Straightness measuring method and device, electronic equipment and storage medium

A measurement method and technology of electronic equipment, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that cannot truly reflect the real flatness, achieve the effect of automatic measurement ability and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

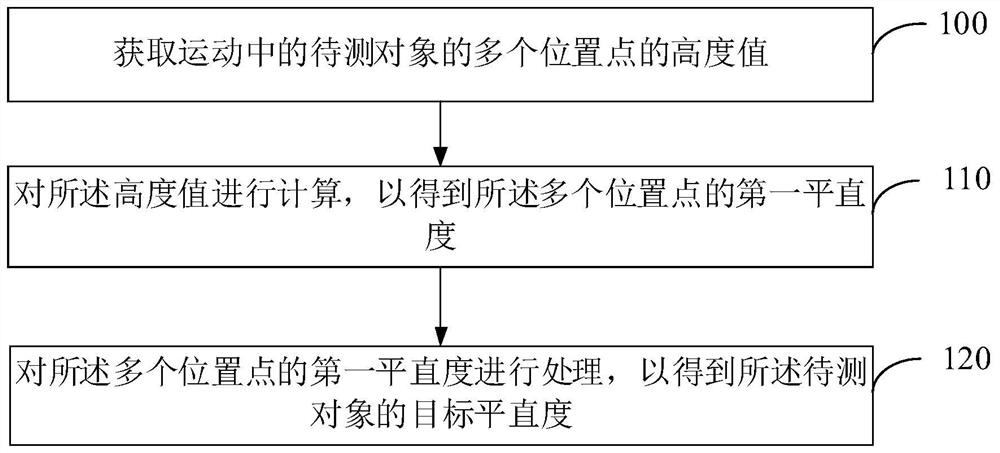

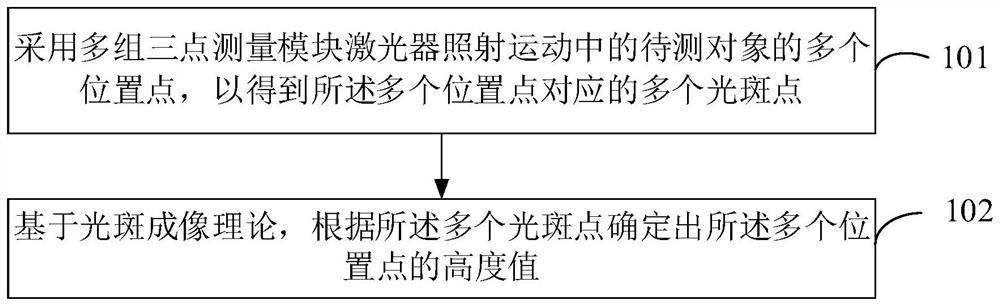

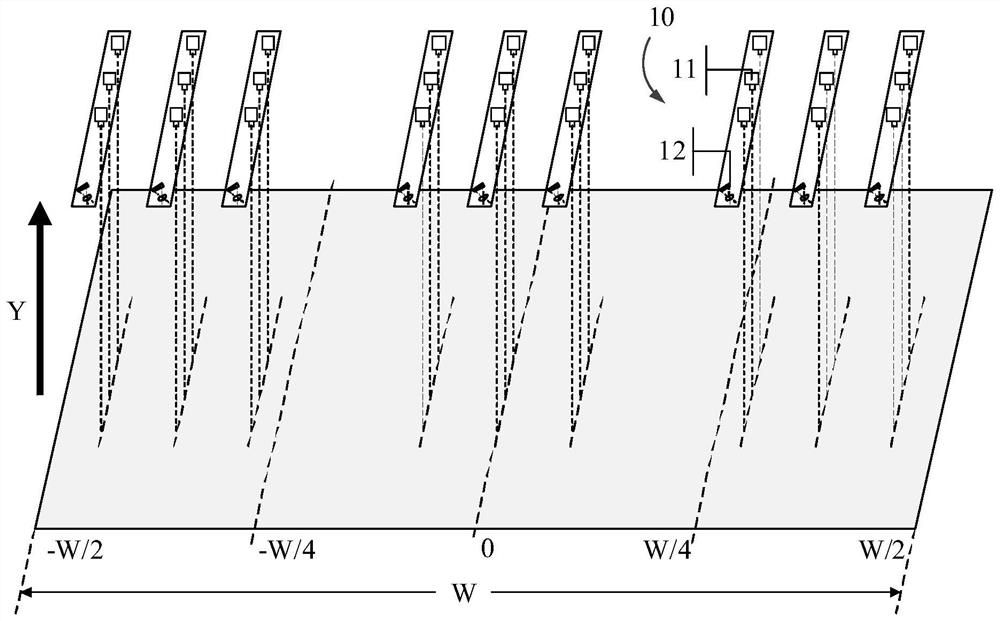

[0036] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

[0037] It should be noted that like numerals and letters denote similar items in the following figures, therefore, once an item is defined in one figure, it does not require further definition and explanation in subsequent figures. Meanwhile, in the description of the present application, the terms "first", "second" and the like are only used to distinguish descriptions, and cannot be understood as indicating or implying relative importance.

[0038] The inventor of the present application has noticed that most of the flatness detection devices currently used in China rely on imports, which are not only expensive, but also require a lot of time for maintenance and repair. Most of the domestic flatness detection devices cannot be installed and used on site. This has greatly restricted the development ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com