Construction method for rock-entering cast-in-situ bored piles with diameter of less than 1.5m

A technology of bored piles and construction methods, which is applied in the direction of sheet pile walls, foundation structure engineering, foundation structure tests, etc. It can solve problems such as inability to salvage quality and equipment, drill bits are easy to get stuck in rock formations, and drilling efficiency is reduced. Achieve the effect of reducing project quality risk, shortening construction period, and fast hole forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

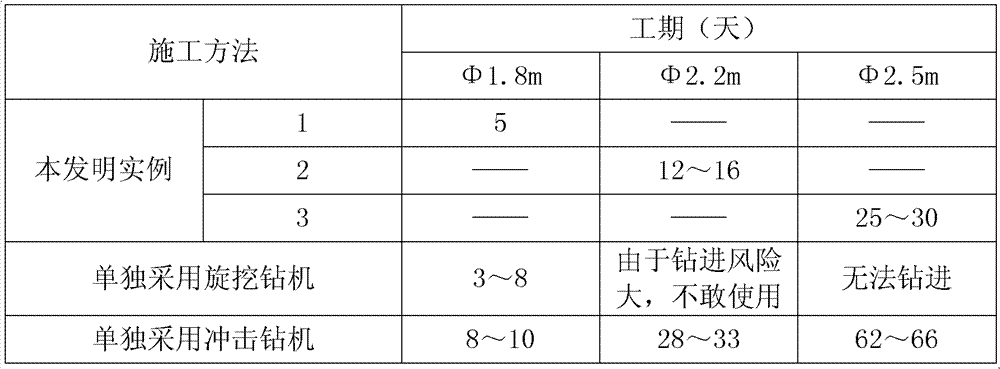

[0025] Embodiment 1: The design value of the borehole diameter is 1.8 meters.

[0026] A construction method for rock-in-place bored piles with a diameter > 1.5 meters, the steps of which are as follows:

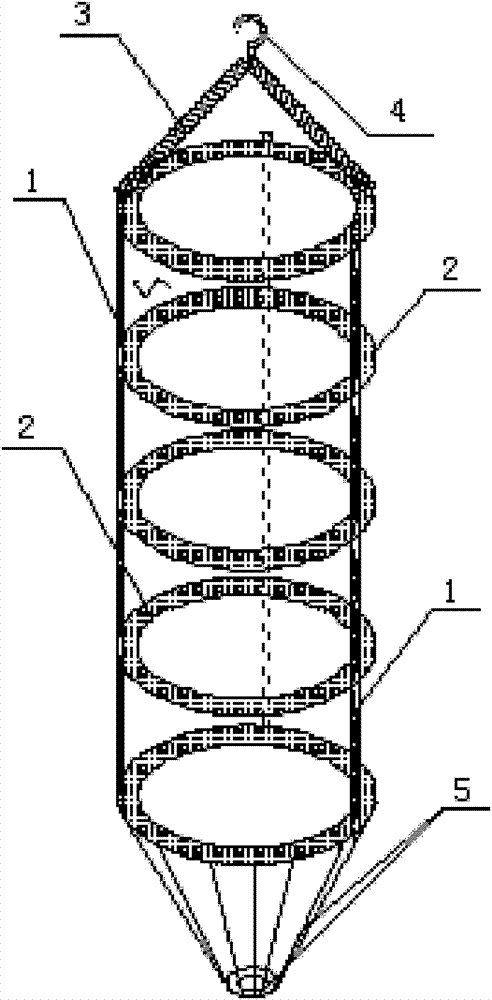

[0027] 1) Do a good job of preparation before construction, and carry out measurement and setting-out and lower casing 1, the diameter of casing 1 is 200 mm larger than the set drilling diameter;

