Void-preventing visual pouring method for second-lining concrete of tunnel

A tunnel and anti-shedding technology, applied in the direction of tunnel lining, tunnel, wellbore lining, etc., can solve the problem of lack of economical reliability in the prevention and control of the secondary lining of the tunnel, so as to reduce project quality risks, improve construction quality and efficiency, and achieve high application and reliability. The effect of promoting value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

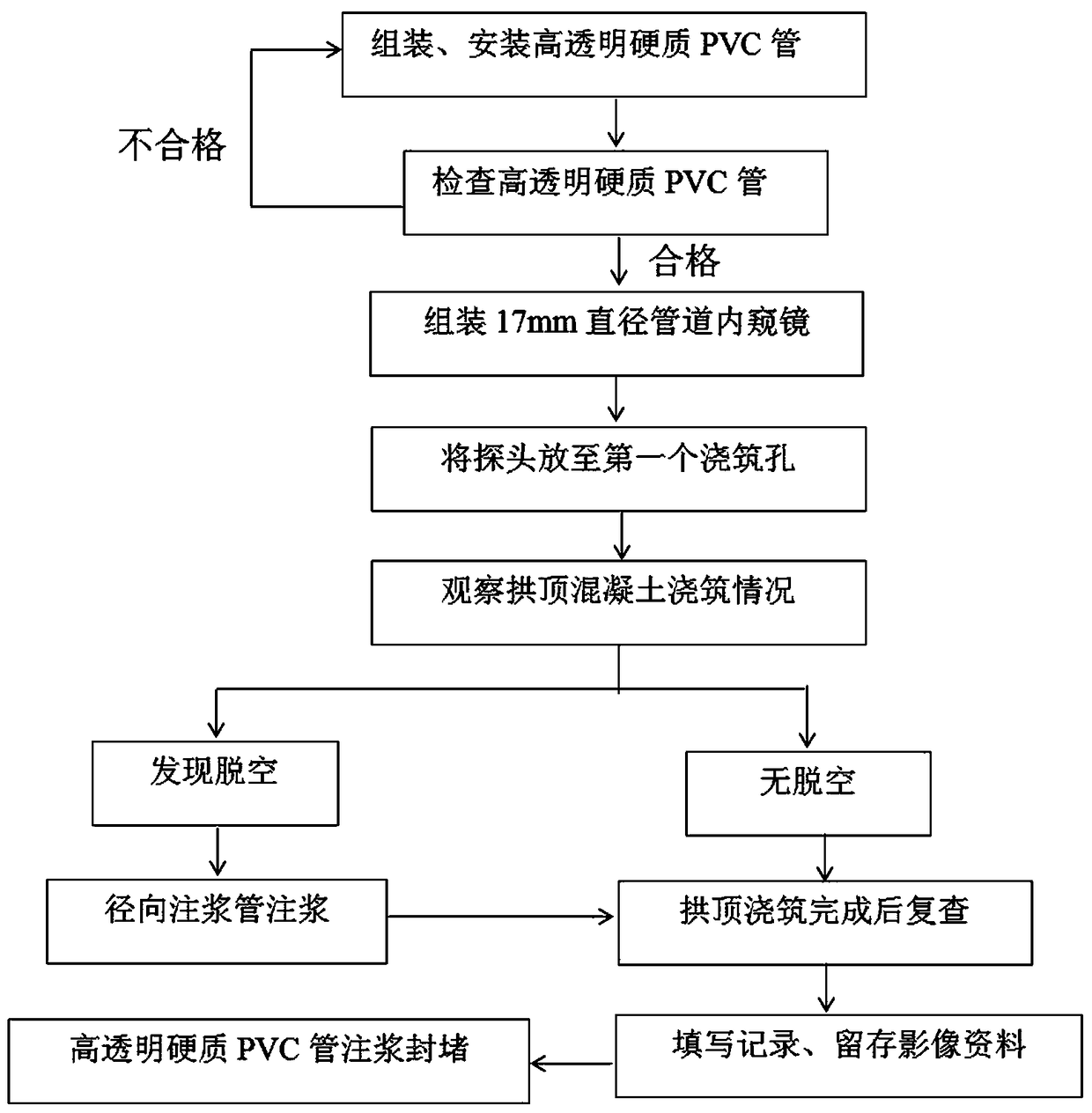

[0017] A method for visual pouring of tunnel second-lined concrete for void prevention, comprising the following steps:

