Anti-vibration locking bolt pair

A bolt pair and external thread technology, which is applied in the field of fastener manufacturing, can solve the problems of low reliability and poor anti-loosening effect, and achieve the effect of simple structure, avoiding self-loosening, and preventing self-reversing and loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

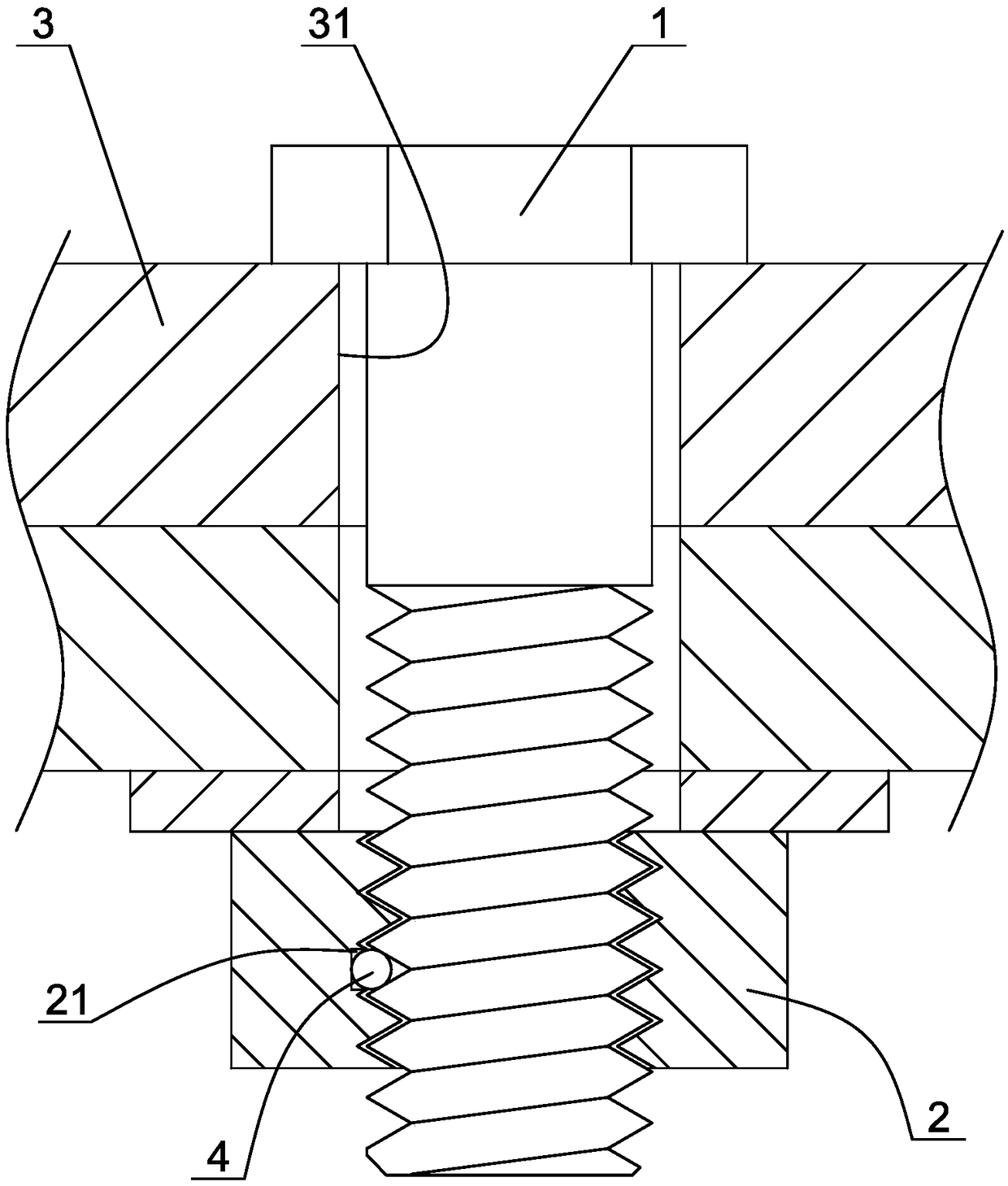

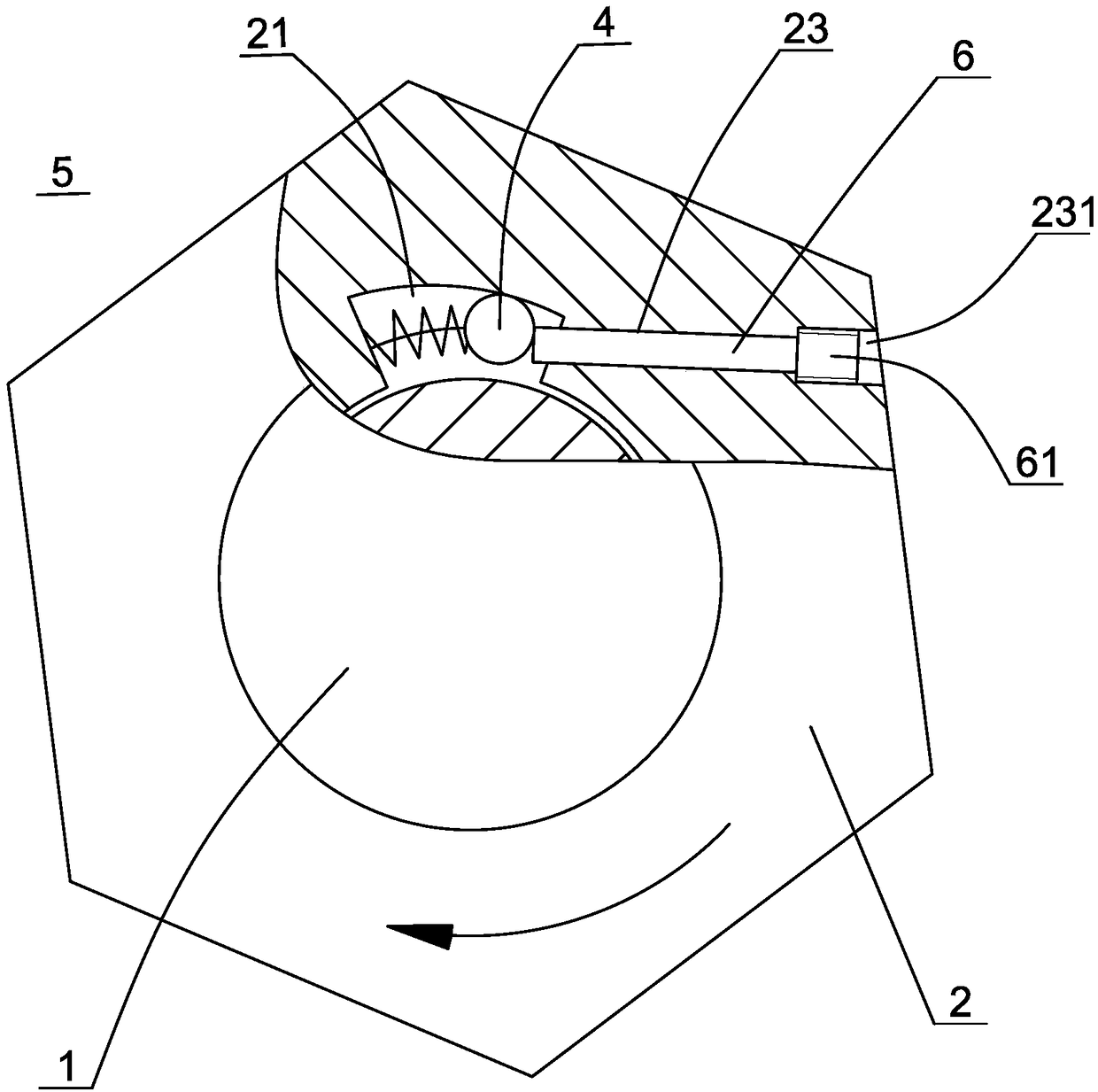

