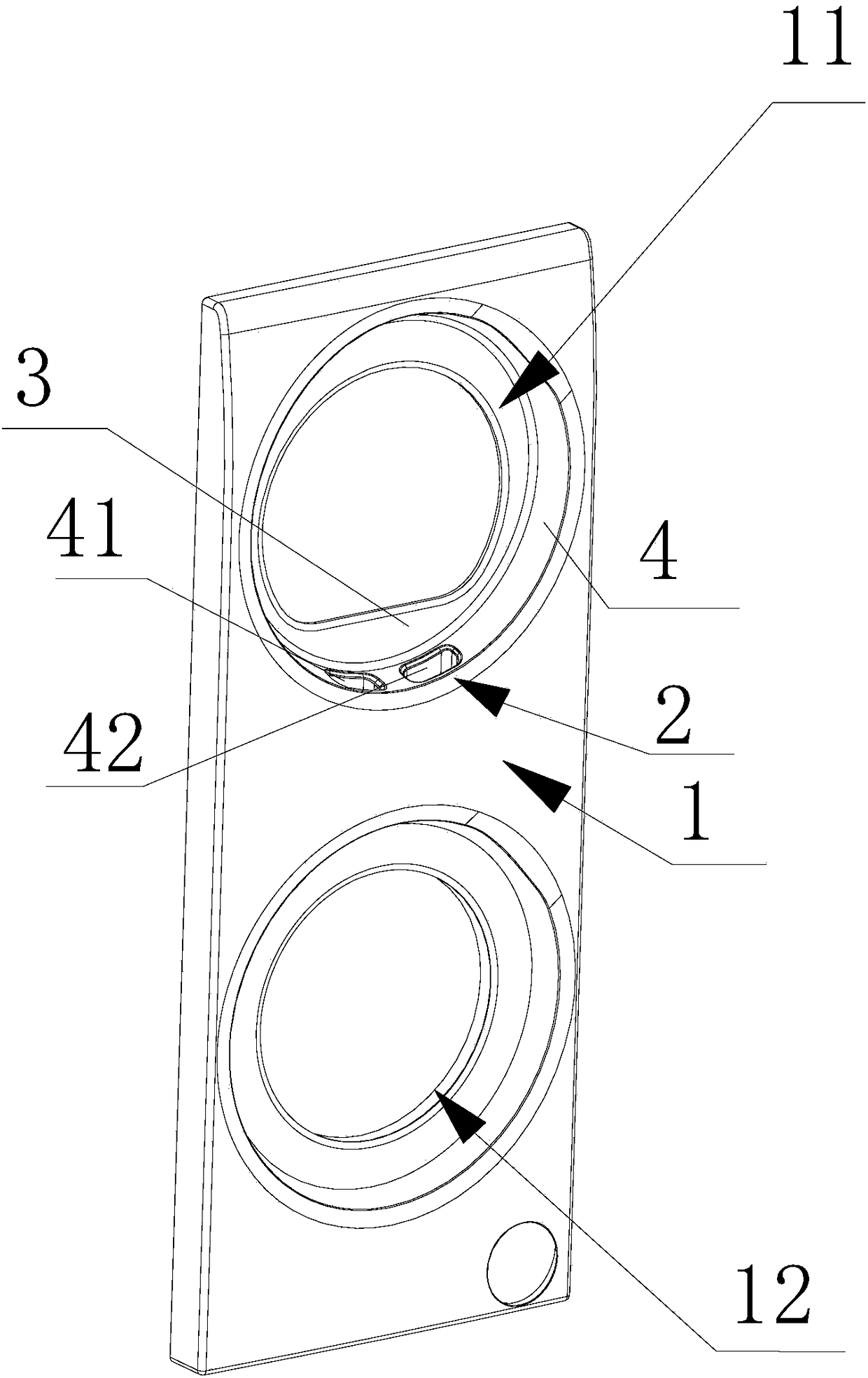

[0050] see Figure 1-Figure 3 As shown, this embodiment provides a clothes processing device, including a clothes processing cylinder and a front panel 1 located at the front of the clothes treatment cylinder. The front panel 1 is provided with a clothes insertion port, and the front panel 1 is located The outer peripheral surface is recessed to form an installation space, and the door of the laundry treatment equipment is installed in the installation space, and a washing additive injection port 22 is also arranged in the installation space.

[0051] In the above scheme, by setting the detergent additive inlet 2 at the clothes inlet, the detergent additive inlet 2 can be opened / closed through the door of the clothes processing device, which facilitates the user to inject detergent, and simultaneously The additive injection port 2 is arranged in the installation space, and the integrated structure of the front panel 1 of the whole machine is retained, so that the front panel 1...

