Printed board real-time working detection device

A technology of real-time work and detection equipment, applied in the field of testing, can solve the problems that the printed board cannot cover each working point of the printed board, and the fault or abnormal situation is difficult to locate accurately in time, so as to achieve the simple and efficient monitoring and inspection method, and the design principle Simple, feasible, and less difficult to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

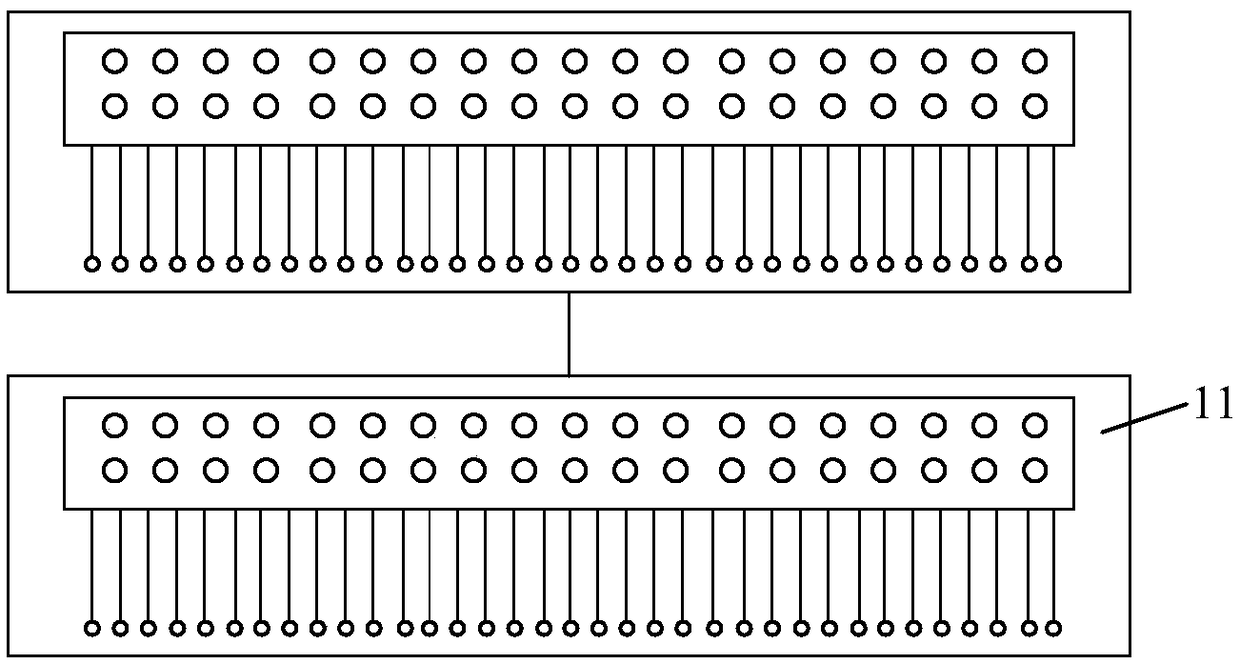

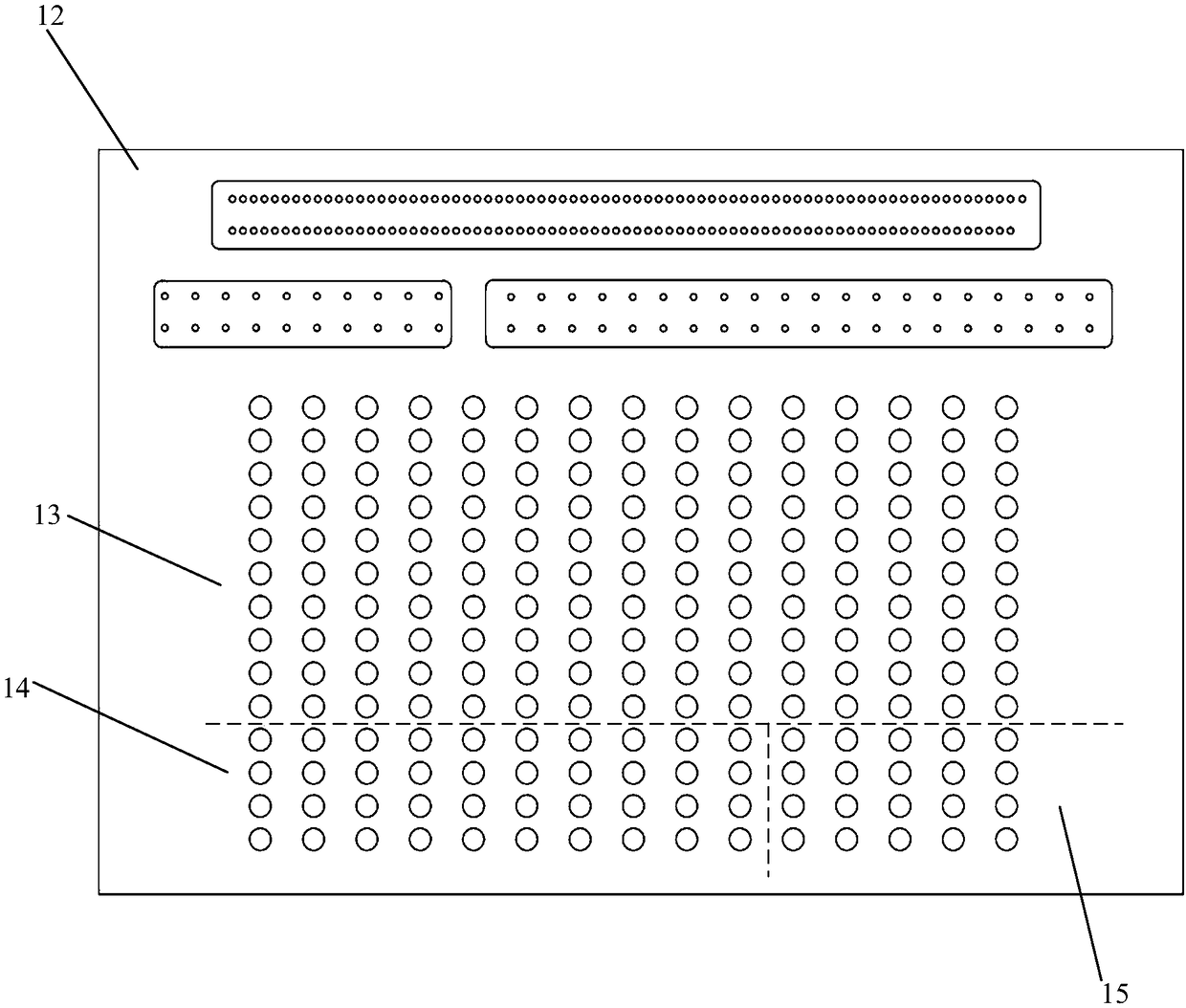

[0018] The printed board real-time work monitoring equipment proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that the drawings are all in a very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0019] The core idea of the present invention is that the printed board real-time work monitoring equipment provided by the present invention takes into account the versatility of the product interface, and can simply and conveniently perform real-time detection during the work of the printed board through methods such as eliciting signals and transition tests, providing Real-time inspection and maintenance provides a choice; printed board real-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com