Water resistance load adjusting device

A technology of load regulation and water resistance, which is applied in power supply testing, motor generator testing, etc., can solve problems affecting the accuracy of electrical performance testing, complex motion adjustment mechanisms, and wear of wire insulation layers, so as to achieve fully automatic control and upgrade Continuity, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

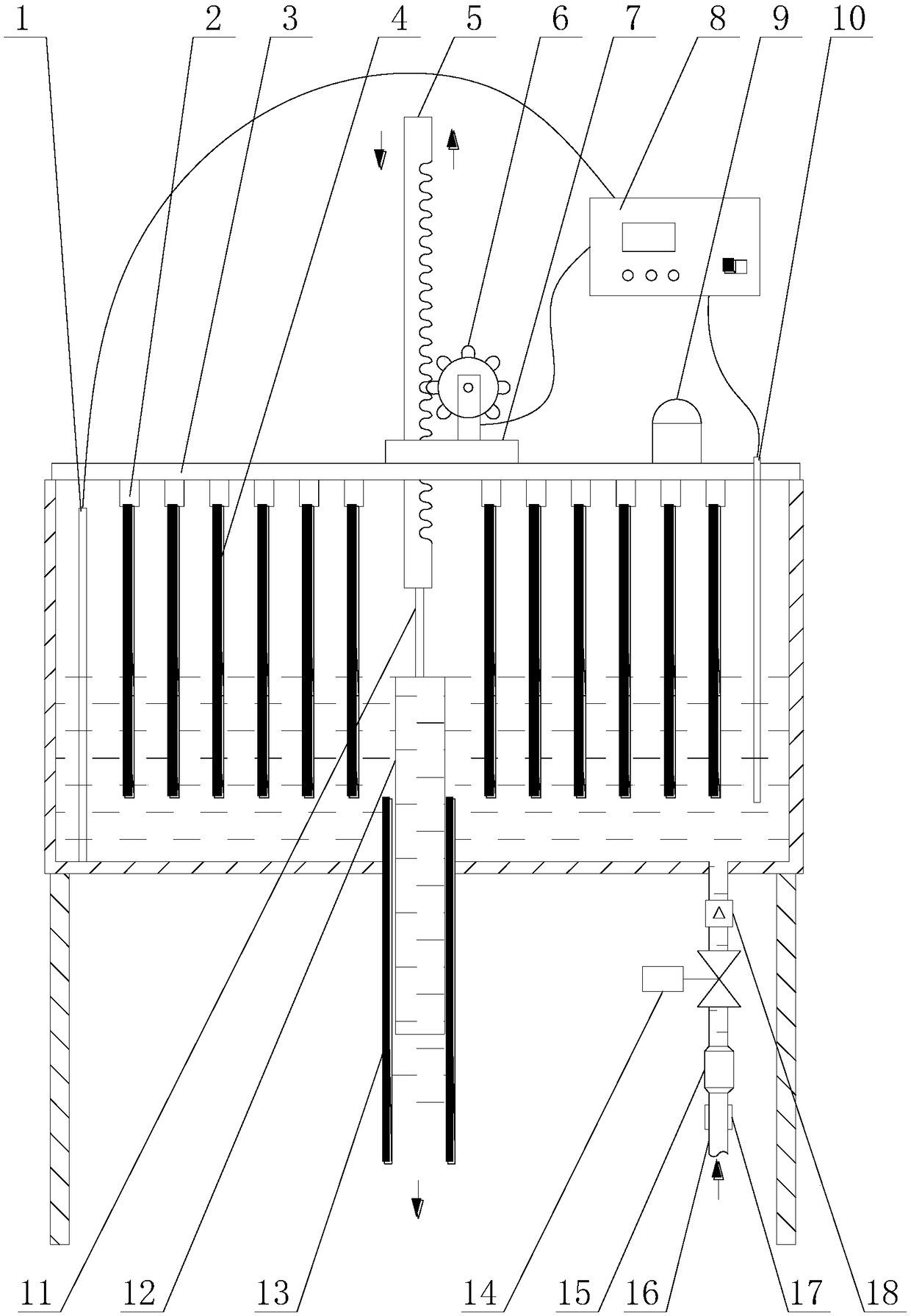

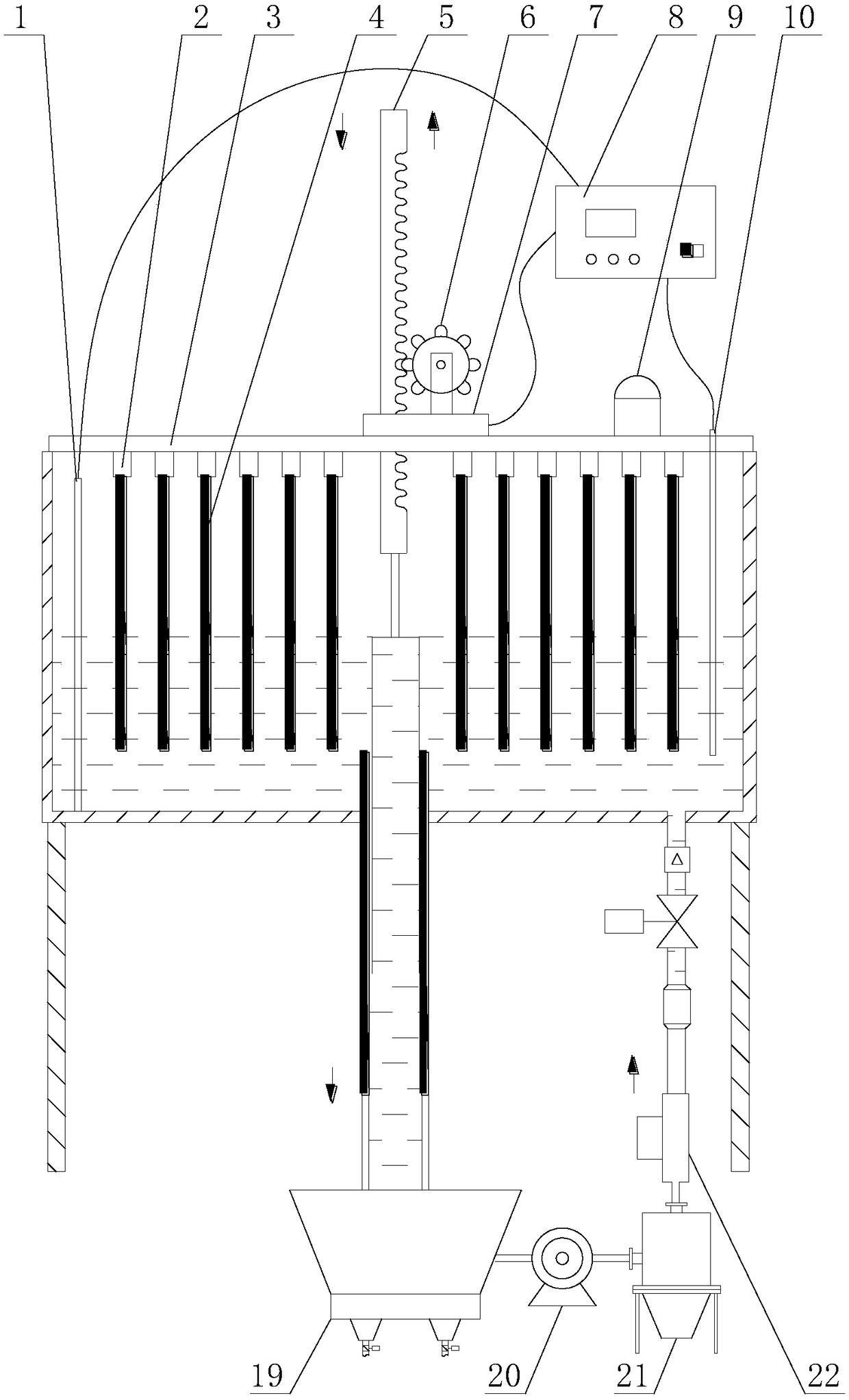

[0026] Embodiment 1: see figure 1 As shown, a water resistance load adjustment device includes a hollow water resistance box 3, the inside of the top plate of the water resistance box 3 is provided with a plurality of insulating fixing seats 2 for installing electrode plates 4, and the lower end of the electrode plates 4 is immersed in the water resistance the water in box 3. The bottom plate of the water resistance box 3 is provided with a drain pipe 13, and one end of the drain pipe 13 passes through the bottom plate and communicates with the cavity of the water resistance box 3. An overflow pipe 12 is sleeved inside the drain pipe 13 , and the outer wall at the bottom of the overflow pipe 12 is in movable and sealed connection with the inner wall at the top of the drain pipe 13 .

[0027] see figure 1 As shown, the outside of the top plate of the water resistance box 3 is provided with a lifting device, and the lifting end of the lifting device passes through the top plat...

Embodiment 2

