Method for evaluating early-stage freezing resistance of concrete through maturity

A concrete and maturity technology, applied in flow characteristics, measuring devices, instruments, etc., can solve the problems of difficulty in correctly grasping the mechanical properties of concrete, the influence of winter construction progress, and difficulty in ensuring construction quality control, etc., to achieve a wide range of applications and simple steps , flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

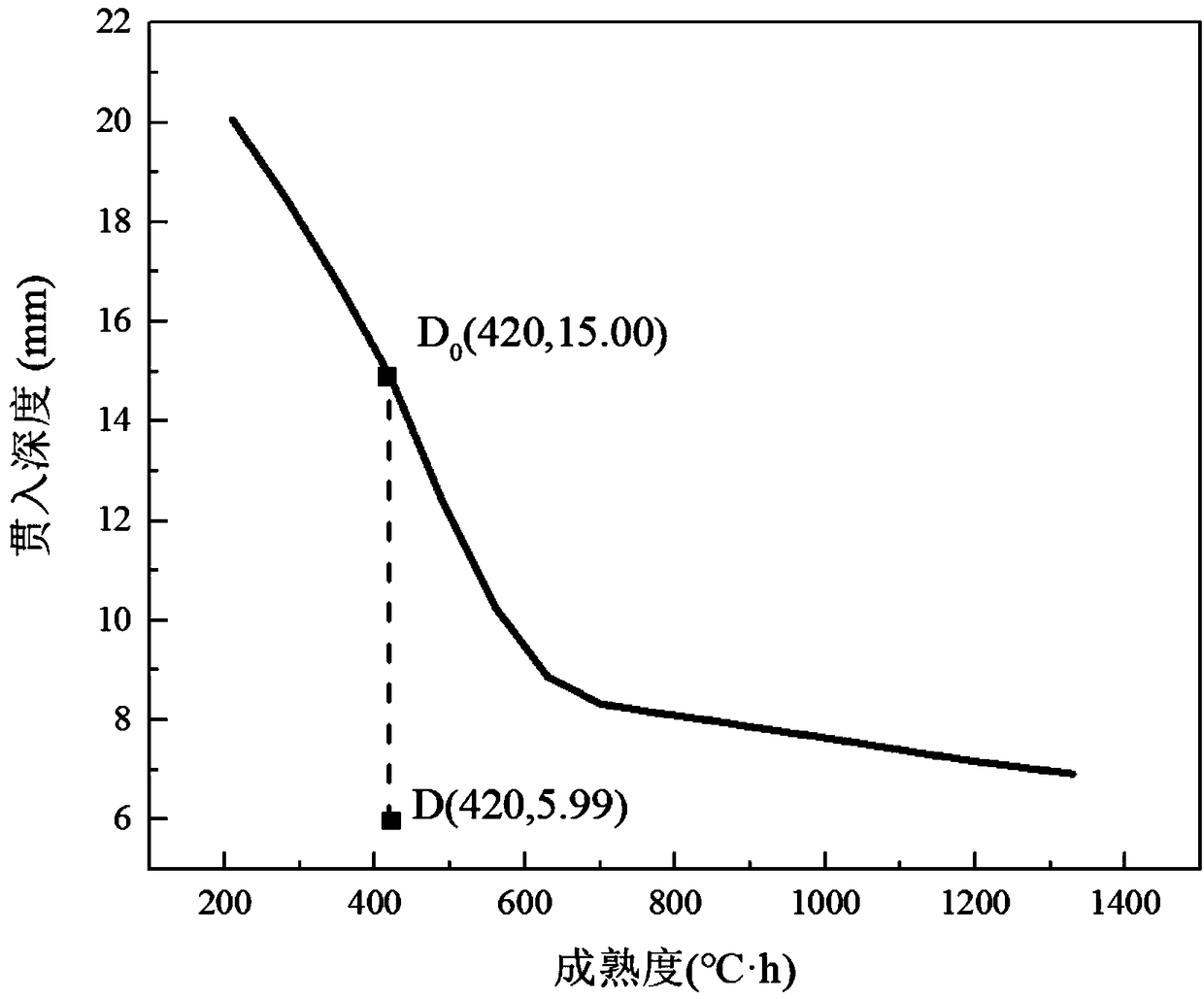

[0024] Specific implementation mode one: combine figure 1 Describe this implementation mode, including:

[0025] Determine the concrete project to be evaluated, pre-embed the temperature sensor in the concrete project to collect temperature data, determine the test age and establish the relationship curve between the penetration depth and maturity of the concrete under standard curing conditions according to the test age, and the test age is a certain time The period, specifically refers to a period of time after the pouring of the concrete project. It can be set according to specific needs. Usually, the time period setting range is selected within one month after the concrete project is formed, that is, the early stage of concrete. When the concrete When the concrete in the project is cured to the test age, the frost damage degree detection and maturity calculation are carried out at the same time. The actual penetration depth is obtained through the frost damage degree detec...

specific Embodiment approach 2

[0037] Specific implementation mode two: combination figure 1 Describe this embodiment, this embodiment includes following four steps,

[0038] Step 1: First, for winter construction or concrete projects in cold areas, pre-embed a temperature sensor during concrete construction and connect a temperature recorder to record the internal temperature of the concrete in real time and determine the test age.

[0039] Step 2: Next, under standard curing conditions, according to the test age, establish the relationship curve between concrete penetration depth and maturity.

[0040]Step 3: When the concrete is cured to the test age and it is necessary to detect the degree of concrete frost damage, the penetrometer can be used to inject steel nails on the concrete surface to measure the penetration depth, and obtain the penetration of the on-site concrete project under the test age Depth, and calculate the maturity corresponding to this age according to the development of the temperatu...

specific Embodiment approach 3

[0044] Specific embodiment 3: This embodiment is a further limitation of specific embodiment 1 or 2. When the concrete test block under standard maintenance is tested for penetration depth, it is penetrated every 2 hours from demoulding to the first day of forming. depth test. On the 2nd and 3rd day after molding, a penetration depth test is performed every 12 hours. From the 4th day to the 28th day after molding, a penetration depth test is performed every 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com