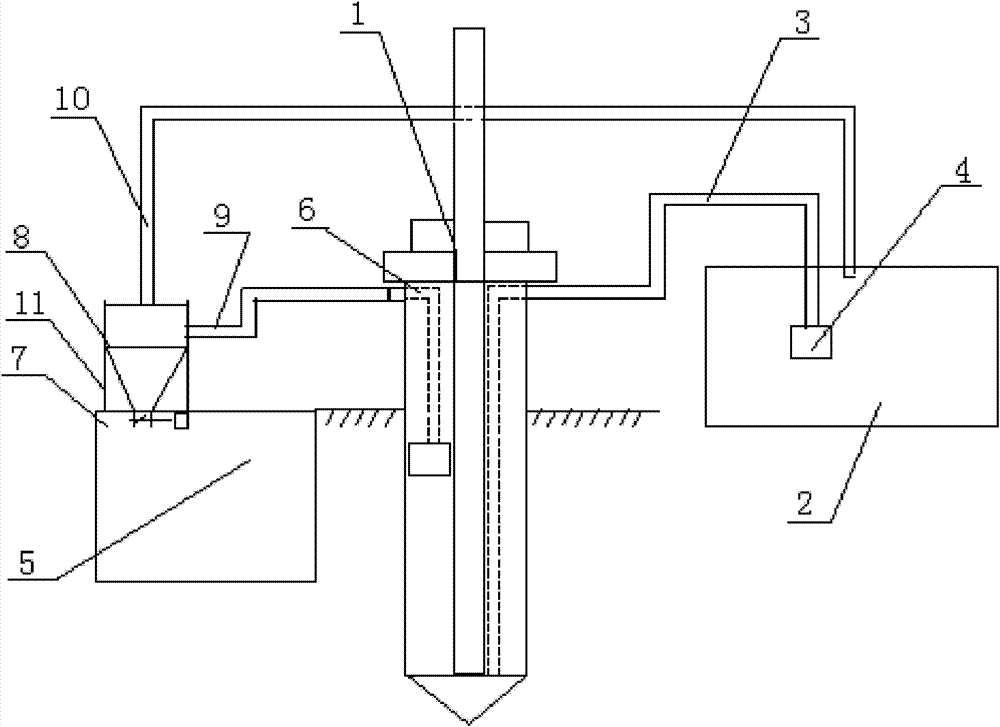

[0028] 2) Once the casing is in place, use a rotary excavator with a drill bit diameter 18-20 mm smaller than the set hole diameter to drill to the hole bottom elevation. For replacement, the device for separating mud by piling is mainly composed of pile driver 1, mud pool 2, mud delivery pipe 3, mud pump one 4, mud pump two 5, mud discharge pipe 6, mud sedimentation tank 7, in mud The upper end of the sedimentation tank 7 is installed with a conical sand-stone separator 8 through a bracket 11, and the mud inlet pipe 9 connected and connected between the conical sand-stone separa...

Embodiment 2

[0039] Embodiment two: the borehole diameter design value is 2.2 meters:

[0040] A construction method for rock-in-place bored piles with a diameter > 1.5 meters, the steps of which are as follows:

[0041] 1) Do a good job of preparation before construction, and carry out measurement and setting-out and lower casing 1, the diameter of casing 1 is 250 mm larger than the set drilling diameter;

[0042] 2) Once the casing is in place, use a rotary excavator with a drill bit diameter smaller than the set drilling diameter of 22mm to drill the hole to the bottom elevation. Carry out replacement and control the mud index in the borehole as follows: general strata: relative density is 1.12-1.15, viscosity is 18-20); easily collapsed stratum: relative density is 1.28-1.40, viscosity is 21-27s; rock formation: relatively The density is 1.12-1.14, the viscosity is 25-30s; the sand content rate is 3.0%, and the colloidal rate is 96.5%;

[0043] 3) Use the aforementioned pile hole hol...

Embodiment 3

[0053] Embodiment three: the set value of the borehole diameter is 2.5 meters:

[0054] A construction method for rock-in-place bored piles with a diameter > 1.5 meters, the steps of which are as follows:

[0055] 1) Do a good job of preparation before construction, and carry out measurement and setting-out and lower casing 1, the diameter of casing 1 is 300 mm larger than the set drilling diameter;

[0056] 2) Once the casing is in place, use a rotary excavator with a drill bit diameter smaller than the set drilling diameter of 30mm to drill the hole to the bottom elevation. Replacement; general strata: relative density is 1.15-1.20, viscosity is 20-22s; easily collapsed stratum: relative density is 1.30-1.45, viscosity is 22-28s; rock formation: relative density is 1.12-1.15, viscosity is 28-35s ;Sand content rate is 6%, colloid rate is 97.5%;

[0057] 3) Use the aforementioned pile hole hole type detection device to detect the verticality and aperture of the borehole. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com