Horizontal column type heat exchanger exterior dirt three-phase fluidization in-situ cleaning process

A technology of horizontal tubes and heat exchanger tubes, which is applied in the field of three-phase fluidized online cleaning of dirt outside the tubes of horizontal tubes and tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

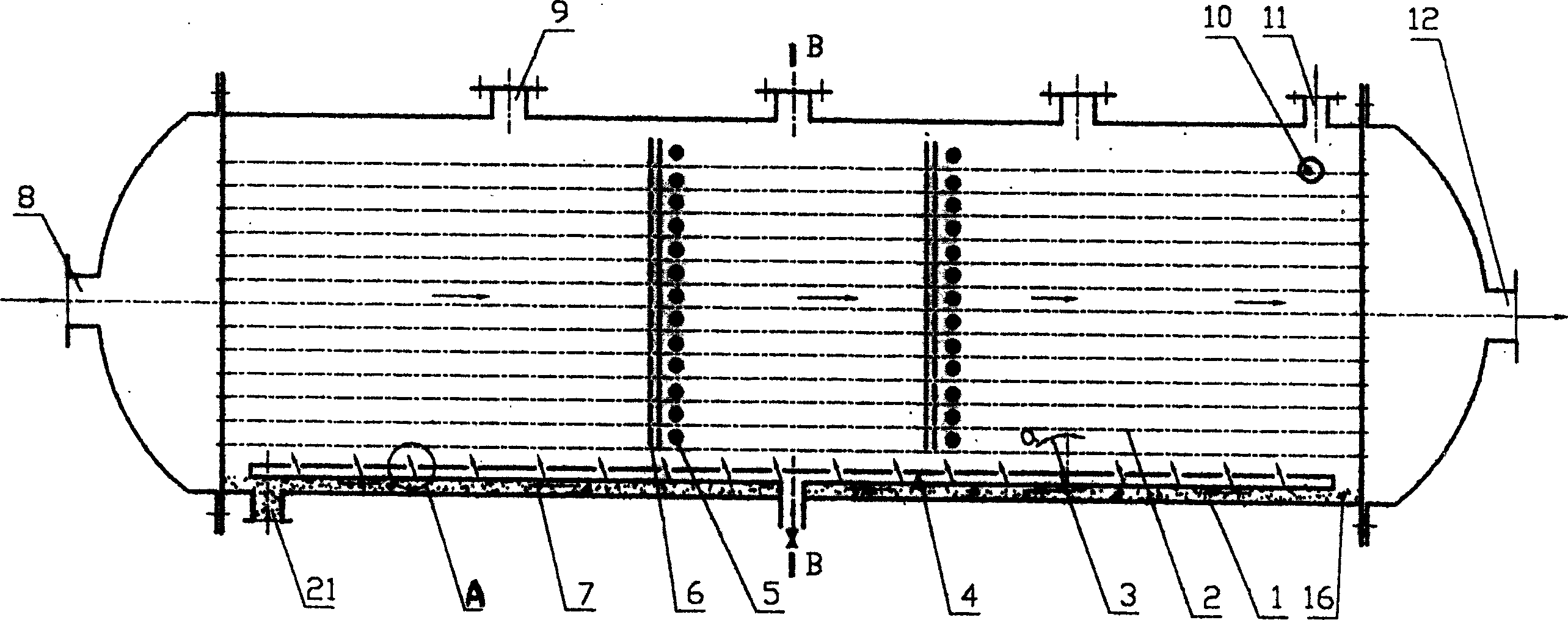

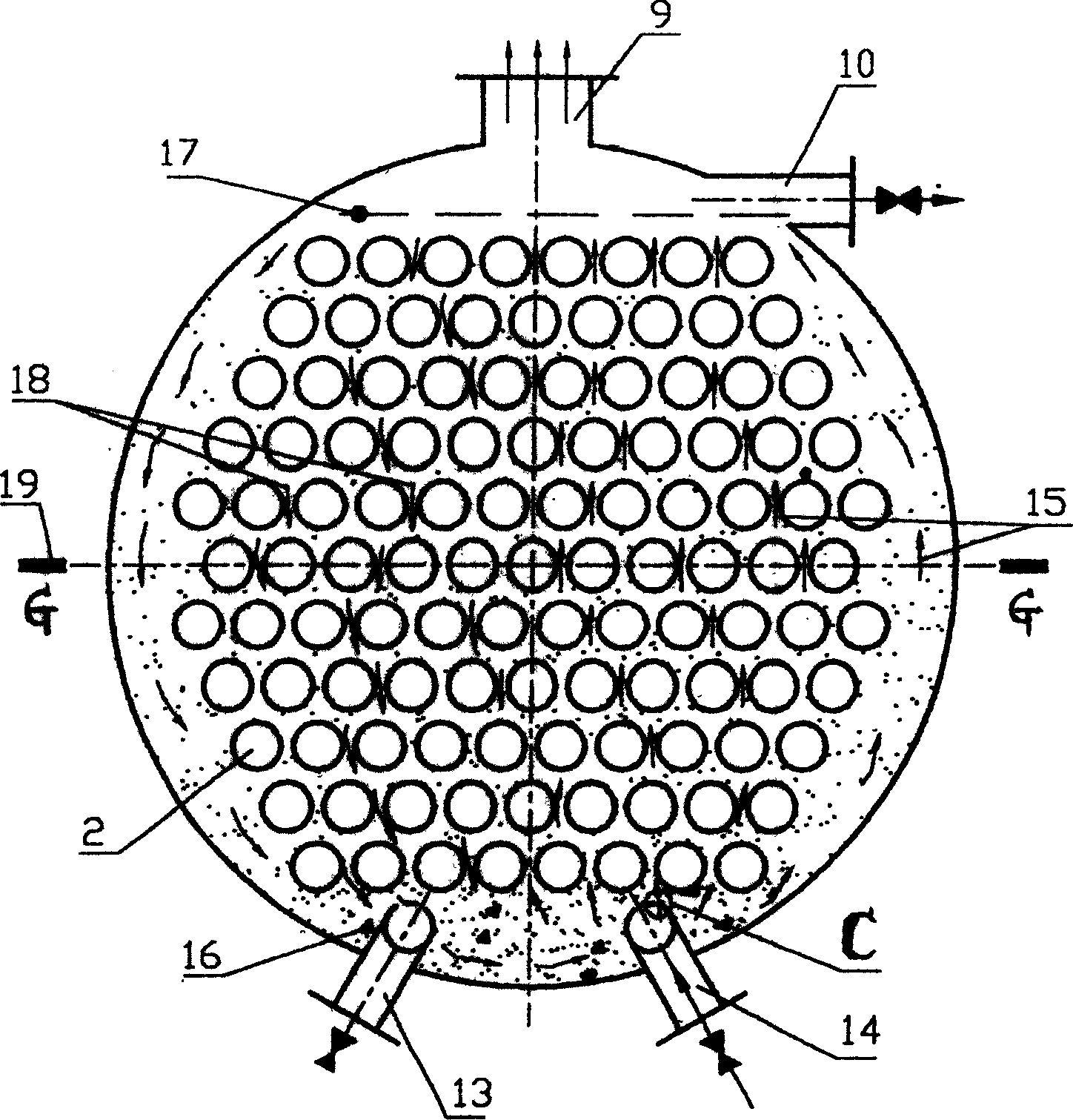

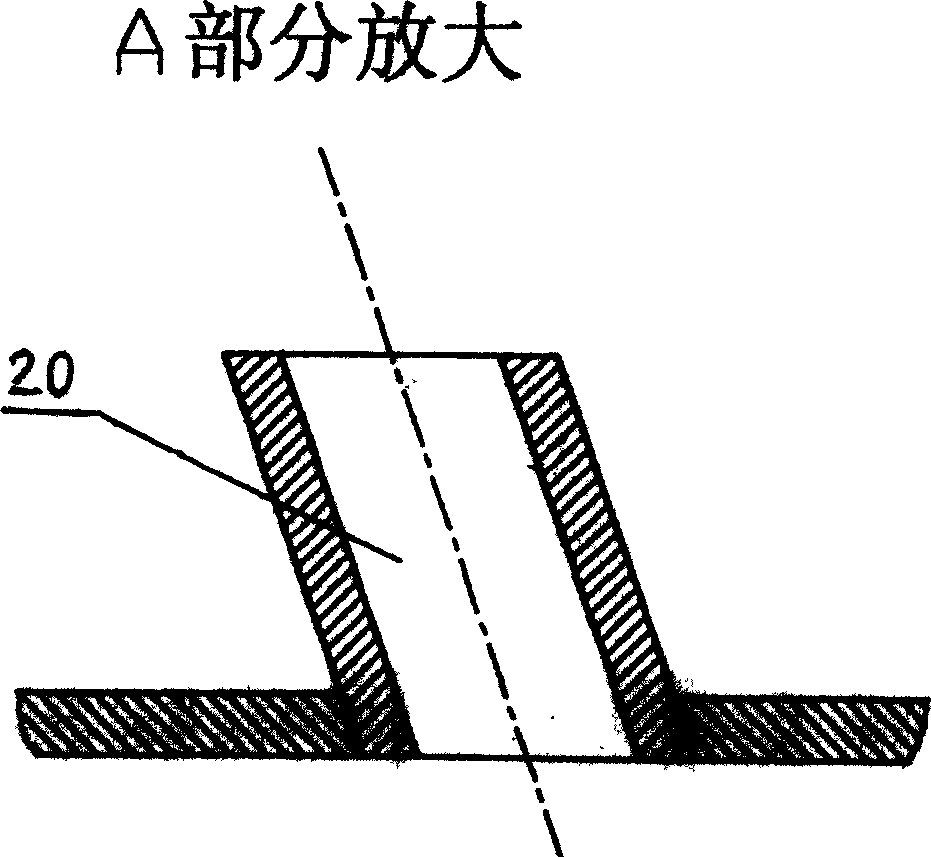

[0011] Attached to the following figure 1 , attached figure 2 , attached image 3 and attached Figure 4 Describe the specific embodiment of the patent of the present invention:

[0012] In the figure 1. Shell 2. Heat transfer tube 3. Air jet oblique hole 4. Air distribution tube 5. Baffle rod E 6. Baffle rod F 7. Particle axial circulation 8. Tube side fluid inlet 9. Exhaust port 10. Overflow port 11. Shell side liquid outlet 12. Tube side fluid outlet 13. Left half air supply valve 14. Right half air supply valve 15. Particles flow upwards 16. Fluidized particles 17. Gas-liquid separation surface 18. Circumferential direction Circulating downflow 19. Maximum section of pipe bridge G-G 20. Air jet oblique nozzle 21. Shell side liquid inlet

[0013] When cleaning the dirt outside the pipe during operation, open the right half air supply valve 14, the exhaust port 9 and the overflow port 10 on one side of the shell, and close the shell side liquid outlet 11. When the velo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com