A Method of Micro-air Explosion Grouting to Treat Large Porosity and Loose Foundation Soil

A large-pore, foundation soil technology, applied in soil protection, foundation structure engineering, construction, etc., can solve problems such as difficulty in pile formation, and achieve the effect of improving the uniformity of the pile body and expanding the penetration range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that the embodiments in the application and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

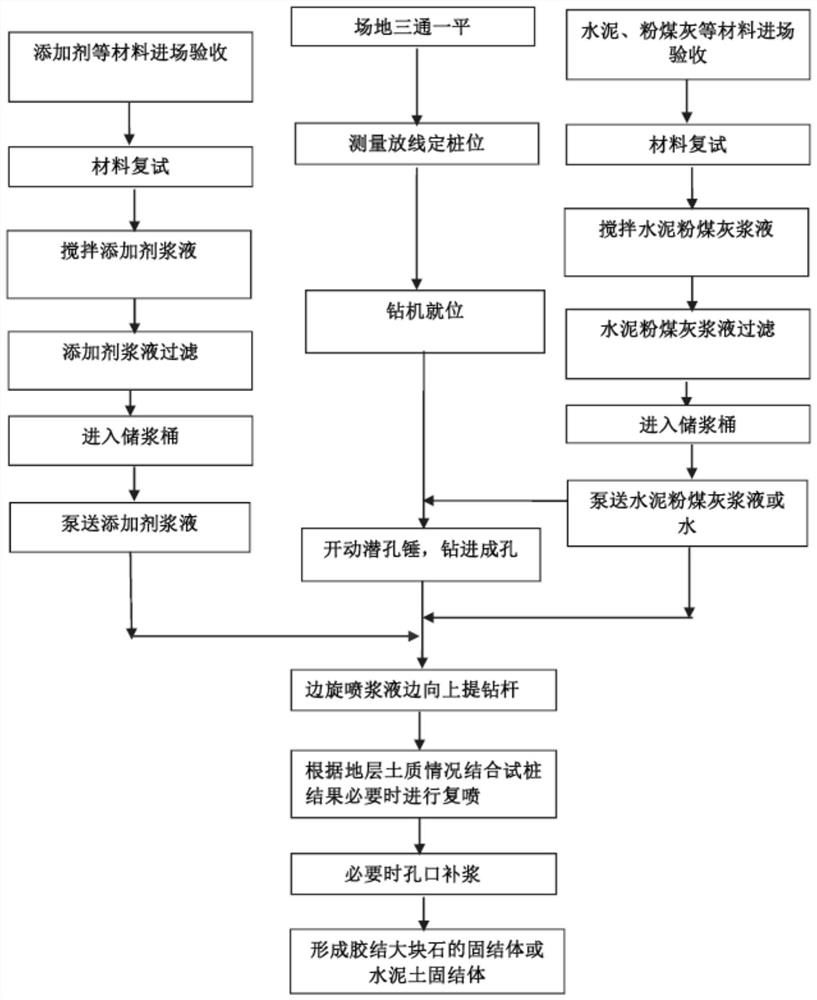

[0024] A method for micro-gas blasting grouting to treat large pores and loose foundation soil includes the following steps:

