Horizontal column type heat exchanger exterior dirt three-phase fluidization in-situ cleaning process

A technology of horizontal tubes and heat exchangers, which is applied in the direction of cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

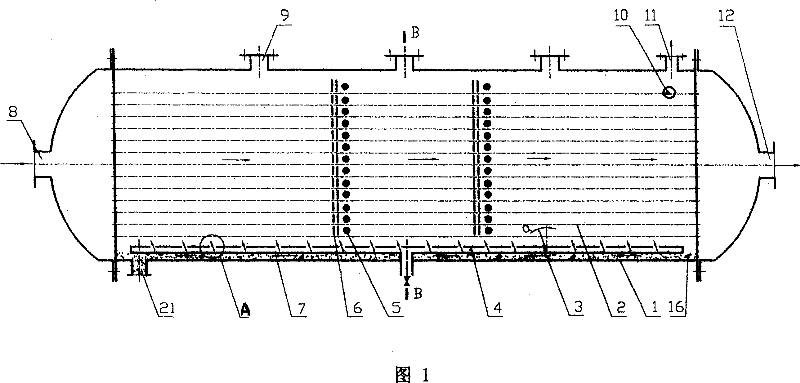

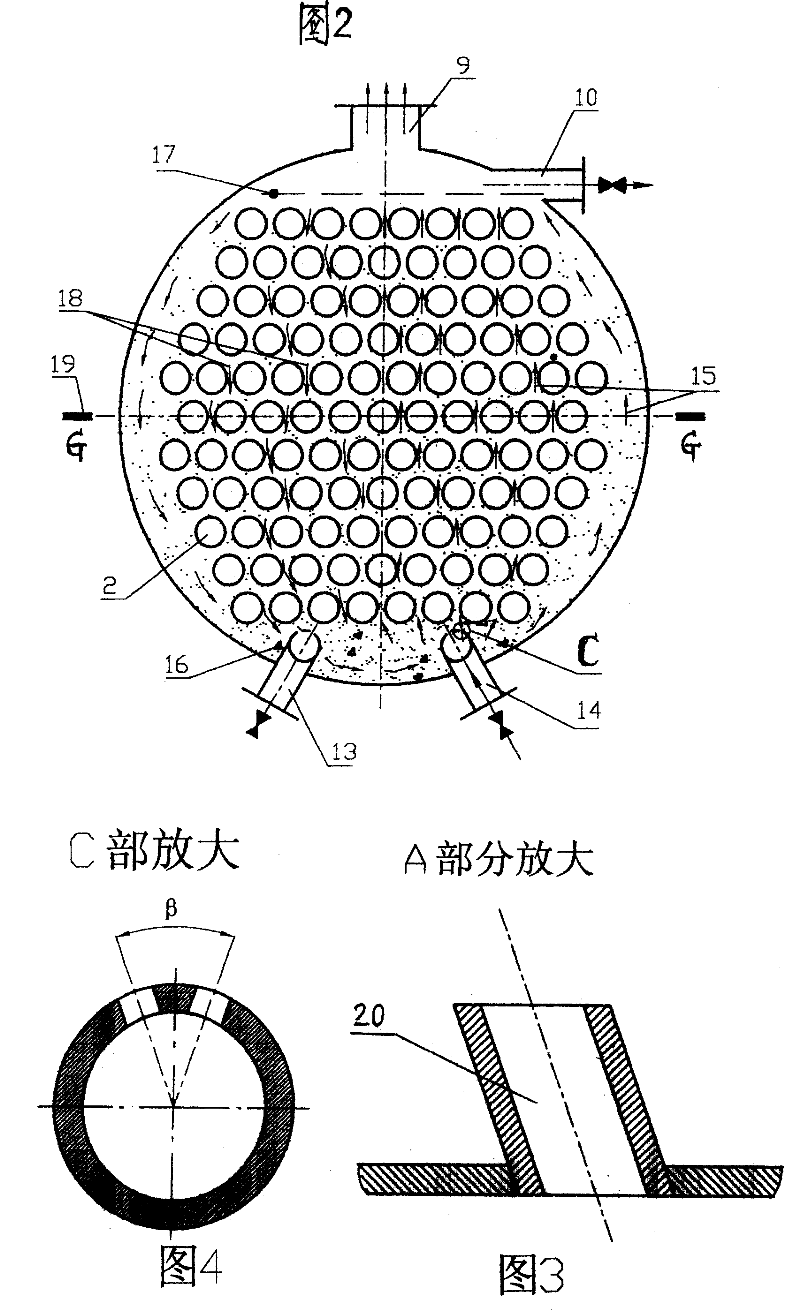

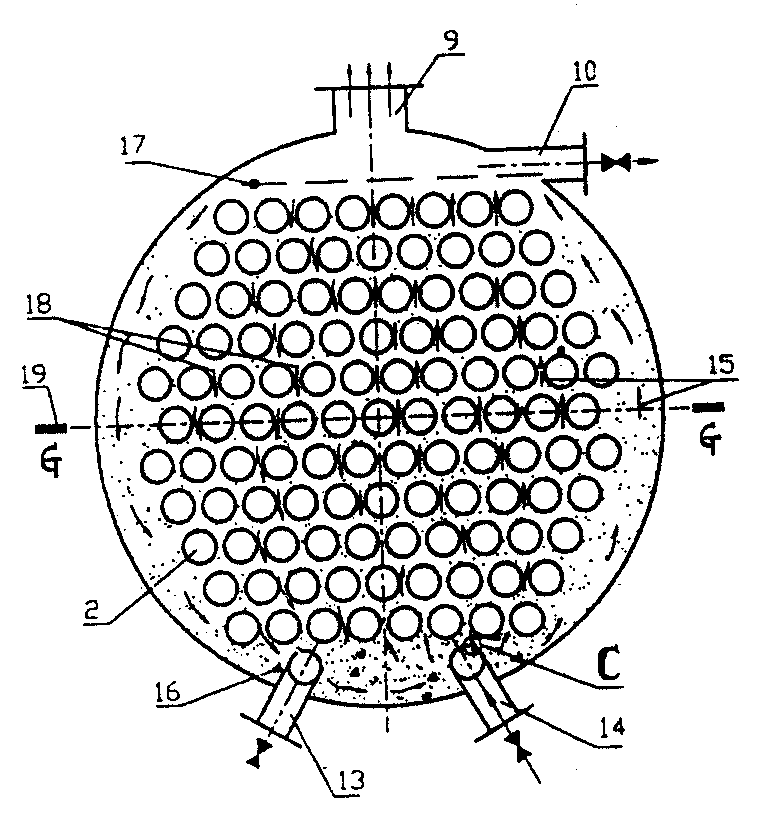

[0012] The following describes the specific implementation of the patented fluidized on-line shell-side shell-side heat exchanger in conjunction with accompanying drawings 1, 2, 3 and 4:

[0013] When cleaning the dirt outside the pipe during operation, open the right air supply valve 14, exhaust port 9 and overflow port 10 on the side of the shell, and close the liquid outlet 11 on the shell side. When the velocity of the cleaning gas at G-G19, the largest cross-section between the pipes, exceeds a certain value for the settling velocity of the particles there, the cleaning gas enters the bottom of the right half of the shell through the gas jet hole 3 or gas jet nozzle, and disperses into a large amount of steam. The upward buoyancy of the bubbles drives the shell-side liquid to move upward violently, and drives the fluidized particles 16 to flow upward 15 to the gas-liquid separation surface 17 controlled by the overflow port 10 , and the cleaning gas is separated and discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com