An environmentally friendly polymer composite self-repairing waterproof material and its preparation method

An environmentally friendly, waterproof material technology, applied in epoxy resin coatings, chemical instruments and methods, layered products, etc., can solve problems such as environmental pollution, adverse effects of building fire protection, and reduced protective performance of roofing materials, and achieve short repair time. , good self-healing performance, good anti-leakage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

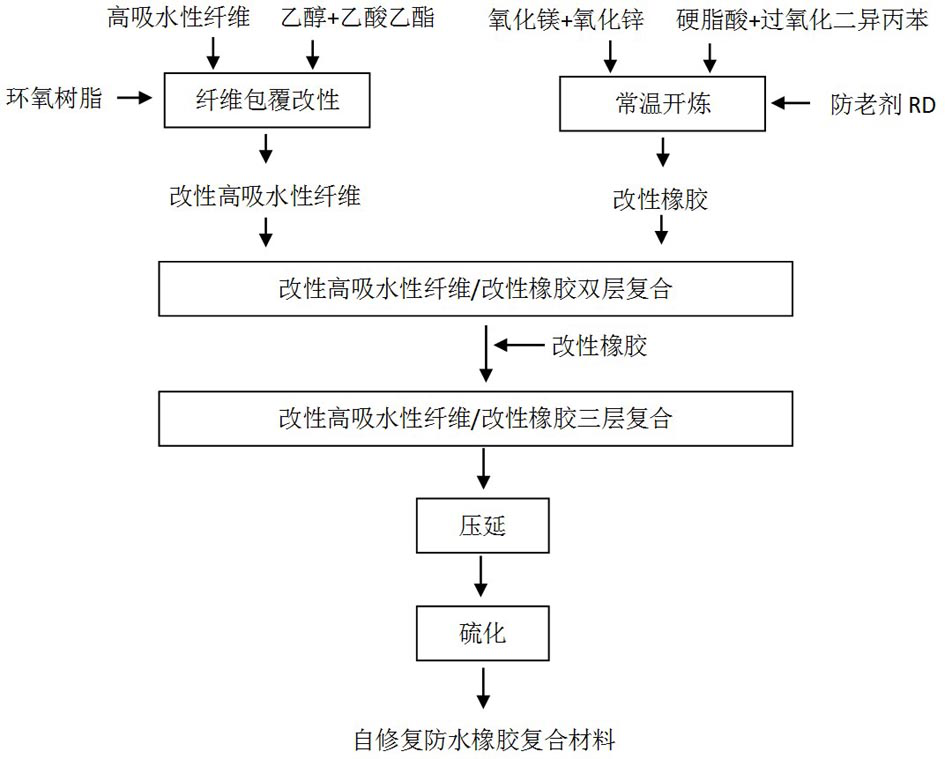

[0041] Embodiment 1: see attached figure 1 Shown, the preparation of polymer self-healing waterproof material.

[0042] Add 10 g of ethyl acetate and 30 g of absolute ethanol into a 500 ml container, and stir evenly. The epoxy resin was heated to a flowable state, and 40 g was slowly dropped into the container with a dropper, and vigorously stirred at room temperature. Weigh 0.2 g of superabsorbent fiber, add a small amount several times, and continue stirring vigorously for 3 hours to obtain suspension A. Weigh 100 parts of natural rubber, 1.5 parts of dicumyl peroxide, 1 part of magnesium oxide, 0.5 part of zinc oxide, 0.5 part of stearic acid, 0.5 part of anti-aging agent RD, roll several times on the open mill, and make triangle bags 3 times, mix well. Press the mixed rubber into a rubber sheet of about 1 mm on a flat vulcanizing machine, scrape the suspension A coating liquid evenly on the prepared rubber sheet, let it stand naturally and cure for several hours, and th...

Embodiment 2

[0061] Example 2: Preparation of polymer self-repairing waterproof material.

[0062] Add 10 g of ethyl acetate and 30 g of absolute ethanol into a 500 ml container, and stir evenly. Heat the epoxy resin to a flowable state, slowly add 40g dropwise with a dropper, and stir vigorously at room temperature. Weigh 0.2 g of superabsorbent fiber, add a small amount several times, and continue stirring vigorously for 3 hours to obtain suspension A. Weigh 100 parts of natural rubber, 1.5 parts of dicumyl peroxide, 1 part of magnesium oxide, 1 part of zinc oxide, 0.5 part of stearic acid, 1 part of anti-aging agent RD, roll several times on the open mill, and make triangular bags 3 times, mix well. Press the mixed rubber into a rubber sheet of about 1 mm on a flat vulcanizing machine, scrape the suspension A coating liquid evenly on the prepared rubber sheet, let it stand naturally and cure for several hours, and then scrape evenly again, cover Put on another piece of rubber presser...

Embodiment 3

[0066] Example 3: Preparation of polymer self-repairing waterproof material.

[0067] Add 10 g of ethyl acetate and 30 g of absolute ethanol into a 500 ml container, and stir evenly. Heat the epoxy resin to a flowable state, slowly add 40g dropwise with a dropper, and stir vigorously at room temperature. Weigh 0.2 g of superabsorbent fiber, add a small amount several times, and continue stirring vigorously for 3 hours to obtain suspension A. Weigh 100 parts of natural rubber, 1 part of dicumyl peroxide, 1 part of magnesium oxide, 0.5 part of zinc oxide, 0.5 part of stearic acid, 0.5 part of anti-aging agent RD, roll several times on the open mill, and make triangle bags 3 times, mix well. Press the mixed rubber into a rubber sheet of about 1 mm on a flat vulcanizing machine, scrape the suspension A coating liquid evenly on the prepared rubber sheet, let it stand naturally and cure for several hours, and then scrape evenly again, cover Put on another piece of rubber presser....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com