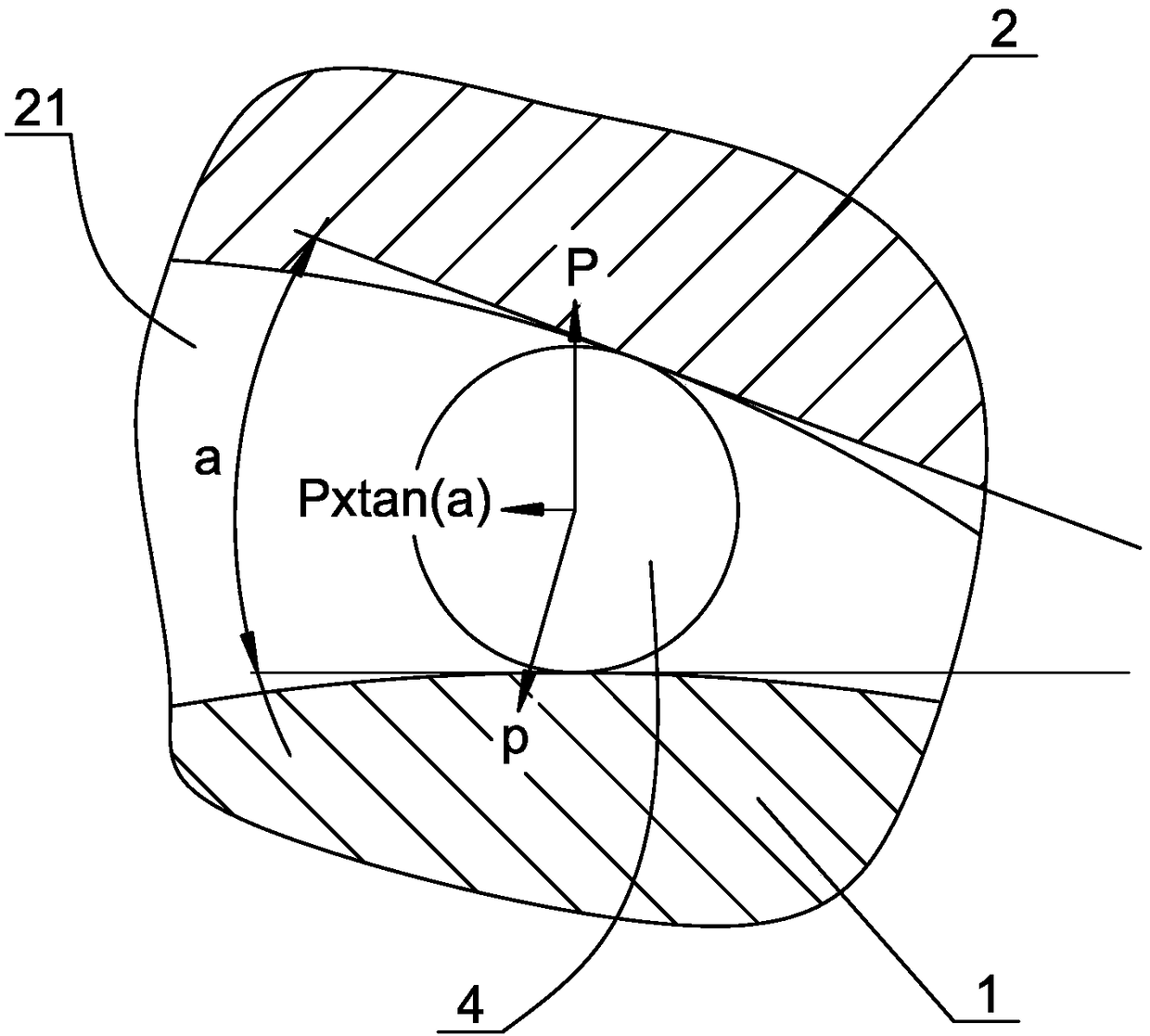

[0031] like figure 1 , figure 2 As shown, an anti-seismic never-loosening bolt pair is mainly suitable for the connection and fixation of at least two parts, including the first connecting piece 1 with external threads and the second connecting piece 2 with internal threads. Of course, when necessary Corresponding bolt through holes 31 should be provided on the connected parts 3 . In this way, the fixed connection between the parts can be realized by screwing the tail end of the first connecting part through the bolt through hole of the part and screwing the second connecting part. Similar to the prior art, we can also sleeve the gasket between the second connecting member and the part surface on the first connecting member. In addition, we need to set an overrunning clutch structure between the first connecting part and the second connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com