Tray box and manufacturing box thereof

A manufacturing method and technology of pallet boxes, which are applied in sustainable manufacturing/processing, rigid containers, sustainable packaging industries, etc., can solve the problems of inability to achieve mixed use, heavy weight, and cannot be used separately, so as to solve the problem of motorized mixing and matching. The effect of operation, saving purchase cost and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

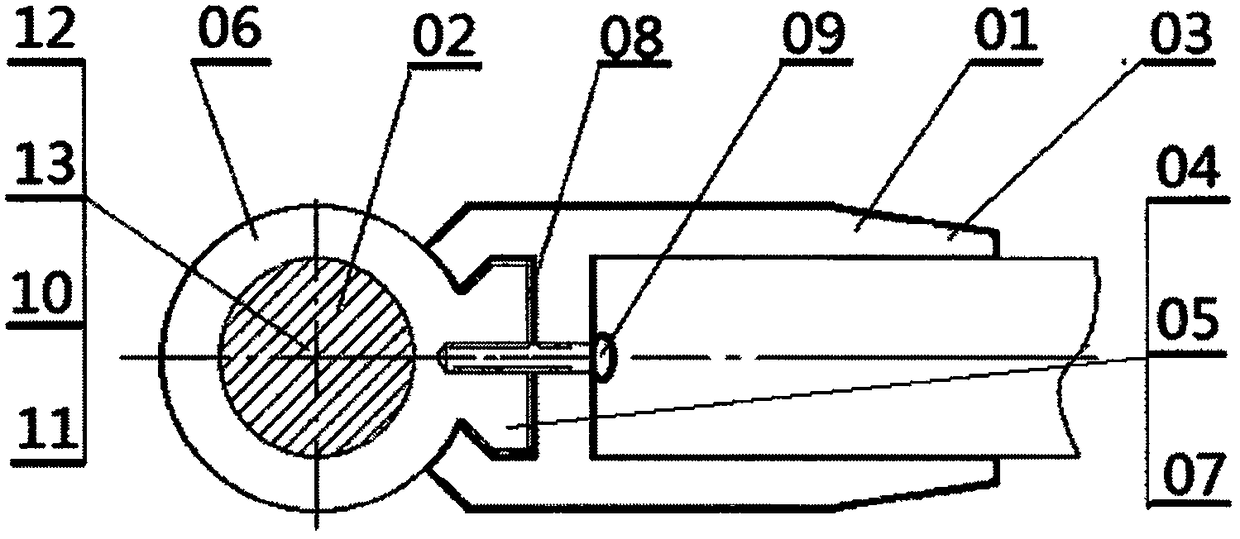

[0027] figure 1 It is a structural schematic diagram of the hinge connection assembly of the present invention. (01) in the figure is a hinge connection assembly, which has a long hinge shape in appearance and is composed of two hinge clips (03) hinged by a hinge shaft (02). The hinge clip (03) has an "H" shaped cross-section, one end is formed with a dovetail groove (04), and multiple sections of hinge buttons (05) are arranged equidistantly in the groove. The hinge button (05) is formed with a dovetail (07) on the side wall of the circular pipe section (06), the dovetail (07) is matched with the dovetail groove (04), and the adhesive (08) or Set screw (09) implements positioning connection to it, and in the shaft hole (10) of the last section hinge button (05), nut (11) is provided with. Described hinge shaft (02), outward appearance is elongated cylindrical shape, and its one end is shaped on screw thread (12), and the other end is shaped on screwdriver groove (13). The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com