A Method for Evaluating the Early Freeze Performance of Concrete Using Shock Elastic Waves

An impact elasticity, concrete technology, applied in the generation of ultrasonic/sonic/infrasonic waves, the use of sonic/ultrasonic/infrasonic waves to analyze solids, the application of thermometers, etc. Influence of construction progress and other issues to ensure completeness, wide application range and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

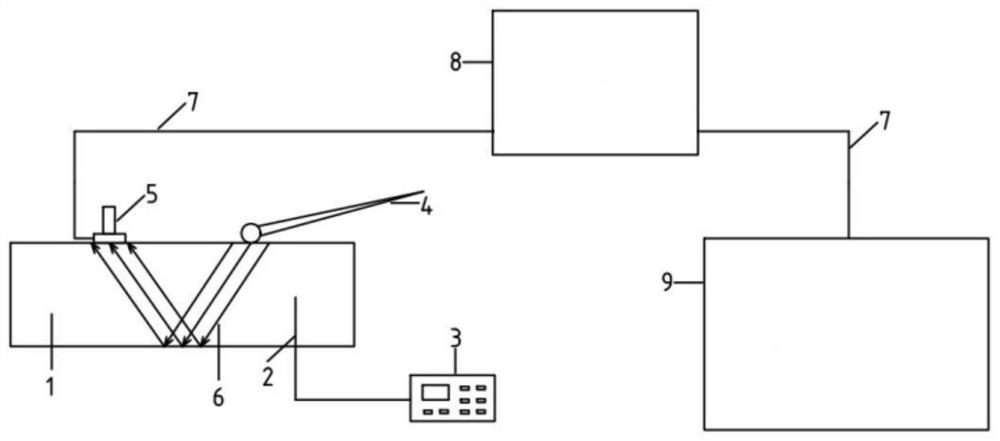

[0027] Specific implementation mode one: combine figure 1 Describe this implementation mode, including:

[0028] Determine the concrete project 1 to be evaluated, pre-embed the temperature sensor 2 in the concrete project 1 to collect temperature data, determine the test age, and establish a standard maintenance condition according to the test age, use the excitation device and the acceleration sensor 5 to complete the shock elasticity The relationship curve between wave longitudinal wave velocity and maturity, the test age is a certain period of time, specifically refers to a period of time after the concrete project 1 is poured and formed, it can be set according to specific needs, usually the time period setting range is selected in Within one month after the curing of concrete project 1, that is, the early-age stage of concrete, when the concrete in concrete project 1 is cured to the test age, the degree of frost damage and maturity calculation are carried out at the same ...

specific Embodiment approach 2

[0045] Specific implementation mode two: combination figure 1 Describe this implementation mode, this implementation mode comprises the following four steps:

[0046] Step 1: First of all, for winter construction or concrete project 1 in cold areas, pre-embed the temperature sensor 2 during concrete construction, and connect the temperature recorder 3 to record the internal temperature of the concrete in real time and determine the test age.

[0047] Step 2: Next, under standard curing conditions, the concrete with the same mix ratio is used to establish the relationship curve between longitudinal wave velocity and maturity of concrete according to the test age.

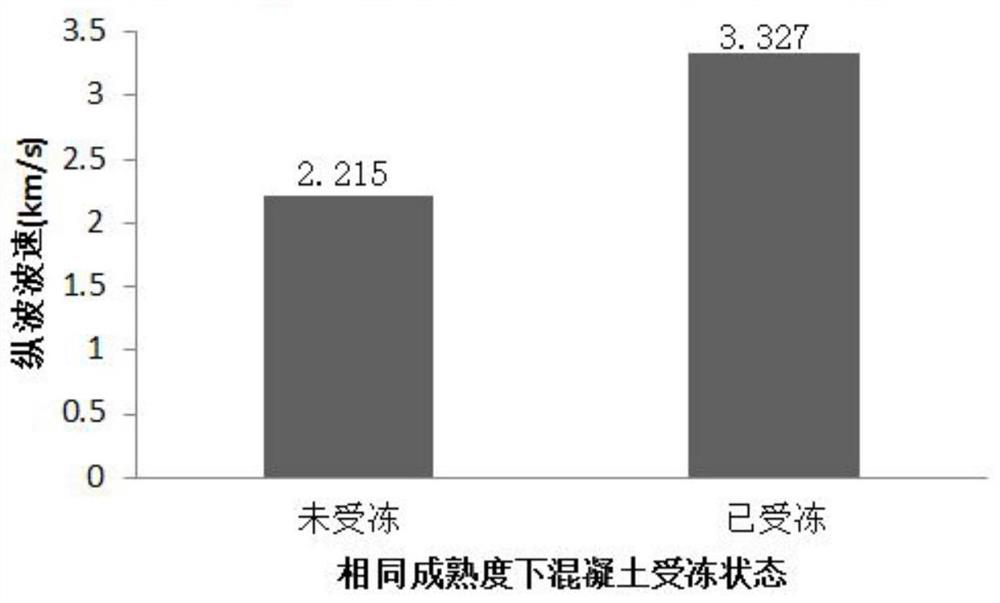

[0048] Step 3: Select the test area in the concrete project 1. When the degree of frost damage of the concrete needs to be tested after curing to the test age, the longitudinal wave velocity test can be carried out on the concrete surface with a concrete multifunctional non-destructive testing instrument to obtain th...

specific Embodiment approach 3

[0052] Embodiment 3: This embodiment is a further limitation of Embodiment 1 or 2. When the concrete test block under standard maintenance is tested for longitudinal wave velocity, the longitudinal wave velocity test is performed every 6 hours after the first day of forming. On the 2nd and 3rd day after molding, the longitudinal wave velocity test is carried out every 12 hours. From the 4th day to the 28th day after molding, the longitudinal wave velocity test is carried out every 24 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com