A device that uses alternate filling or air extraction to realize the lamination of rubber shoe skirts

A technology for rubber shoes and fences, which is applied in the directions of shoe-making machinery, footwear, and applications, can solve problems such as uneven surfaces, non-fit of fences and shoes, and affecting the quality of shoes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

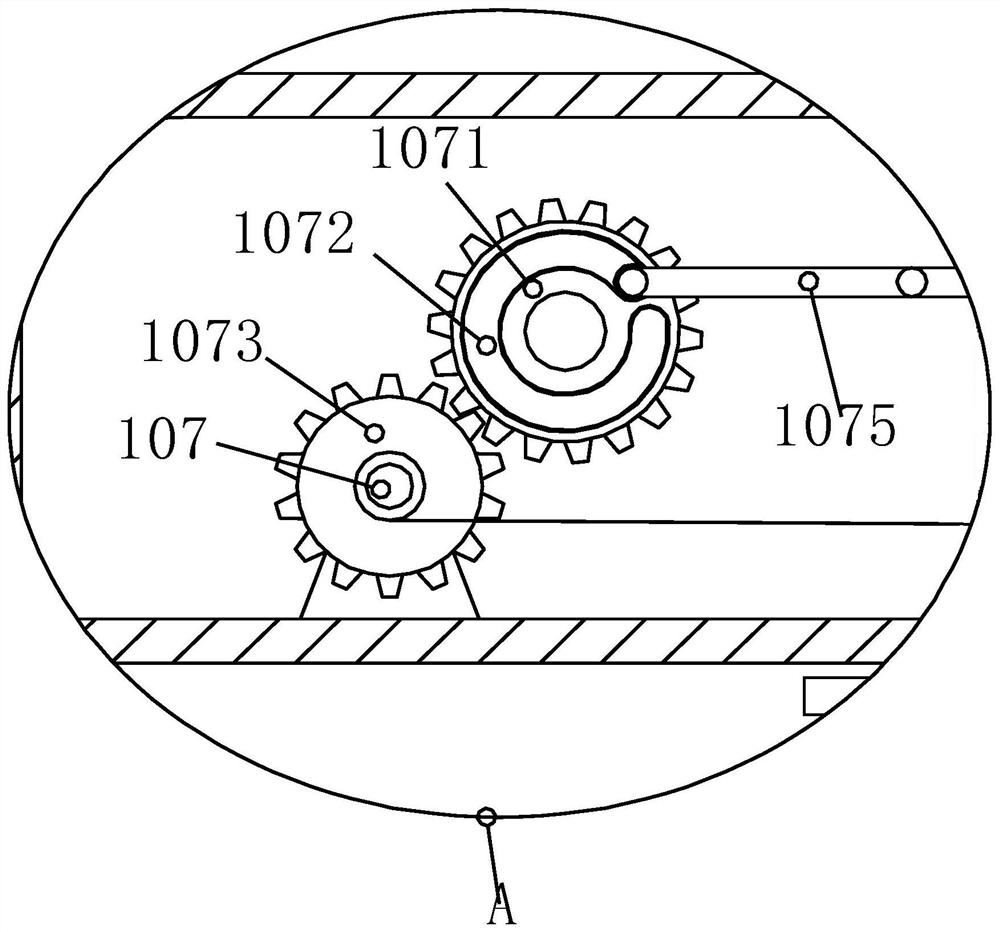

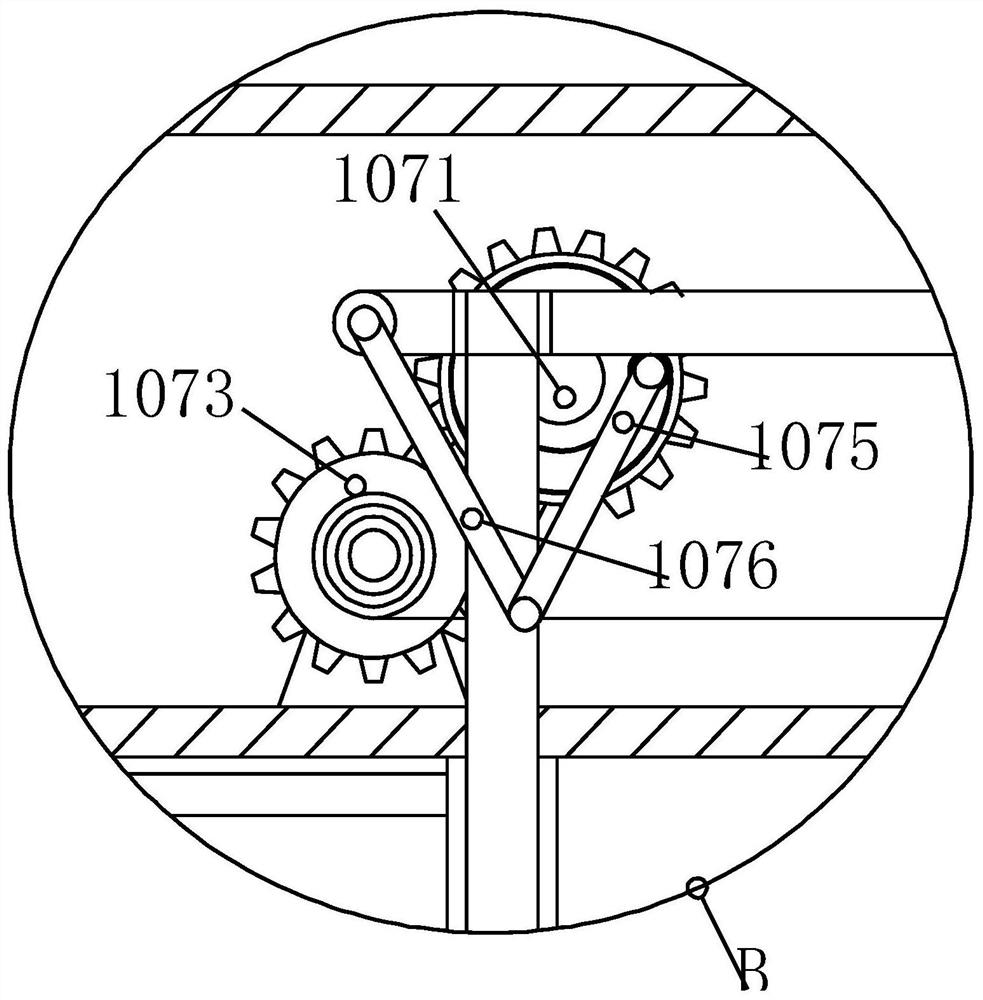

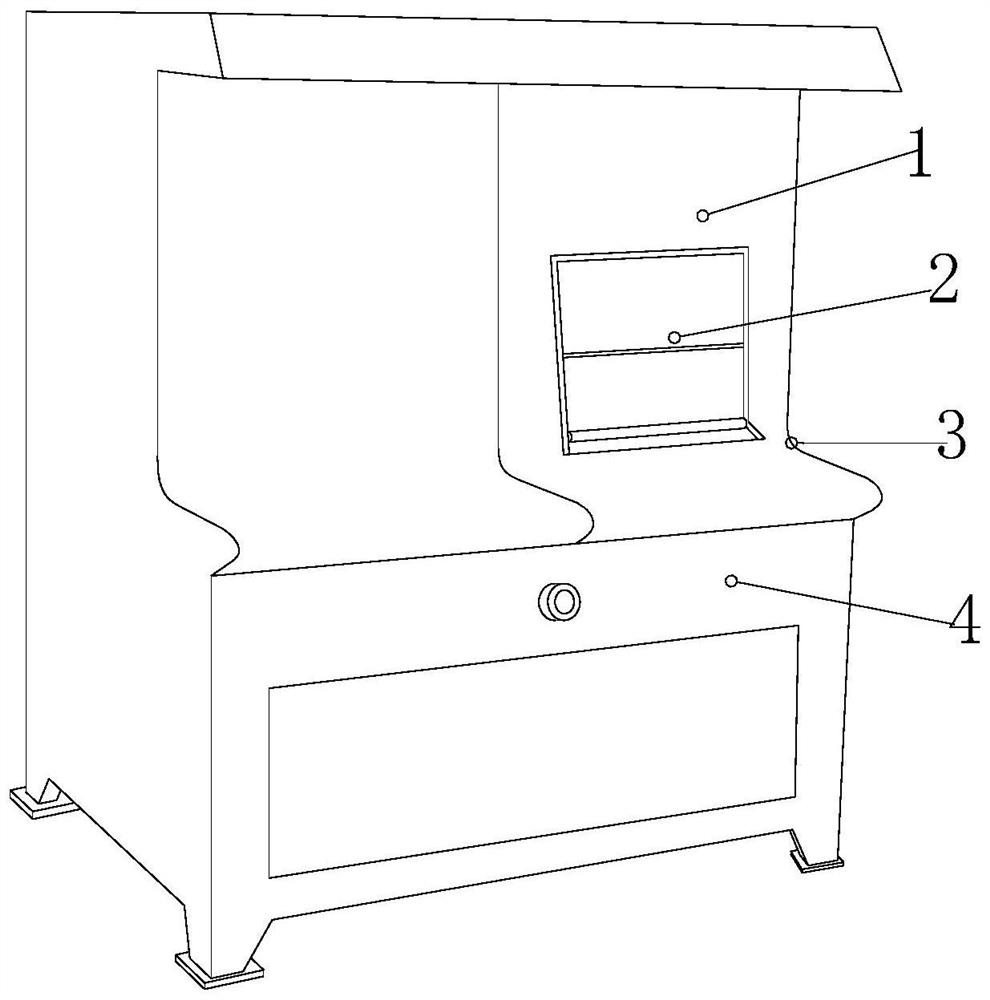

[0027] see Figure 1-Figure 8 , the present invention provides equipment for laminating rubber shoes skirts by alternately filling or extracting air. On one side of the panel, the access opening 2 runs through the housing 3, the housing 3 is arranged on the base 4, the housing 3 is fixedly connected to the base 4, and the pressing device 1 is installed in the housing 3 cavity.

[0028] The pressing device 1 is composed of a delivery tube 101, a driving mechanism 102, a storage chamber 103, a fixing mechanism 104, a working chamber 105, a first channel 106, a second channel control mechanism 107, a first spring 108, and a first fixed shaft 109. , a movable plate 110, a sealing cavity 111, and an air bag 112. The two ends of the delivery tube 101 communicate with the storage cavity 103 and the sealing cavity 111 respectively, and the storage cavity 103 is connected with the second channel control mechanism 107. The above-mentioned first spring 108 is arranged on the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com