[0029] Embodiment 2: on the basis of embodiment 1, refer to figure 1 As shown, the lifting device includes a transmission fixed seat 7 installed on the outside of the top plate of the water resistance box 3, a motor is installed on the transmission fixed seat 7, the output end of the motor is connected with the rack 5 through a gear 6, and the lower end of the rack 5 The movement passes through the transmission fixing seat 7 and is connected with the overflow pipe 12, and is used to drive the overflow pipe 12 to move up and down. The gear with self-locking function is connected with the rack drive, the upper and lower positions of the movable overflow pipe are changed, the water level of the water resistance box 3 is adjusted by controlling the height of the overflow pipe 12, and the water in the water resistance box 3 and the electrode plate are changed. 4, thereby changing the resistance value between the electrode plates 4 to meet the requirement of adjusting the power of t...

Embodiment 3

[0031] Embodiment 3: on the basis of embodiment 1, refer to figure 1 As shown, the adjustment device also includes an audible and visual alarm 9 and a temperature sensor 10 , the temperature sensor 10 is arranged in the water resistance box 3 , and the audible and visual alarm 9 and the temperature sensor 10 are electrically connected to the controller 8 respectively.

[0032] The temperature sensor 10 is used to detect the water temperature in the water resistance box 3, and transmits the detection signal to the controller 8, and the controller 8 automatically controls the opening of the regulating valve 14 according to the water temperature and preset temperature parameters. It can not only reduce the frequency of manual operation, realize fully automatic control, but also further improve the control stability and precision of the water resistance load. For example: the preset temperature is 70°C, and when the water temperature exceeds 70°C, the controller 8 appropriately ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com