Testing device and testing method of high-temperature mechanical properties of sheet glass

A flat glass, high-temperature mechanics technology, used in measuring devices, using stable tension/pressure to test the strength of materials, scientific instruments, etc., can solve the problems of cumbersome data reading and processing, large errors, and high requirements for round hole processing accuracy , to achieve the effect of fast test speed, strong function and large test temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

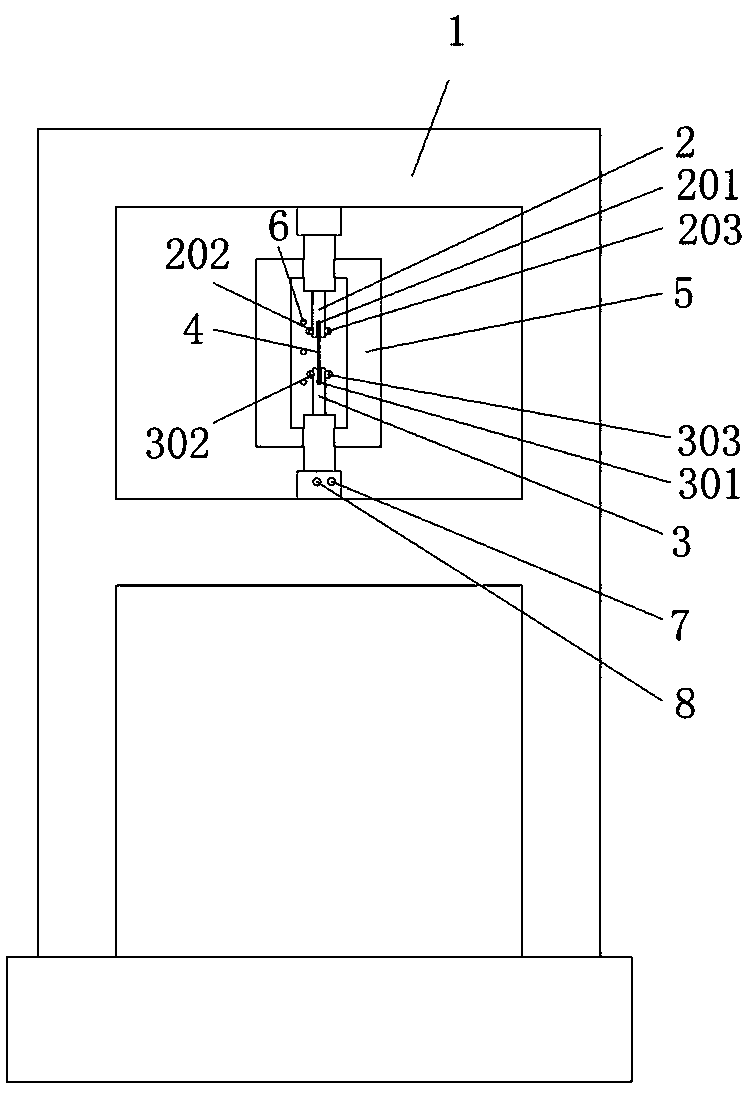

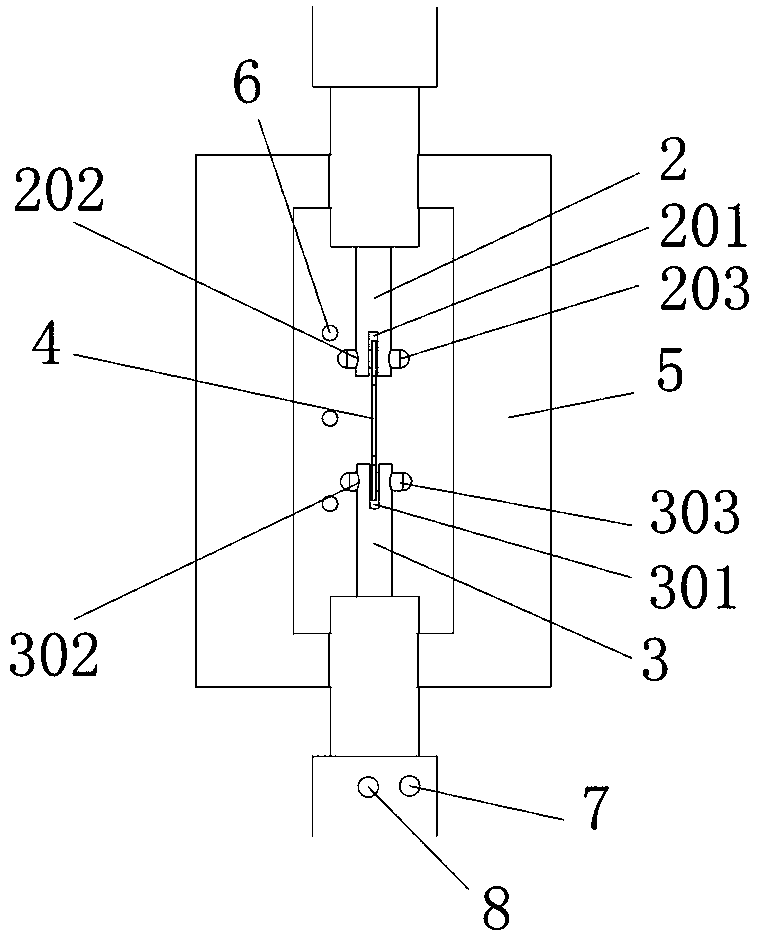

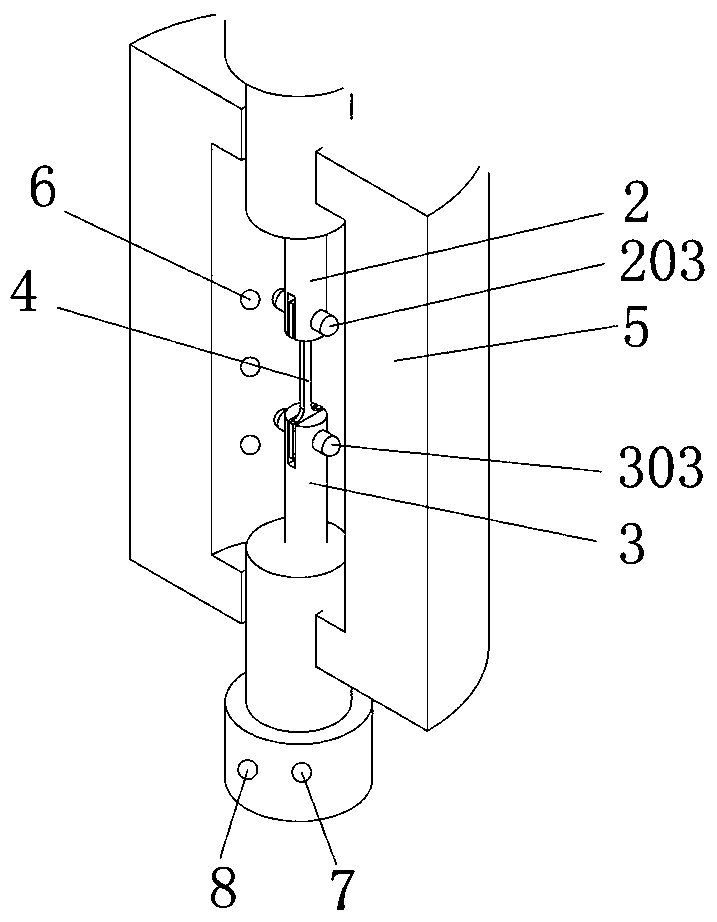

[0023] In Embodiment 1 of the present invention, the high-temperature mechanical performance test required for the design of the auto glass hot bending forming process; The upper part of the second clamping body 3 has a U-shaped second clamping portion 301 .

[0024] In the first embodiment of the present invention, the first positioning hole 202 is provided on the first clamping part 201, the second positioning hole 302 is provided on the second clamping part 301, and the first positioning hole 202 A first positioning pin 203 is provided, and a second positioning pin 303 is provided at the second positioning hole 302; preferably, in order to increase the force contact area, the first positioning pin 203 and the second positioning pin 303 can be changed to non-standard A part with a rectangular cross-section.

[0025] In Embodiment 1 of the present invention, the applicable flat glass sample 4 has a thickness of 2 mm to 3.5 mm, and a test temperature of 500°C to 750°C, which ...

Embodiment 2

[0028] In the second embodiment of the present invention, when designing the heating and softening process of automobile glass, the high-temperature mechanical performance test required; the lower part of the first clip body 2 is provided with a first wedge-shaped installation groove 204, and the second clip body 3 is provided with a second wedge-shaped mounting groove 304.

[0029] In Example 2 of the present invention, the applicable flat glass sample 4 has a thickness of 5 mm to 15 mm, and the test temperature is 300°C to 600°C. Since the tested flat glass sample 4 is relatively thick, in order to avoid stress concentration, it is necessary to increase the contact area , the test temperature is near the softening temperature of flat glass.

[0030] In the second embodiment of the present invention, a plate glass sample 4 with a thickness of 8mm is selected, and the test temperature is determined to be 500°C. The upper part of the plate glass sample 4 has a first wedge-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com