Double-station control module for E-AMT clutch

A control module and double-station technology, applied to clutches, fluid-driven clutches, non-mechanical drive clutches, etc., to achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

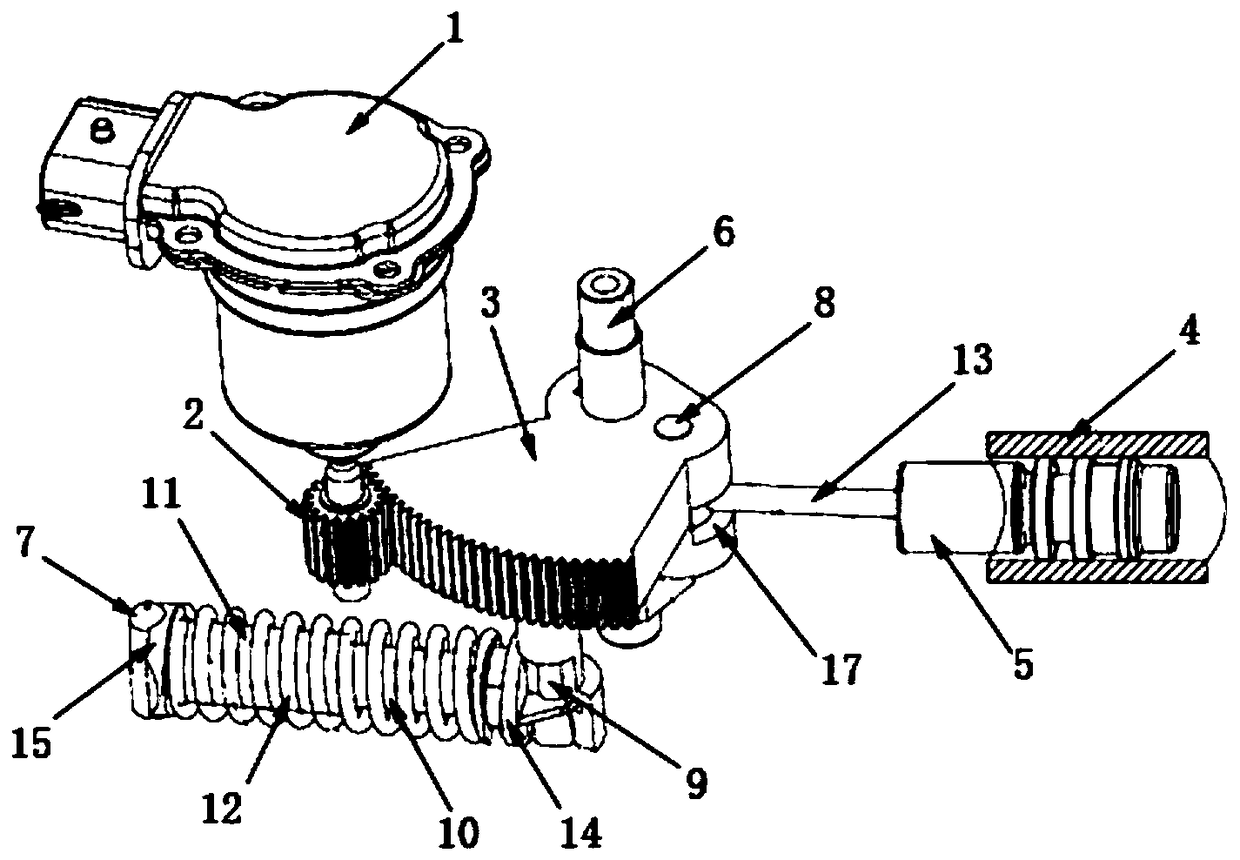

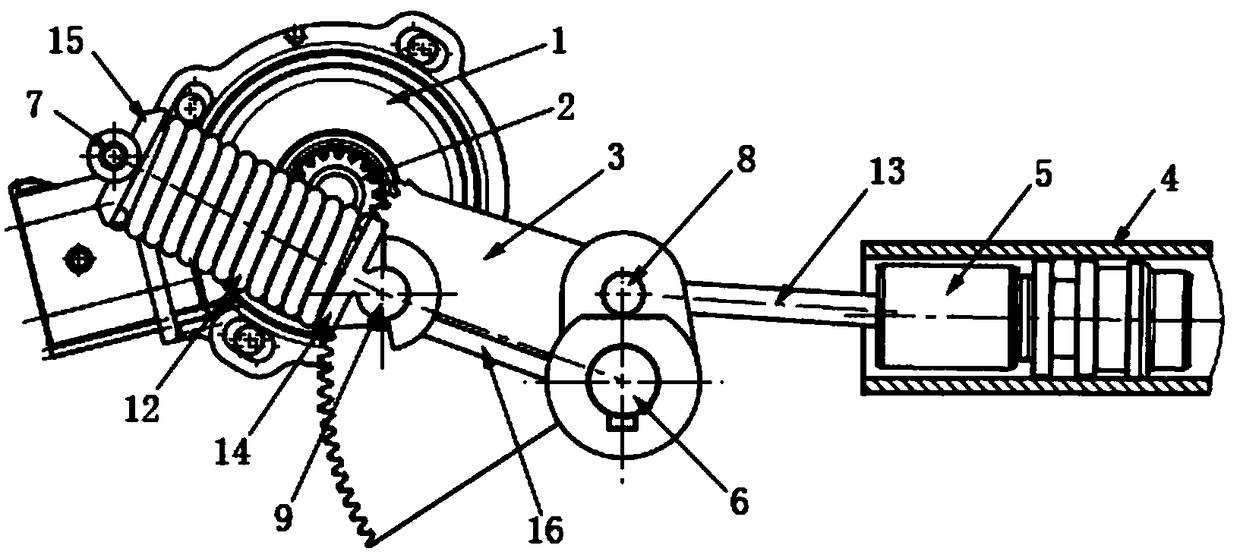

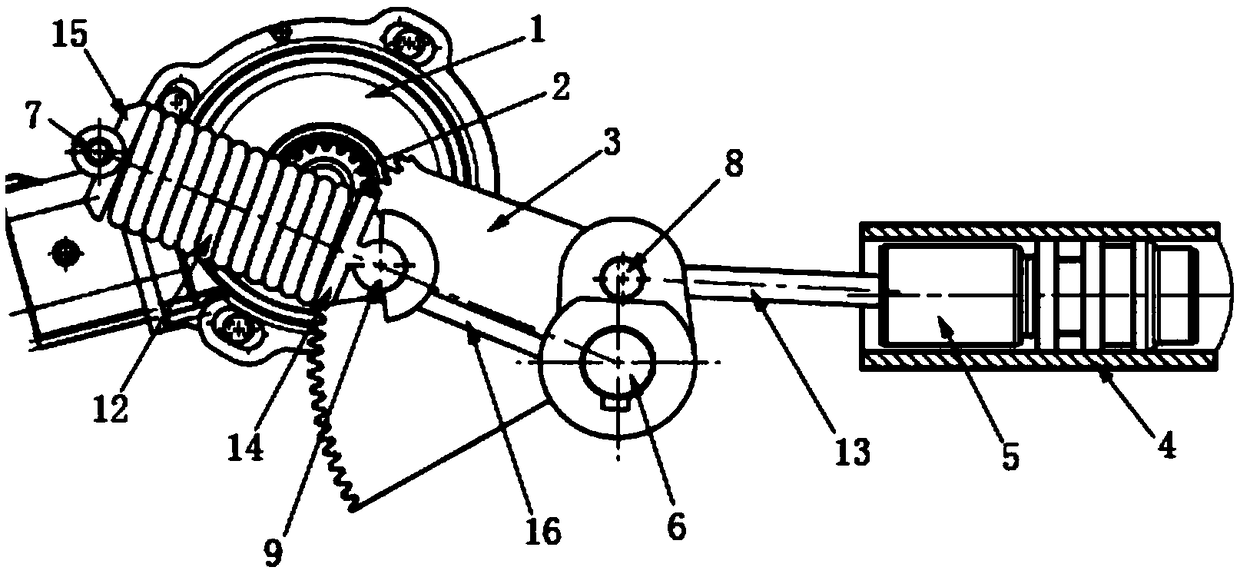

[0032] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 4 As shown, one end of the ejector rod 10 is provided with a first stopper 14, which is rotatably connected with the fourth central shaft 9, and the other end of the sleeve 11 is provided with a second stopper 15, which is connected to the second stopper 15. The second central shaft 7 is rotatably connected, and the spring 12 abuts between the first block 14 and the second block 15 . Preferably, the first block 14 is integrally formed with the ejector rod 10 , and the second block 15 is integrally formed with the sleeve 11 .

[0033] In a further embodiment of the present invention, the first block 14 is fixedly connected to the first central shaft 6 through a connecting rod 16 .

[0034] In a further embodiment of the present invention, one end of the connecting rod 16 is fixedly connected to the first stopper 14 , the other end of the connecting rod 16 is sleeved on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com