Hydrofractured water production shale gas well shale gas yield predicting method

A technology for shale gas well and production prediction, which is applied in the directions of measurement, earthwork drilling and production, wellbore/well components, etc., and can solve the problems of large shale gas production prediction error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

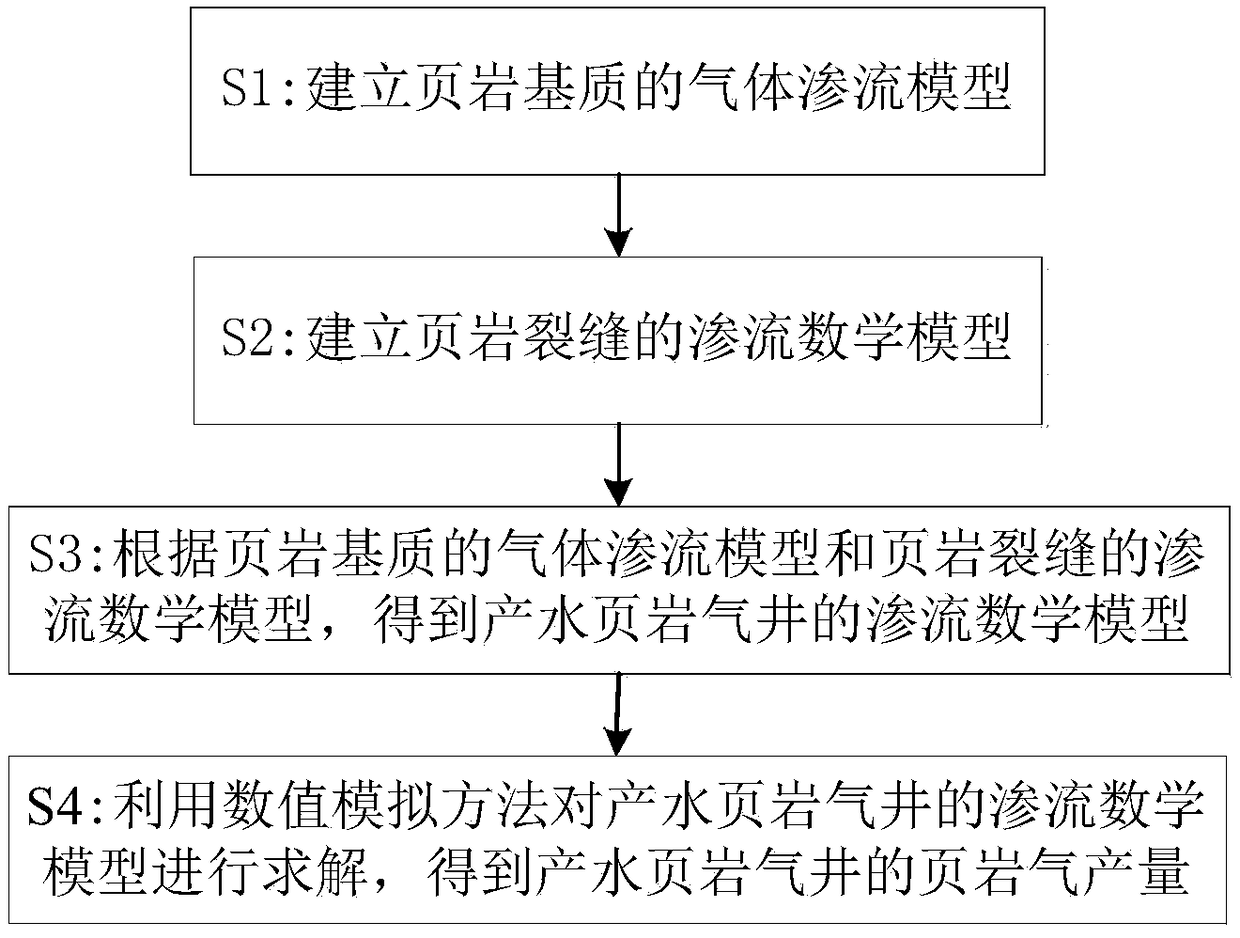

[0070] A shale gas production prediction method for water-producing shale gas wells through hydraulic fracturing. The assumptions include: 1. The shale reservoir is composed of well-developed and interconnected natural fractures and matrix; 2. The artificial fractures are double-winged. Symmetrical vertical fractures, the fracture height is equal to the thickness of the gas reservoir; 3. The temperature remains constant during the production process of the gas reservoir, and the influence of gravity is ignored.

