Method for detecting thickness of non-metallic coating on inner wall of small-aperture long-distance pipeline

A non-metallic coating, thickness detection technology, applied in the direction of electric/magnetic thickness measurement, pipe components, special pipes, etc., can solve problems such as inability to detect long-distance pipelines, battery energy limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

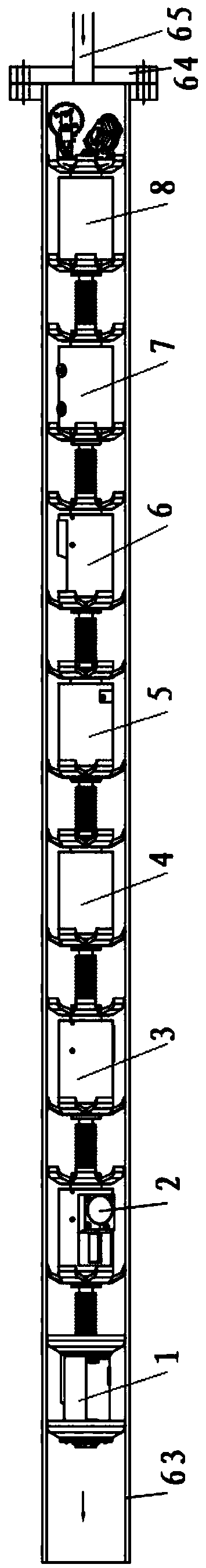

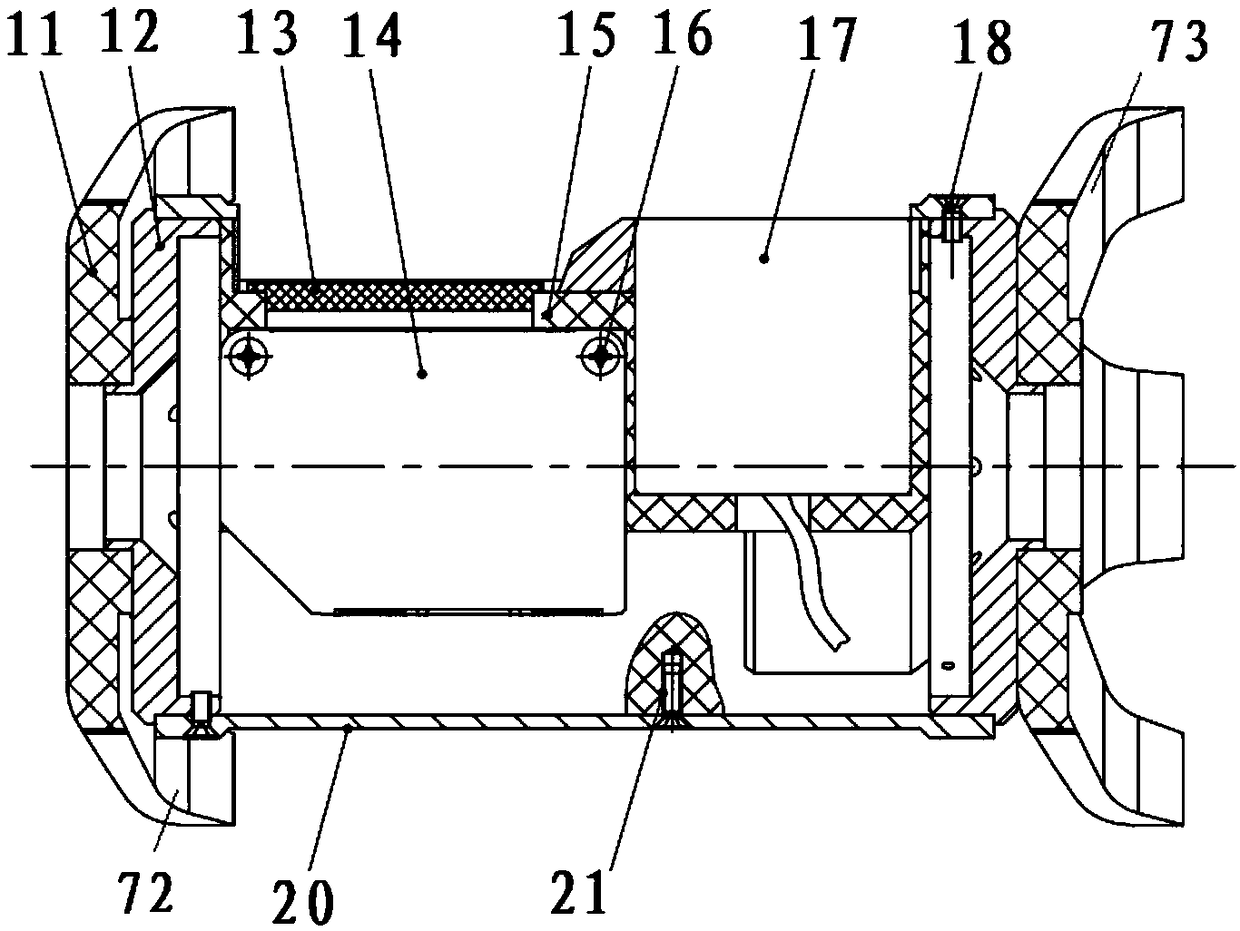

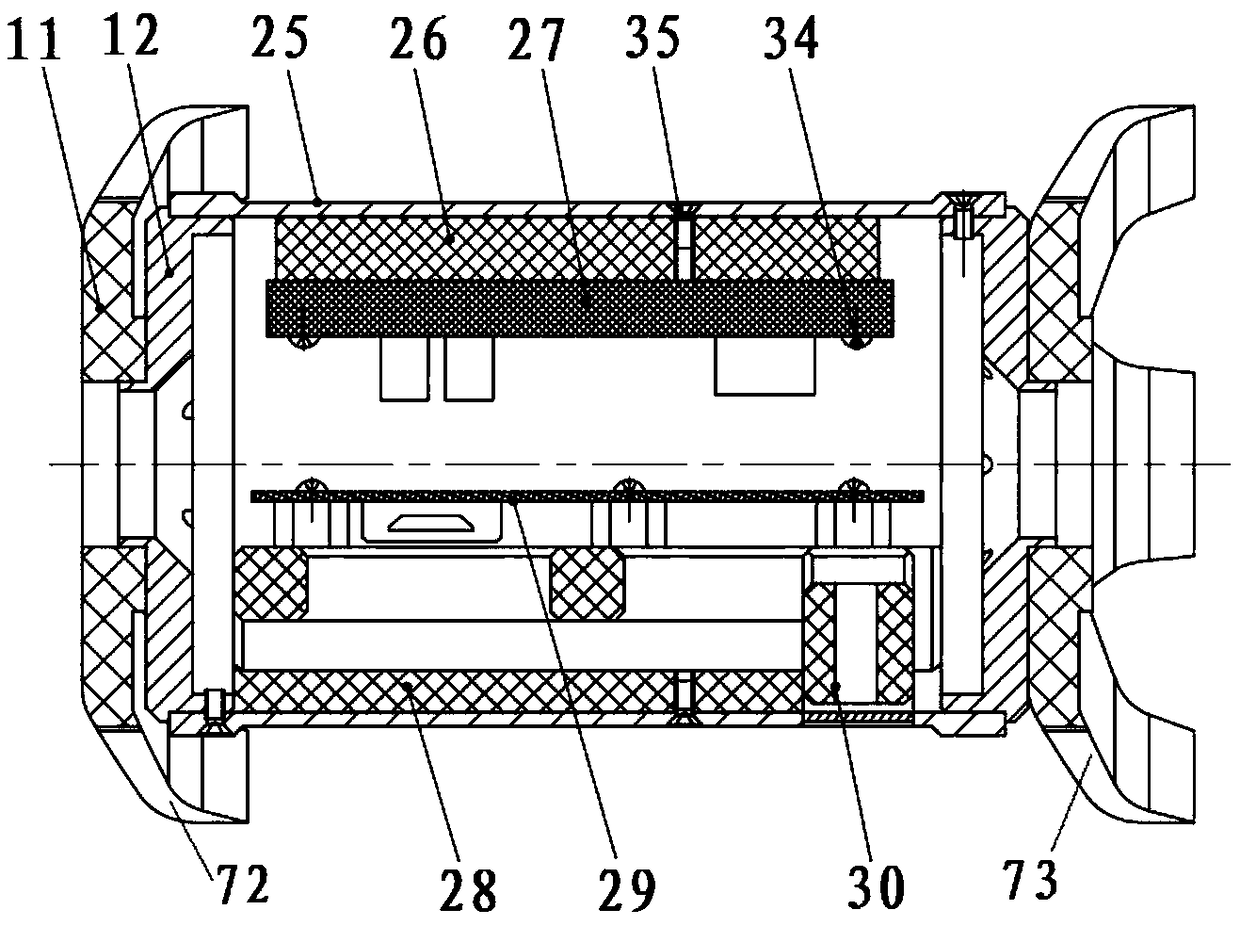

[0078] Such as figure 1 , figure 2 , Figure 8 to Figure 11 As shown, the method for detecting the thickness of the non-metallic coating on the inner wall of a small-diameter long-distance pipeline of the present invention uses a small-diameter long-distance pipeline inner wall non-metallic coating thickness detection system to detect the thickness of the small-diameter pipeline 63, and the small-diameter long-distance pipeline The non-metallic coating thickness detection system on the inner wall includes a first measuring vehicle 1, a second measuring vehicle 2, a first signal processing vehicle 3, a second signal processing vehicle 4, The third measuring car 5, the power conversion car 6, the battery car 7 and the electromagnetic positioning car 8, the two adjacent car bodies are connected by a hose 9, and the end of the electromagnetic positioning car 8 away from the battery car 7 is provided with a mileage measuring mechanism 10. A flange 64 is installed on the input po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com