Filter syringe and method

A technology for a syringe and a filter membrane, applied in the field of syringe filter devices, can solve the problems of troublesome repetitive operations, difficult automation, and easily blocked filters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

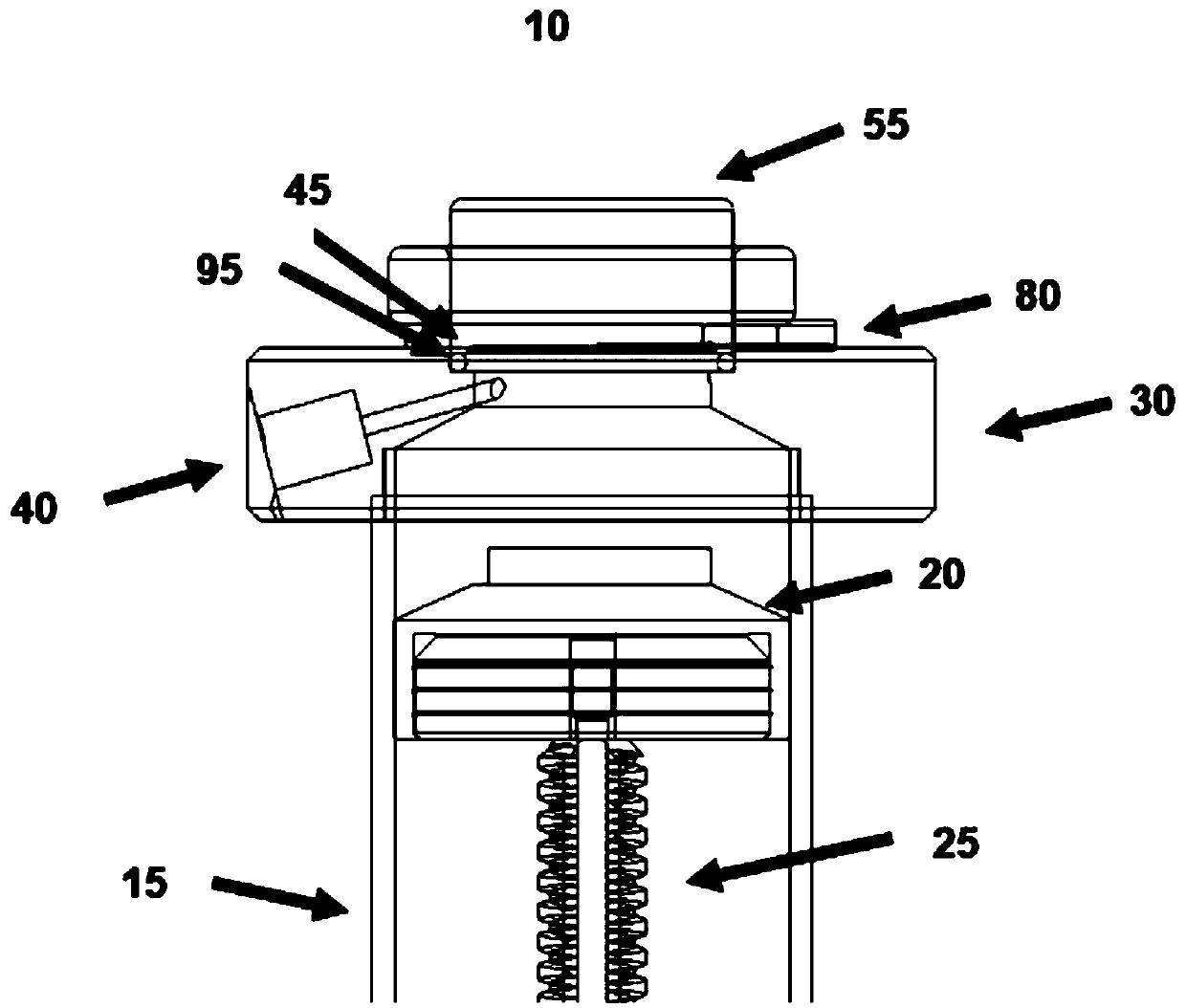

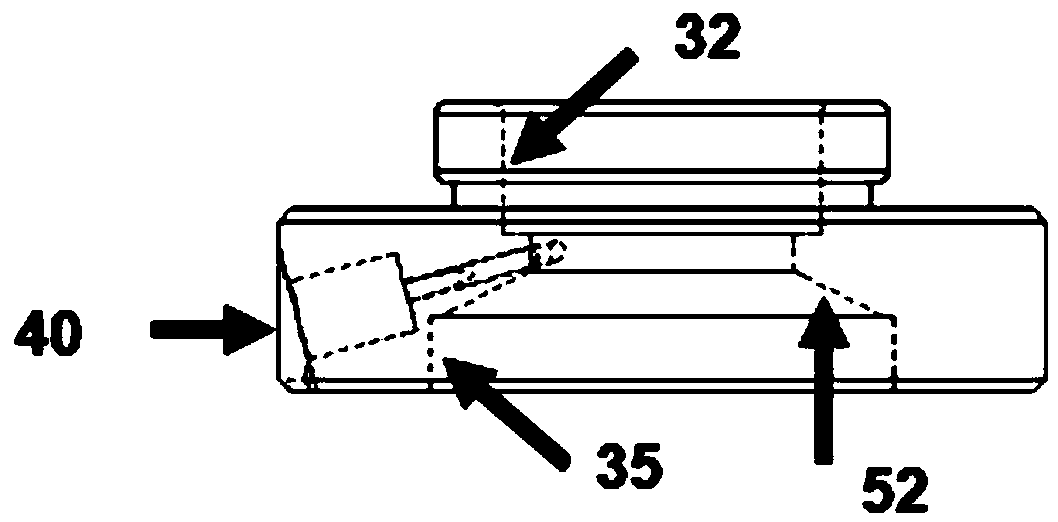

[0063] In a variant, see generally Figure 1 to Figure 15 , the syringe 10 has a cylindrical barrel 15, and a piston 20 connected to the piston rod 25, the piston 20 is fitted to be adapted to slide axially within the cylindrical barrel 15. The end cap 30 has a circular hole 35 at the bottom, which fits tightly on the cylinder 15 in an airtight and