Glue spraying clamp

A fixture and glue spraying technology, which is applied in the direction of spraying devices, coatings, and liquid coating devices on the surface, can solve the problems of moving pieces, unstable fixing of pieces, and inability to use common pieces, etc., and achieves strong applicability , the effect of preventing sagging deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described in conjunction with the following examples.

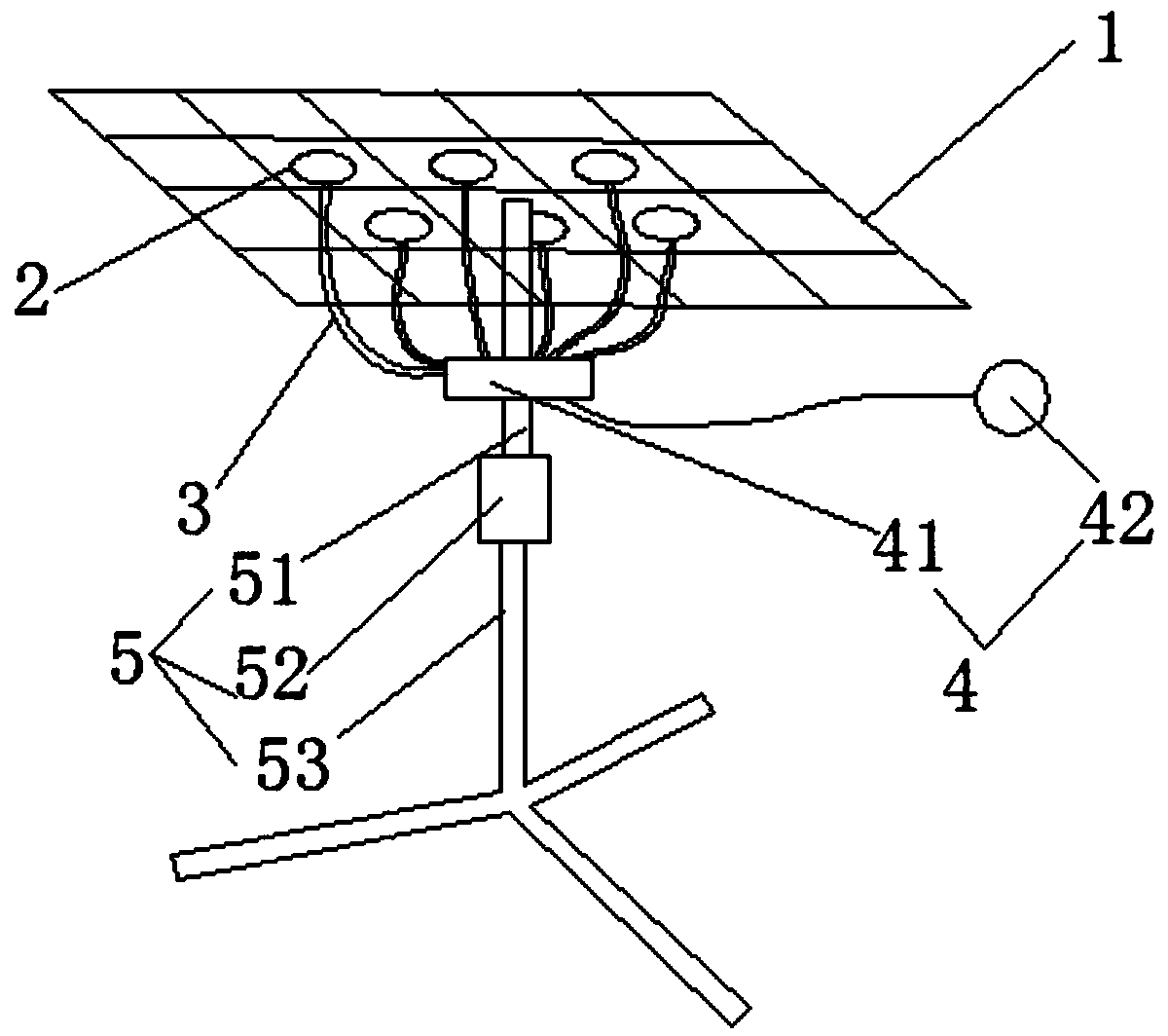

[0014] A specific embodiment of a glue spraying fixture of the present invention, such as figure 1 As shown, it includes a hollow bracket 1 , a rotating bracket 5 , a vacuum device 4 and a plurality of suction cups 2 . As a preferred solution, the rotating bracket 5 includes a fixed bracket 53 and a rotating rod 51. The middle part of the fixing bracket 53 extends upwards to a fixed post, and the bottom end of the rotating rod 51 is connected to the fixed post through a sleeve 52. Of course, except The sleeve 52 is selected, and the bearing can also be used as a rotating part for connection. The rotating end of the rotating bracket 5 (the top end of the rotating rod 51) is fixedly connected with the hollow bracket 1, and the vacuum device 4 is fixedly installed on the rotating bracket 5. Specifically, the vacuum device 4 can be fixedly installed on the rotating rod 51 or fixedly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com