Squeegee separating device for printing machine

A technology for separation devices and printing machines, applied to printing machines, general parts of printing machinery, printing, etc., can solve problems such as misalignment of printed patterns, poor wear resistance, and influence on production progress, and achieve the effect of avoiding printing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

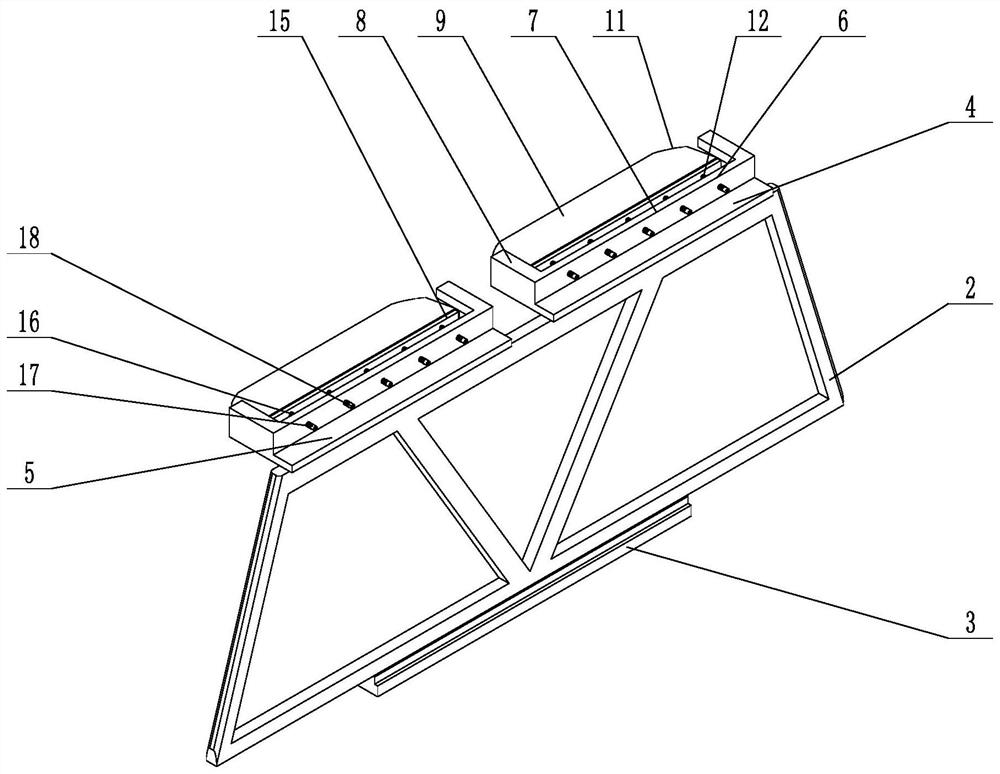

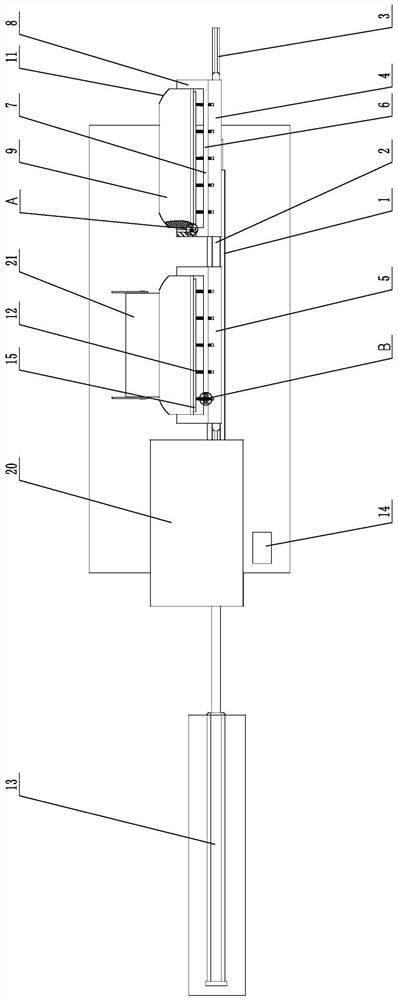

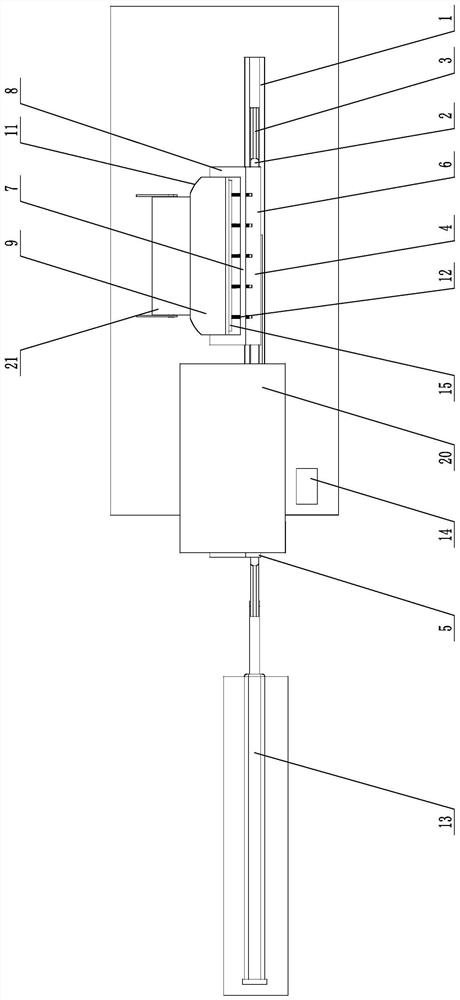

[0049] A scraper separation device for a printing machine, comprising:

[0050] The track 1 installed on the printing equipment, the track 1 is located under one side of the cylinder on the printing equipment;

[0051] The mounting frame 2, the bottom of the mounting frame 2 is a sliding part 3, the sliding part 3 is slidingly connected with the track 1, and the track 1 is used to limit the sliding part 3;

[0052] The main installation position 4, the main installation position 4 is located on the top side of the installation frame 2;

[0053] An auxiliary installation position 5, the auxiliary installation position 5 is located on the side of the top of the installation frame 2 away from the main installation position 4, and the main installation position and the auxiliary installation position are symmetrical on the top of the installation frame;

[0054] Scraper carrier 6, two scraper carriers 6 are provided, and the two scraper carriers 6 are respectively located in the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com