Thickness measuring system for inner wall anticorrosive coating of small diameter pipe

A technology of anti-corrosion coating and thickness measurement, applied in the direction of electric/magnetic thickness measurement, measuring device, electromagnetic measuring device, etc., can solve the problems of battery energy limitation, inability to detect long-distance pipelines, etc., achieve high data processing accuracy and reduce data The effect of communication distance and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

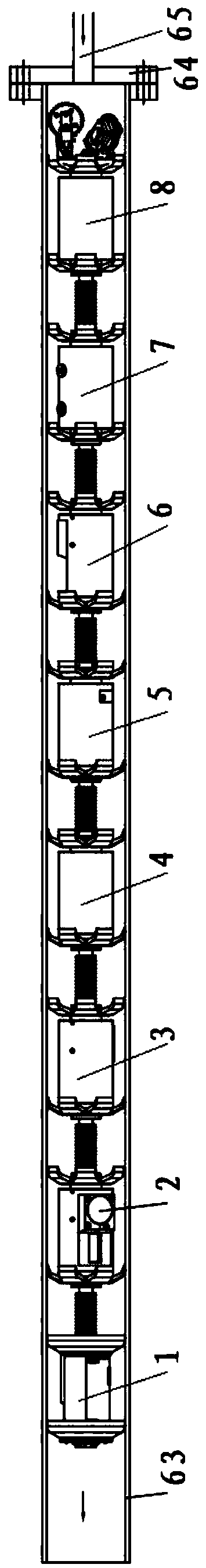

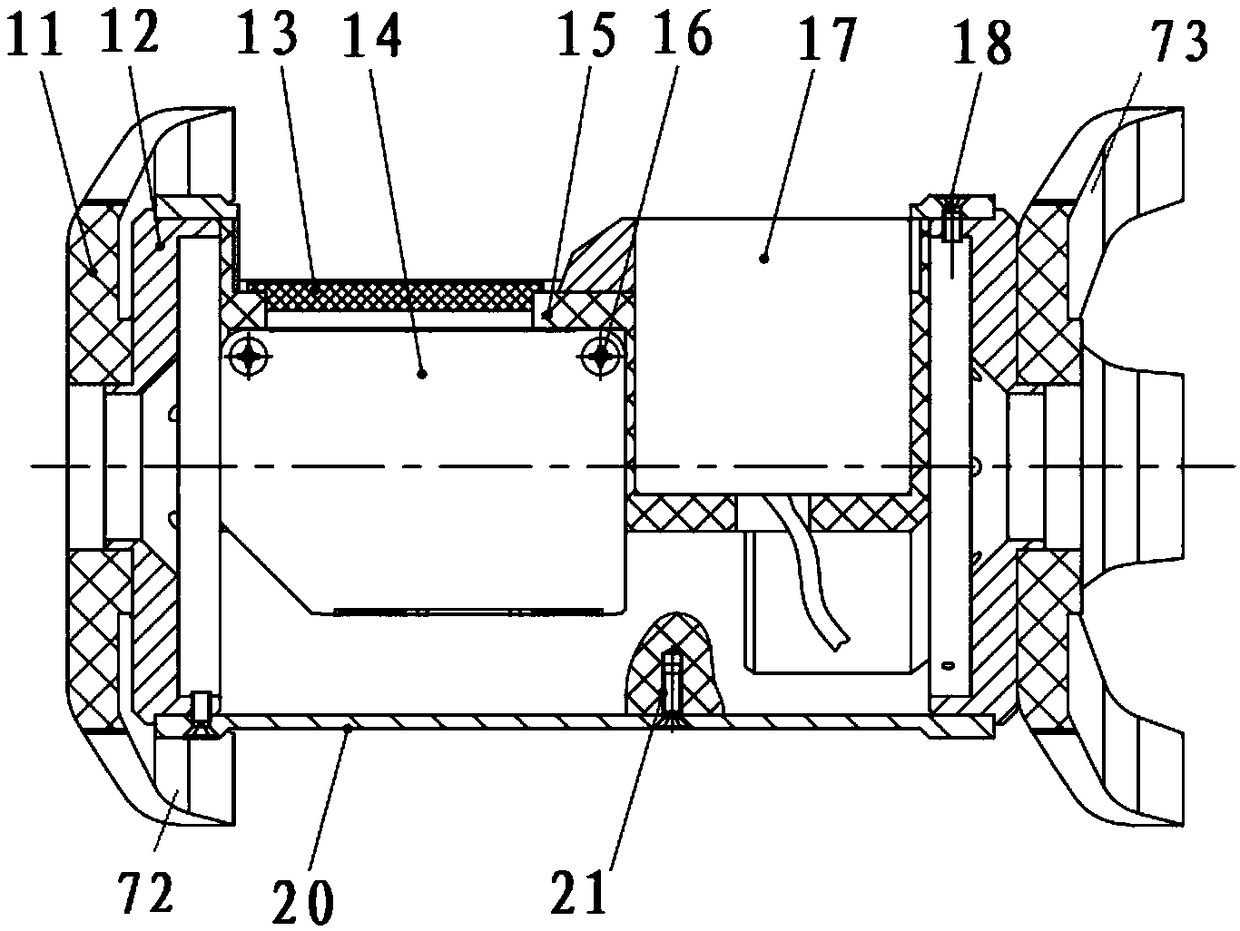

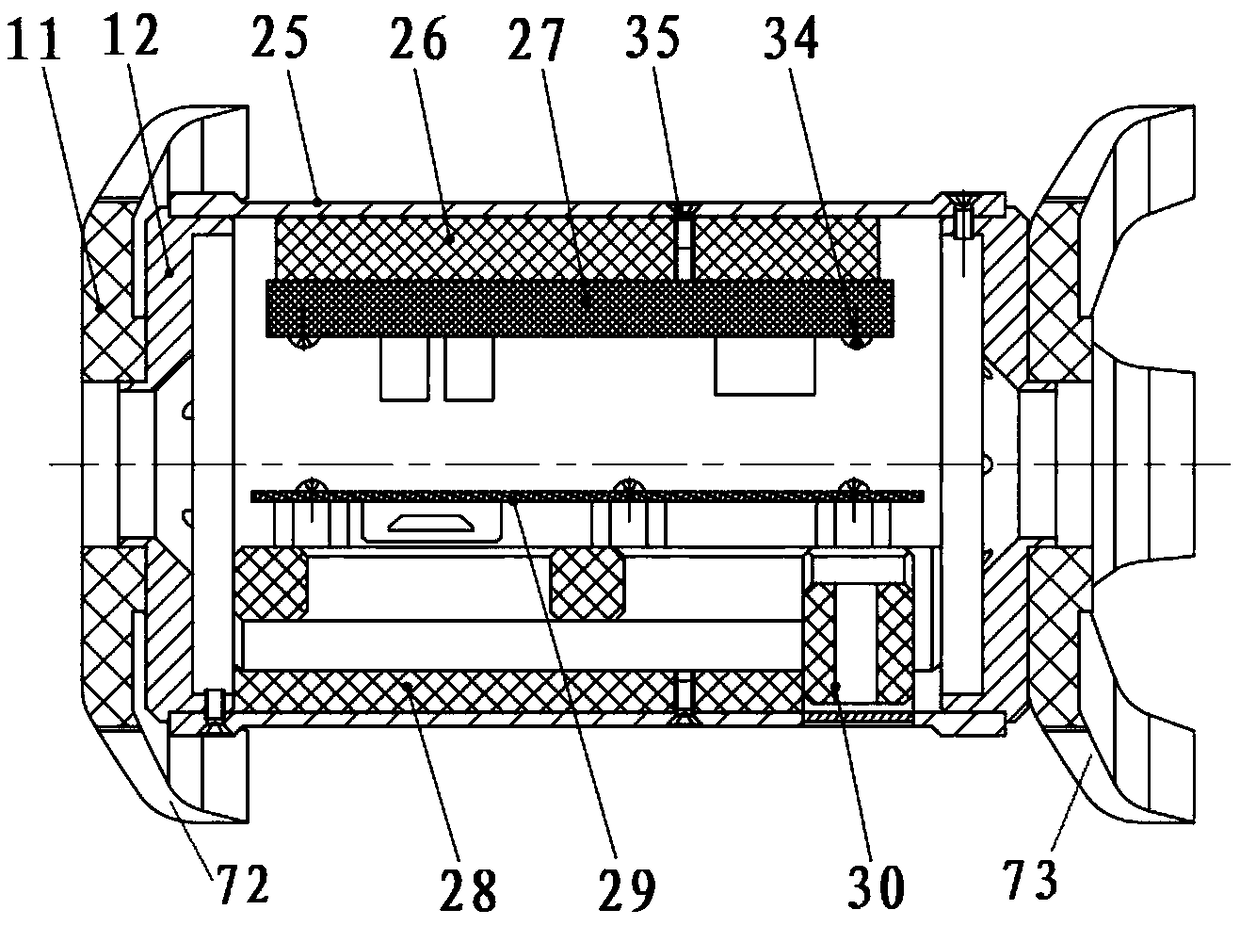

[0060] Such as figure 1 , figure 2 , Figure 8 with Picture 9 As shown, the present invention includes a first measurement vehicle 1, a second measurement vehicle 2, a first signal processing vehicle 3, a second signal processing vehicle 4, and a third measurement vehicle that are coaxially connected in the small-diameter pipe 63 from front to back. Car 5, power conversion car 6, battery car 7, and electromagnetic positioning car 8. The two adjacent car bodies are connected by a hose 9. The electromagnetic positioning car 8 is provided with a mileage metering mechanism 10 at one end away from the battery car 7. A flange 64 is installed on the input port of the caliber pipe 63. One end of the flange 64 away from the small-caliber pipe 63 is equipped with a high-pressure air pipe 65 connected to the small-caliber pipe 63. The first measuring vehicle 1, the second measuring vehicle 2 and The third measuring vehicle 5 includes a hollow structure measuring vehicle body 20 and a sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com