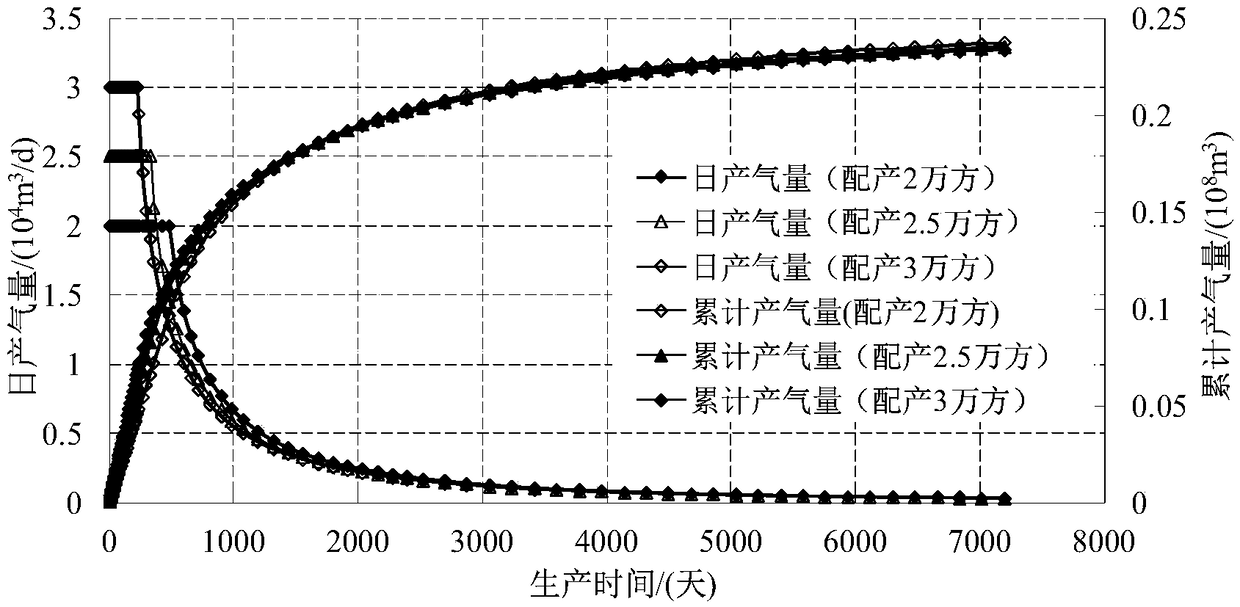

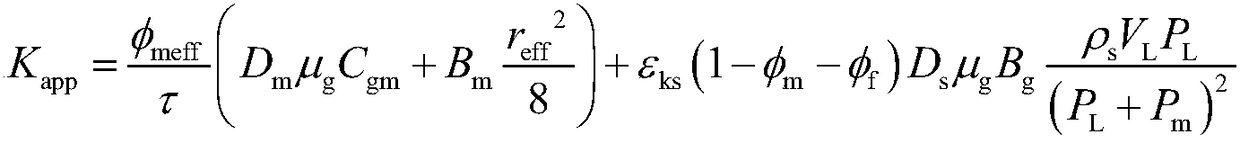

[0071] Due to the coexistence of adsorbed gas and free gas in shale, it is different from conventional gas reservoirs where most of the free gas is present, and also different from coalbed methane that mainly exists in coal matrix pores in an adsorbed state, that is, it is necessary to consider both the elastic release of free gas and the adsorption o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com