Embodiment 2

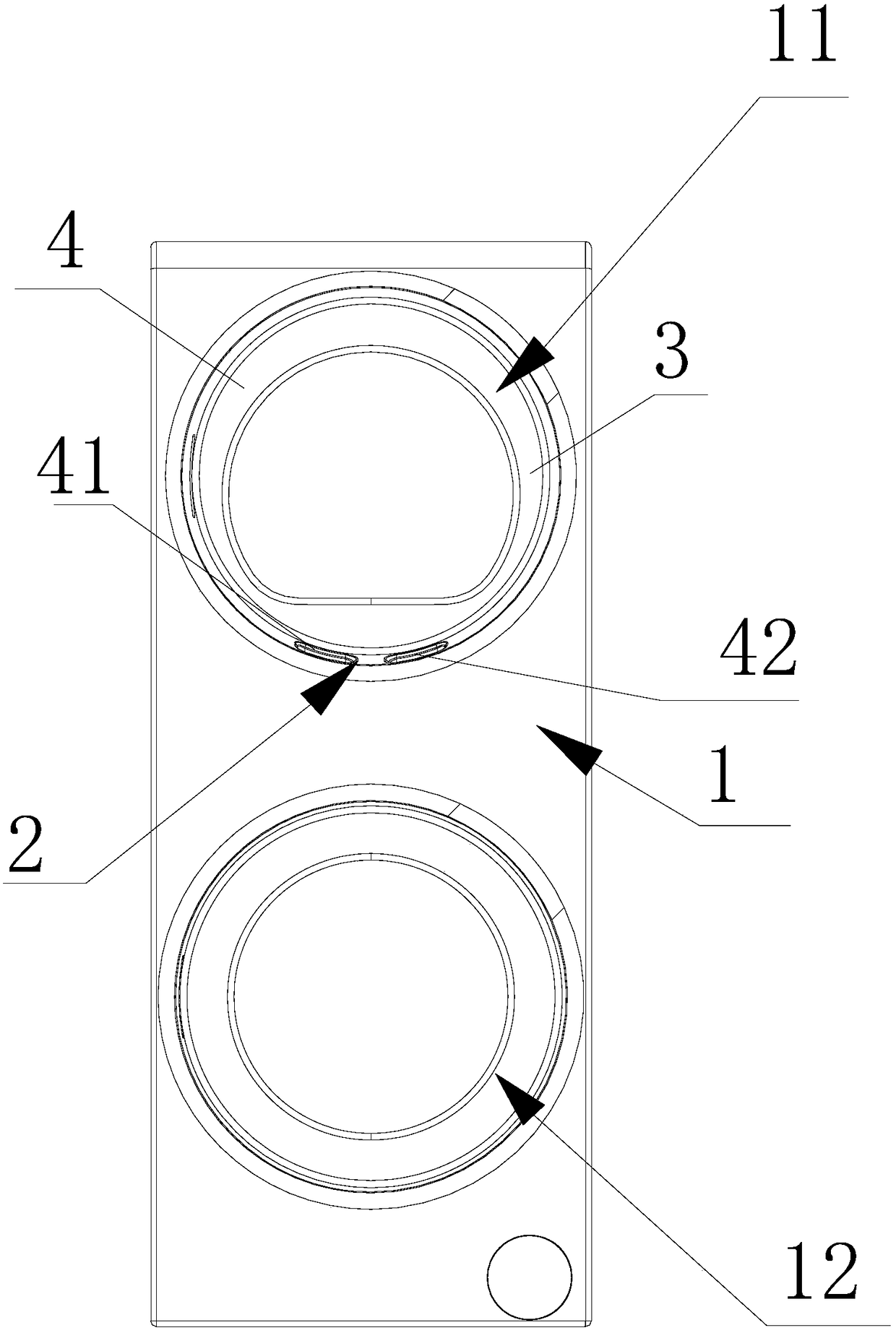

[0075] Embodiment 2 On the basis of Embodiment 1, the laundry processing device is further disclosed. The laundry processing device includes a first laundry processing cylinder and a second laundry processing cylinder arranged up and down. The front panel, the front panel is provided with a first machine door and a second machine door up and down, at least one of the doors is provided with a control panel assembly.

[0076] In the above scheme, according to the characteristics of the Gemini clothing processing equipment, the control panel assembly is set on the higher door, which is convenient for the user to view the screen of the control panel assembly from the perspective of the user, and also facilitates the user to input control commands from the control panel , the structural design is more suitable for twin clothes processing equipment, and the user experience is better.

[0077] Preferably, the first machine door or the second machine door includes a door body and an o...

Embodiment 3

[0094] Embodiment 3 On the basis of the above embodiments, other structures of the clothes processing equipment are further designed to achieve the technical effect of integrating the front panel, specifically:

[0095] In the third embodiment, the laundry processing equipment includes a first laundry processing cylinder and a second laundry processing cylinder arranged up and down, and a drying module is also arranged in the laundry processing equipment, which is used to provide drying air to the laundry processing device to dry dry laundry.

[0096] Further, the drying module is a condenser drying module including a base, a condenser arranged on the base, and a cooling air duct arranged on the base for cooling the condenser, and the condenser is connected with the clothes processing equipment for drying. The air duct is connected, and the side panel or the rear cover of the casing of the clothes processing device is provided with an air inlet for feeding into the cooling air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com