liquidtight manner. Top circular hole 32 is used to receive O-ring 95 , filter membrane 45 and stop cap 55 . The round hole 35 has a conical cone 52 .

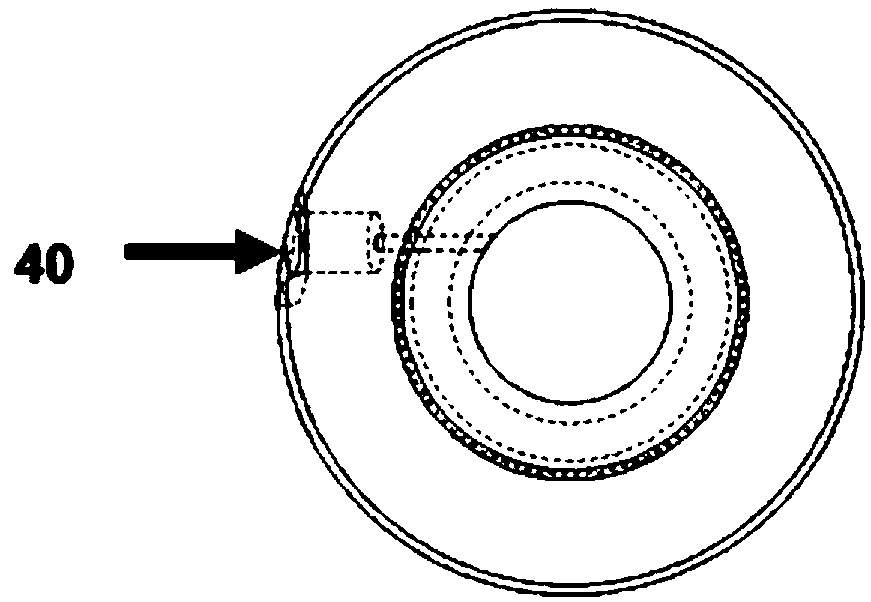

[0064] In another variant, such as Figure 2a As shown in -2b, the end cap 30 has an off-center inlet 40 on the side below the filter membrane surface 45 . The inlet 40 is sloped at an angle towards the filter membrane surface 45 . When the piston 20 slides down, due to the inclined position of the inlet 40, the liquid sample or solvent is sucked in from the inlet 40 and splashes the filter membrane 45, and because of its eccentric design, the liquid from the inlet 40 is generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com