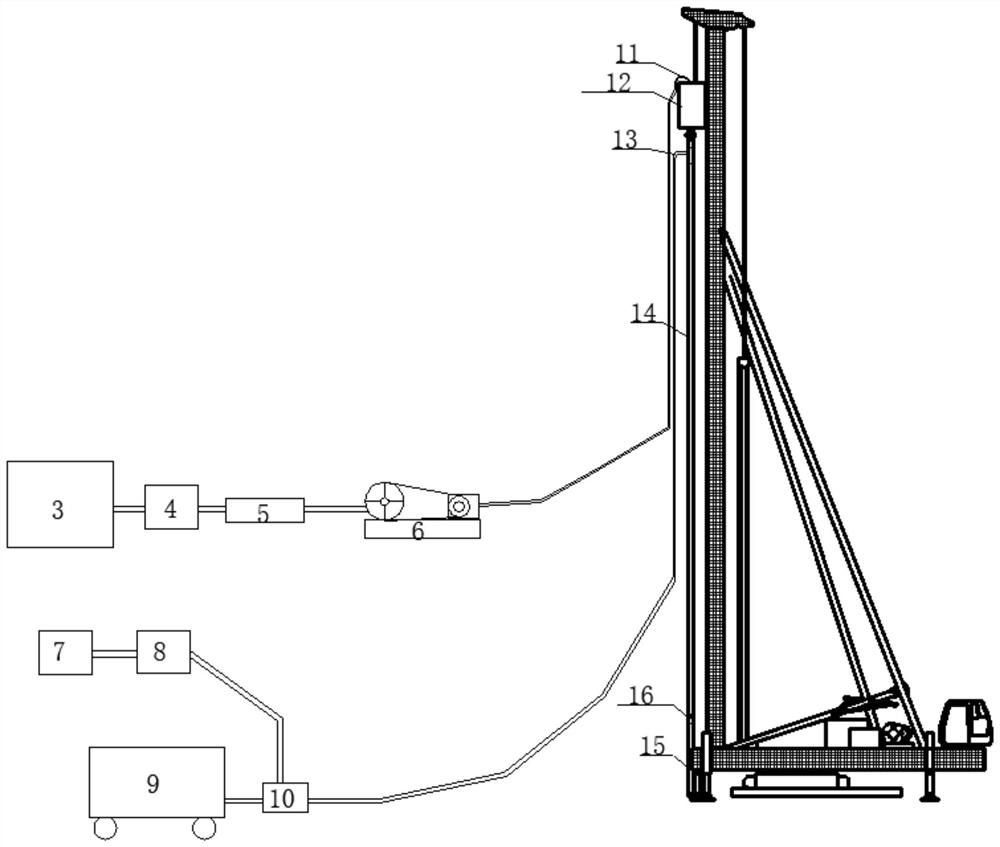

[0025] Step 1. Prepare cement fly ash slurry and additive slurry, and use down-the-hole hammer high-pressure rotary jet drilling rig to make holes;

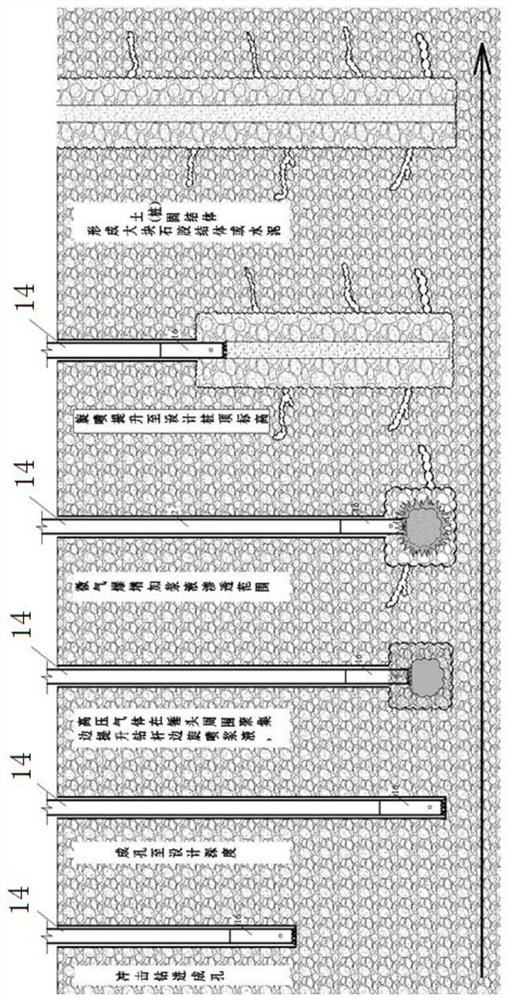

[0026] Step 2. Lift up the drill pipe 14 of the DTH hammer high-pressure rotary jet drilling rig, and at the same time, the nozzle 15 of the impact drill tool 16 of the DTH hammer high-pressure rotary jet drilling rig sprays high-pressure gas, the cement fly ash slurry and the additive slurry ,Such as Figure 1 to Figure 4 Shown.

[0027] The method for processing large pores and loose foundation soil according to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com