Power planning method based on operating power consumption of robot, robot and chip

A robot and power consumption technology, applied in battery circuit devices, battery over-discharge protection, collectors, etc., can solve problems such as reducing product life and battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions in the embodiments of the present invention will be described in detail below with reference to the drawings in the embodiments of the present invention.

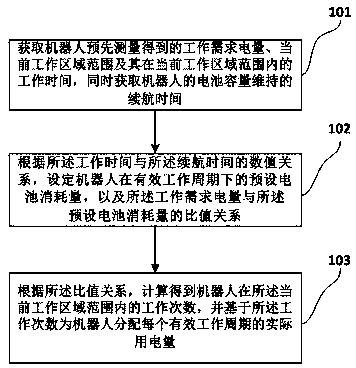

[0016] figure 1 It is a flow chart of a power planning method based on the working power consumption of the robot provided by the embodiment of the present invention. The robot is a cleaning robot in the embodiment of the present invention, which carries a rechargeable lithium battery inside and has the function of automatically returning to the seat for charging.

[0017] like figure 1 As shown, in step 101, the work demand power measured in advance by the robot, the current work area and its working time in the current work area are obtained, and the battery life of the robot is obtained at the same time; wherein, the current work area is The cleaning area pre-marked by the robot on the grid map, the power demand for work is based on the battery power consumed by the robot to completely cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com