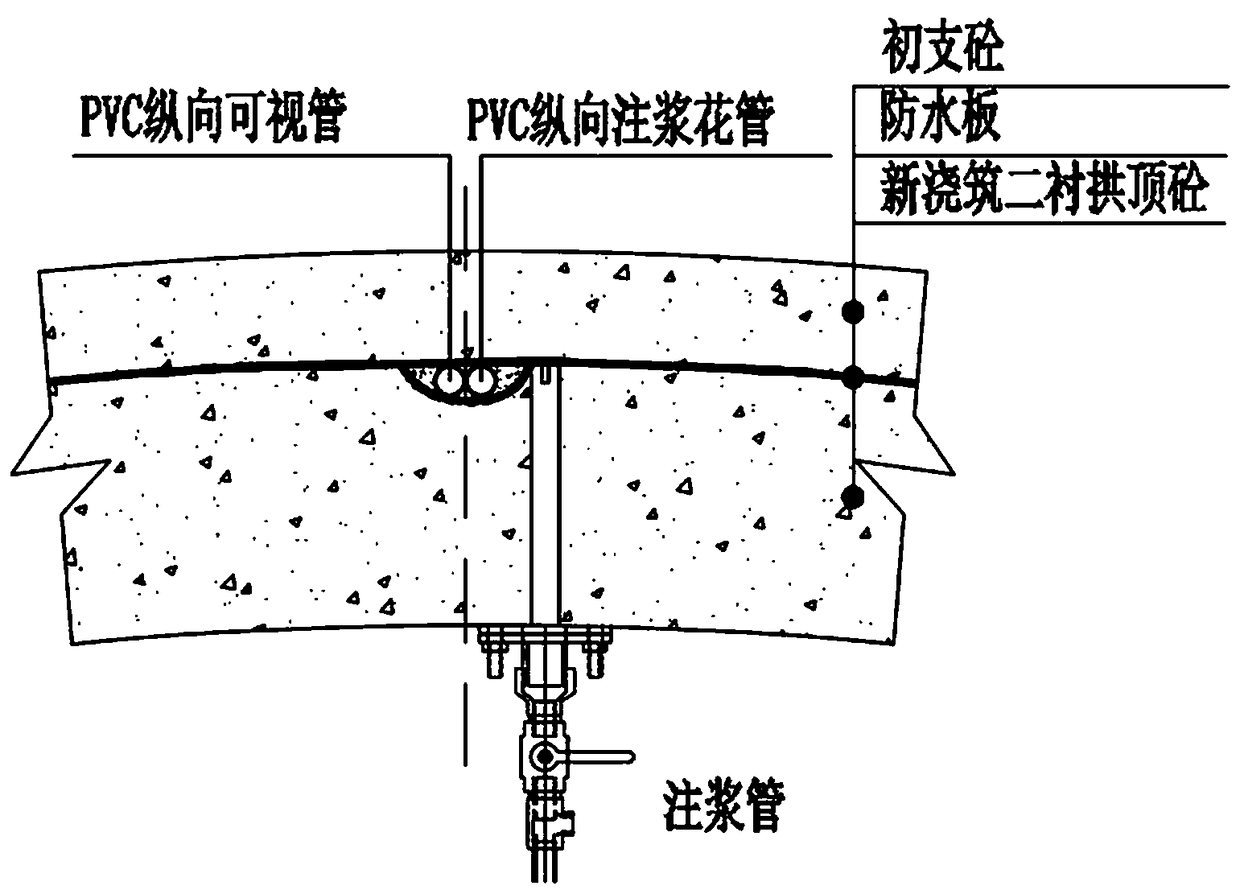

[0018] Step (1): During the pouring process of the second lining of the tunnel, a transparent rigid PVC pipe is arranged longitudinally, and the transparent rigid PVC pipe is arranged side by side with the longitudinal grouting pipe and the exhaust pipe of the vault;

[0019] Step (2): Place a visible probe in the transparent rigid PVC pipe during the pouring process;

[0020] Step (3): Put the visual probe into the first pouring hole to observe the pouring of the vault concrete. If void is found, enter step (3.1); if void is found, proceed to step (3.2);

[0021] Step (3.1): After the void is found, inject grout into the radial grouting pipe and pour again. After the pouring is completed, enter step (3.2);

[0022] Step (3.2): After the vault pouring is completed, review, fill in the records, save the image data, take out the visible probe, and grout the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com